Nov . 07, 2024 22:11 Back to list

Suppliers of Diaphragm Seal Pressure Gauges for Accurate Measurement Solutions

Understanding Diaphragm Seal Pressure Gauges

In various industrial applications, especially in chemical, oil and gas, and food processing industries, the accurate measurement of pressure is crucial. One of the advanced instruments used for this purpose is the diaphragm seal pressure gauge. The diaphragm seal serves to protect the pressure sensing element from harsh environments, making these gauges highly reliable. This article will discuss the working principle of diaphragm seal pressure gauges, their advantages, and the top suppliers in the market.

Working Principle

A diaphragm seal pressure gauge utilizes a flexible diaphragm that separates the measuring fluid from the pressure sensing element. When pressure is applied to the diaphragm, it deflects, causing a proportional movement of the pressure sensing mechanism – usually a Bourdon tube or a strain gauge. This deflection is then translated into a readable pressure measurement on the gauge face.

The design ensures that the pressure sensing element is isolated from the process medium, thus preventing contamination and corrosion that could occur in environments with aggressive chemicals or high temperatures. The diaphragm can be made from various materials like stainless steel, Teflon, or other alloys, depending on the specific requirements of the application.

Advantages of Diaphragm Seal Pressure Gauges

1. Protection from Contaminants Diaphragm seal pressure gauges are particularly valuable when dealing with viscous, corrosive, or crystallizing media. The diaphragm acts as a barrier, ensuring that the sensing element remains clean and operational, prolonging the life of the gauge.

2. Improved Accuracy These gauges provide accurate measurements even under varying temperature and pressure conditions. By isolating the process medium, they reduce the chances of errors caused by fluctuations or sudden spikes in pressure.

3. Versatility Diaphragm seal gauges can be customized to suit a wide array of applications. They can handle different pressure ranges and operate effectively in various conditions, including extreme temperatures and pressures.

4. Reduces Maintenance Due to their robust design, diaphragm seal pressure gauges tend to require less maintenance. This is particularly beneficial in industries where equipment longevity and reliability are paramount, thus reducing operational costs.

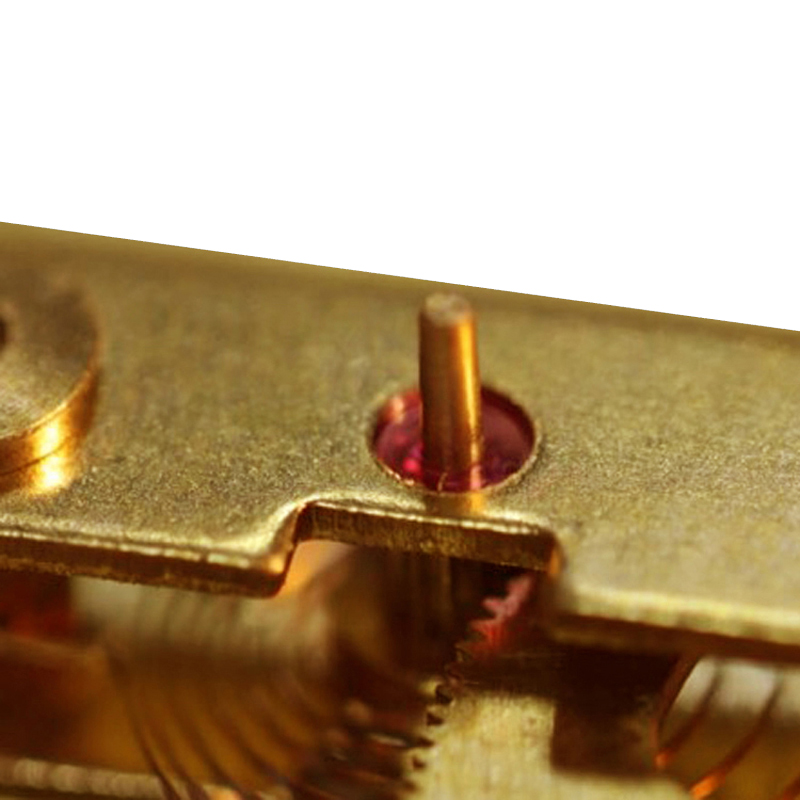

diaphragm seal pressure gauge suppliers jah

5. Enhanced Safety In industries dealing with hazardous materials, using diaphragm seal gauges minimizes the risk of leaks and spills by containing the process fluid away from the sensing components. This safety feature is crucial for compliance with health and safety regulations.

Top Suppliers of Diaphragm Seal Pressure Gauges

1. WIKA WIKA is a leading global supplier known for its high-quality pressure gauges, including diaphragm seal models. They offer a range of options to meet varying industry needs, with excellent customer support and service.

2. Ashcroft Ashcroft is renowned for its innovative pressure measurement solutions. Their diaphragm seal pressure gauges are designed for high accuracy and reliability, making them a preferred choice in challenging environments.

3. Emerson Emerson is another key player in the market, providing a broad spectrum of measurement solutions. Their diaphragm seal gauges are engineered for precision and durability, catering to a diverse array of industries.

4. Omega Engineering Omega provides an extensive range of pressure measurement devices, including diaphragm seal gauges. They offer customizable solutions that cater to unique application requirements, backed by robust technical support.

5. Honeywell Known for its advanced technologies, Honeywell supplies durable and efficient diaphragm seal pressure gauges. Their products are designed to meet strict safety and performance standards across various sectors.

Conclusion

Diaphragm seal pressure gauges are essential instruments in industries requiring precise pressure measurements under challenging conditions. Their ability to protect the sensing elements from harsh environments while ensuring reliable readings makes them a top choice among engineers and industry professionals. With reputable suppliers like WIKA, Ashcroft, Emerson, Omega Engineering, and Honeywell, finding high-quality diaphragm seal pressure gauges tailored to specific needs has never been easier. As industries continue to evolve, the demand for accurate and dependable pressure measurement tools will only increase, keeping diaphragm seal technologies at the forefront of industrial instrumentation.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025