Oct . 31, 2024 12:37 Back to list

Diaphragm Seal Pressure Gauge Providers and Their Offerings

Understanding Diaphragm Seal Pressure Gauges A Guide for Suppliers

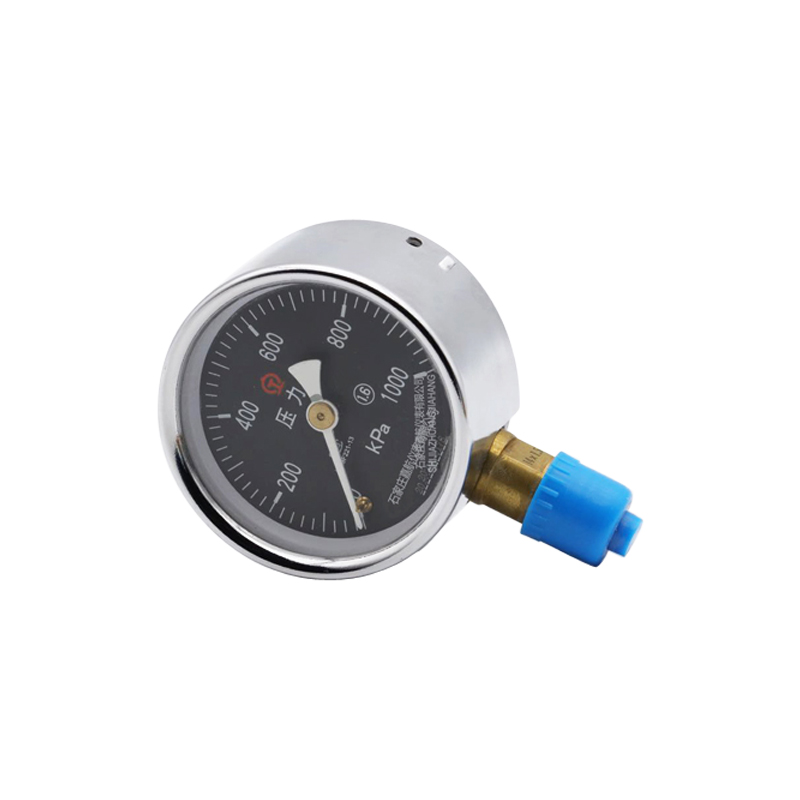

Diaphragm seal pressure gauges are crucial instruments used to measure pressure in various industrial applications. These devices are particularly beneficial in situations where the process fluid is corrosive, viscous, or contains solid particles. By incorporating a diaphragm seal, these gauges protect sensitive measuring components from direct exposure to harsh conditions, ensuring both accuracy and longevity.

What is a Diaphragm Seal Pressure Gauge?

At its core, a diaphragm seal pressure gauge consists of a traditional pressure gauge coupled with a diaphragm seal. The diaphragm is a flexible membrane that separates the process fluid from the gauge itself. When pressure from the fluid acts on the diaphragm, it causes it to deflect, which in turn translates this deflection into a readable pressure measurement. This design helps prevent corrosion, clogging, and contamination, making it an ideal choice for a range of industries, including chemical processing, food and beverage, pharmaceuticals, and oil and gas.

Benefits of Diaphragm Seal Pressure Gauges

1. Protection from Harsh Conditions The primary advantage of diaphragm seals is their ability to protect the gauge from corrosive fluids and high temperatures. This extends the life of the gauge and reduces the need for frequent replacements.

2. Maintenance of Accuracy By isolating the measuring element from the process media, diaphragm seal pressure gauges maintain accurate readings, even in challenging conditions. This reliability is critical for regulatory compliance and operational efficiency.

diaphragm seal pressure gauge suppliers supplier

3. Versatility These gauges can be adapted for various applications. Depending on the materials used for the diaphragm and seal, they can handle different types of fluids, including acids, bases, and viscous substances.

4. Reduced Pressure Pulsation Effects Diaphragm seals can also dampen pressure surges and pulsations, minimizing fluctuations in readings and improving overall performance.

Selecting a Supplier

When sourcing diaphragm seal pressure gauge suppliers, it's crucial to consider several factors

- Quality Standards Look for suppliers who adhere to recognized quality standards, ensuring that their products can withstand demanding conditions. - Customization Options Different applications may require specific configurations. Suppliers offering customized solutions can better meet unique client needs. - Technical Support Choose suppliers that provide comprehensive technical support and documentation, helping clients make informed decisions about their equipment.

- Reputation Research supplier reputation through customer reviews and industry feedback to ensure reliability and quality.

In conclusion, diaphragm seal pressure gauges play a vital role in ensuring accurate pressure measurements while providing protection against challenging process conditions. By carefully selecting a reputable supplier, industries can benefit from enhanced performance, prolonged gauge life, and increased operational efficiency. Whether it's for chemical processing, food production, or any other application, these gauges are indispensable tools for maintaining process integrity.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025