Dec . 07, 2024 01:42 Back to list

diaphragm sealed pressure gauges manufacturer

Understanding Diaphragm Sealed Pressure Gauges and Their Manufacturers

In the world of industrial measurements, pressure gauges play a critical role in ensuring safety, efficiency, and performance across various applications. Among the different types of pressure gauges, diaphragm sealed pressure gauges hold a unique place due to their ability to measure pressure in challenging conditions. This article delves into the functionality, importance, and considerations when selecting manufacturers for diaphragm sealed pressure gauges.

What Are Diaphragm Sealed Pressure Gauges?

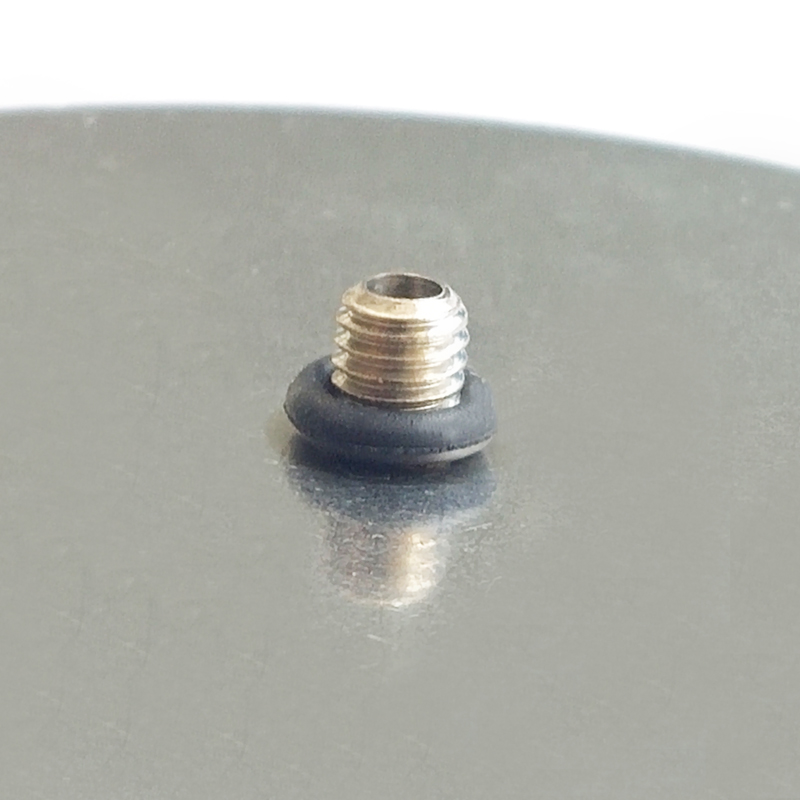

Diaphragm sealed pressure gauges are designed to measure the pressure of fluids while preventing the medium from directly contacting the measuring instrument. They utilize a flexible diaphragm that separates the measurement system from the process fluid. When pressure is applied to the fluid, it causes the diaphragm to deflect. This deflection is then translated into a pressure reading by the gauge.

The key advantage of diaphragm sealed pressure gauges is their ability to handle viscous, corrosive, and dirty media that might clog or damage traditional pressure gauges. They are widely used in industries such as oil and gas, chemicals, pharmaceuticals, food and beverage, and water treatment, where measurement accuracy and reliability are paramount.

Importance of Quality Manufacturing

The performance and longevity of diaphragm sealed pressure gauges are heavily influenced by the quality of their manufacture. Therefore, selecting a reputable manufacturer is crucial. Poorly manufactured gauges may lead to inaccurate readings, increased maintenance costs, or even catastrophic failures in high-stakes environments.

When evaluating manufacturers, it is essential to consider several factors

1. Material Quality The choice of materials directly affects the gauge's durability. Common materials include stainless steel, which resists corrosion, and special alloys for extreme conditions. A good manufacturer will offer a range of material options to suit different applications.

2. Design and Engineering Effective design plays a vital role in the performance of diaphragm sealed gauges. Manufacturers should provide gauges with adequate design features, such as burst protection and temperature compensation, tailored for specific applications.

diaphragm sealed pressure gauges manufacturer

3. Certification and Compliance Leading manufacturers adhere to international quality standards and certifications, such as ISO 9001. Compliance with industry-specific standards, such as those from the American Society of Mechanical Engineers (ASME) or the European Union’s PED (Pressure Equipment Directive), is also critical.

4. Customization Options Different applications may require unique specifications. A capable manufacturer can offer customization, including various pressure ranges, sizes, and styles, to meet specific operational needs.

5. Technical Support and Warranty A commitment to customer service, including providing technical support and a reasonable warranty, is a good indicator of a reliable manufacturer. This ensures that users receive assistance in troubleshooting and minimizes downtime.

Leading Manufacturers in the Industry

Several manufacturers are recognized for their expertise in producing diaphragm sealed pressure gauges. Companies like Wika, Ashcroft, and Omega Engineering have established themselves as leaders in the field. They offer a comprehensive portfolio of products backed by years of experience and a strong commitment to quality.

These manufacturers invest in advanced technology and research to enhance the accuracy and reliability of their gauges. They also provide extensive resources, including product documentation, installation guides, and technical assistance, to empower customers in making informed decisions.

Conclusion

Diaphragm sealed pressure gauges serve as essential tools in various industries, providing reliable measurements in challenging environments. When selecting a manufacturer, it is important to prioritize quality in materials, design, and customer service. The right producer not only guarantees the functionality of the pressure gauges but also assures safety and efficiency in critical operations.

As industries continue to evolve and face new challenges, the demand for high-quality diaphragm sealed pressure gauges will undoubtedly grow. Partnering with reputable manufacturers can help organizations maintain accuracy and reliability, leading to improved performance and safety in their operations. Always remember, the choice of manufacturer is a vital step toward ensuring effective measurement solutions in today's complex industrial landscape.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025