Dec . 02, 2024 04:03 Back to list

Innovative Diaphragm Seal Pressure Gauges for Enhanced Accuracy and Reliability in Measurement

Understanding Diaphragm Seal Pressure Gauges

Pressure measurement is a fundamental aspect of many industrial applications, ensuring that systems operate within safe and efficient parameters. Among the various types of pressure measurement devices available, diaphragm seal pressure gauges stand out due to their unique design and functionality. This article will delve into what diaphragm seal pressure gauges are, their construction, applications, and benefits.

What is a Diaphragm Seal Pressure Gauge?

A diaphragm seal pressure gauge is a specialized type of pressure gauge that utilizes a flexible diaphragm as a barrier between the process fluid and the sensing element of the gauge. This design is particularly useful for measuring pressures in environments that are corrosive, viscous, or contain particulate matter. The diaphragm flexes in response to pressure changes, converting that mechanical movement into a readable gauge output.

Components of Diaphragm Seal Pressure Gauges

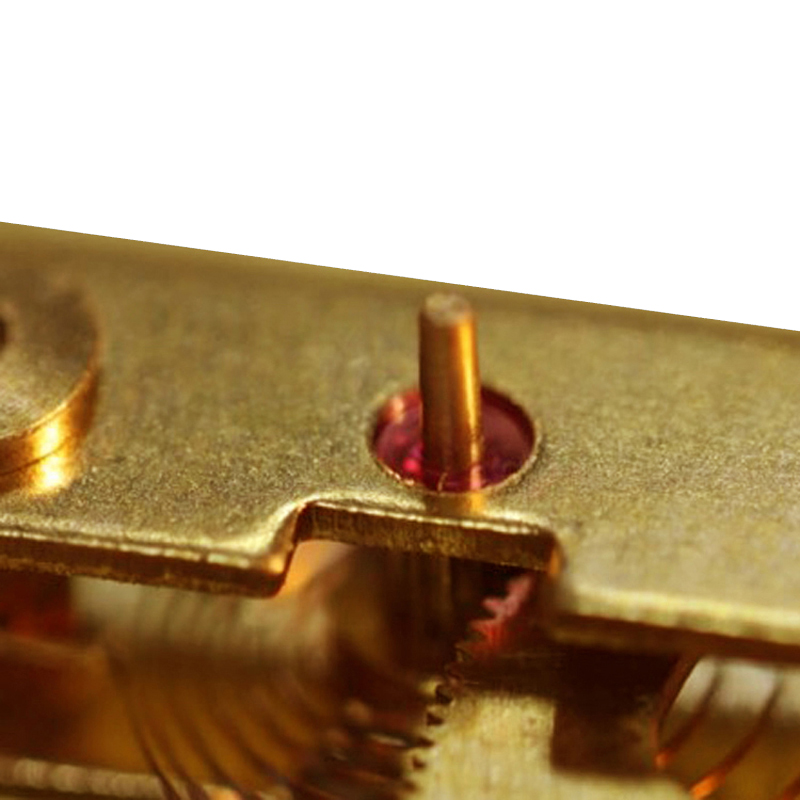

1. Diaphragm The central part of this gauge, usually made from materials like stainless steel or other corrosion-resistant alloys, which separates the process fluid from the sensing element.

2. Seal Housing Encloses the diaphragm and is connected to the process line. The housing is designed to withstand the conditions of the specific application, including temperature and pressure.

3. Filling Fluid Between the diaphragm and the sensing element, a filling fluid (often silicone oil) transmits the pressure exerted by the process fluid to the gauge.

5. Pressure Gauge Indicator The actual display that shows the pressure measurement, typically available in analog or digital formats.

Applications of Diaphragm Seal Pressure Gauges

diaphragm seal pressure gauges product

Diaphragm seal pressure gauges are utilized in various industries where standard gauges cannot perform effectively due to hostile conditions. Some common applications include

- Oil and Gas Measuring the pressure of corrosive fluids in wells and pipelines. - Chemical Processing Monitoring pressures of caustic chemicals or slurries that may clog or damage standard gauge mechanisms. - Food and Beverage Ensuring cleanliness and compliance with sanitary standards by preventing contamination from process media. - Pharmaceuticals Adhering to stringent hygiene standards while monitoring critical pressures. - Water Treatment Measuring pressures in media that may contain sediments or biological materials.

Benefits of Diaphragm Seal Pressure Gauges

1. Protection from Contaminants Diaphragm seals protect the gauge from corrosive or dirty fluids, extending its lifespan and ensuring accurate readings.

2. Versatility Suitable for a wide range of pressures and types of fluids, making them adaptable for various applications.

3. Safety By isolating the sensing element from the process fluid, diaphragm seal gauges minimize the risk of leaks or failures that could lead to hazardous situations.

4. Maintenance-Free Many diaphragm seal systems are designed to be maintenance-free, saving time and costs associated with regular monitoring and adjustments.

5. Improved Accuracy The use of filling fluids helps reduce the effects of temperature variations and vibration, contributing to more accurate pressure readings.

Conclusion

Diaphragm seal pressure gauges represent a crucial tool in the realm of pressure measurement, particularly in challenging environments where traditional gauges may fail. Their robust design, versatility, and ability to protect sensitive components make them indispensable across multiple industries. Whether observing the pressure in a chemical process or a wastewater treatment facility, diaphragm seal pressure gauges ensure safety, accuracy, and durability. As technology advances, these gauges continue to evolve, incorporating new materials and technologies to further enhance their performance and reliability. Understanding their functionality and benefits can help industries optimize their processes and maintain operational integrity.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025