Sep . 29, 2024 01:18 Back to list

Suppliers of Pressure Gauges with Diaphragm Sealing for Enhanced Accuracy and Reliability

Understanding Diaphragm-Sealed Pressure Gauges A Comprehensive Overview

Diaphragm-sealed pressure gauges are vital instruments used in various industries to measure the pressure of gases and liquids. Their unique design incorporates a diaphragm that provides a barrier between the measuring element and the process fluid, making them particularly useful in applications where the fluid might be corrosive, viscous, or otherwise damaging to standard gauges. This article will explore the benefits, applications, and considerations when selecting diaphragm-sealed pressure gauges, as well as an overview of suppliers in the market.

What are Diaphragm-Sealed Pressure Gauges?

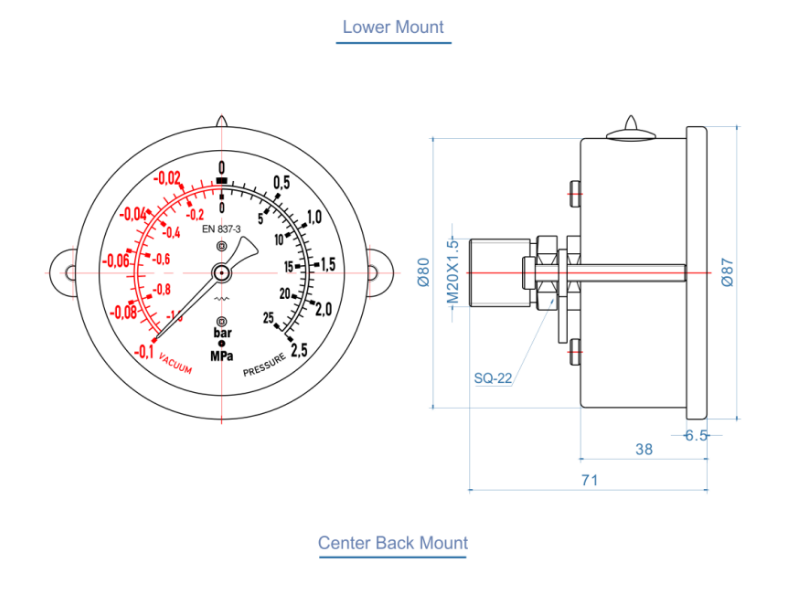

A diaphragm-sealed pressure gauge consists of a sensing diaphragm, typically made of materials like stainless steel, elastomers, or other compatible materials, which responds to pressure changes. When pressure is applied to the diaphragm, it flexes, causing a corresponding movement in the gauge's pointer or a digital reading in electronic models. The sealed design allows for accurate measurements in harsh environments without the risk of contamination or damage.

Benefits of Diaphragm-Sealed Pressure Gauges

1. Protection Against Corrosion One of the primary advantages of diaphragm-sealed gauges is their ability to protect the measuring element from corrosive fluids. The diaphragm acts as a barrier, ensuring that only the diaphragm is exposed to harmful substances.

2. Cleaning and Maintenance Many diaphragm-sealed gauges feature a smooth surface that is easy to clean. This makes them suitable for sanitary applications, particularly in the food and pharmaceutical industries.

3. Accuracy and Reliability These gauges are known for their accurate readings under various conditions, including fluctuating pressures. They provide reliable performance even in challenging environments.

4. Versatility Diaphragm-sealed pressure gauges come in various designs and configurations, making them suitable for a wide range of applications—from oil and gas to food processing and pharmaceuticals.

Applications of Diaphragm-Sealed Pressure Gauges

diaphragm sealed pressure gauges suppliers

Diaphragm-sealed pressure gauges are used across various sectors, including

- Chemical Processing They handle corrosive materials safely and accurately. - Pharmaceuticals Ensuring compliance with strict sanitary standards. - Food and Beverage Maintaining hygiene and avoiding contamination. - Petrochemical Measuring pressure in aggressive environments. - Water Treatment Monitoring pressure in treatment and distribution systems.

Choosing the Right Supplier

When it comes to sourcing diaphragm-sealed pressure gauges, selecting the right supplier is crucial for ensuring quality and reliability. Here are a few key factors to consider

1. Reputation Look for suppliers with a proven track record in the industry. Check customer reviews and testimonials.

2. Product Range A good supplier should offer a variety of pressure gauges, including different materials, sizes, and functionalities to meet your specific needs.

3. Technical Support Consider suppliers that provide technical assistance and guidance in selecting the right gauge for your application.

4. Standards and Certifications Ensure that the supplier’s products meet industry standards and have necessary certifications for your application.

5. After-Sales Service A robust after-sales service, including warranty and maintenance support, can be a significant advantage.

Conclusion

Diaphragm-sealed pressure gauges are essential tools in numerous industries, providing reliable and accurate pressure measurements while protecting sensitive components from damage. Understanding their benefits and applications can help businesses select the right gauge for their needs. Furthermore, choosing a reputable supplier is critical to ensure quality and support. As the demand for precise measurement continues to grow, diaphragm-sealed pressure gauges will remain crucial in enhancing operational efficiency and safety across various sectors. Whether you are in chemical processing, pharmaceuticals, food production, or any industry requiring precise pressure measurement, diaphragm-sealed gauges offer durable and dependable solutions.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025