Dec . 28, 2024 20:00 Back to list

Diaphragm Sealed Pressure Gauges Manufacturing and Quality Assurance Practices

Understanding Diaphragm Sealed Pressure Gauges A Focus on Factories and Manufacturing

Diaphragm sealed pressure gauges are essential instruments in various industrial applications where accurate pressure measurement is crucial. Unlike standard pressure gauges, diaphragm sealed gauges are designed to withstand harsh environments, protecting sensitive components from corrosive, viscous, or high-temperature media. This functionality makes them increasingly popular in industries such as oil and gas, chemical processing, food and beverage, and pharmaceuticals.

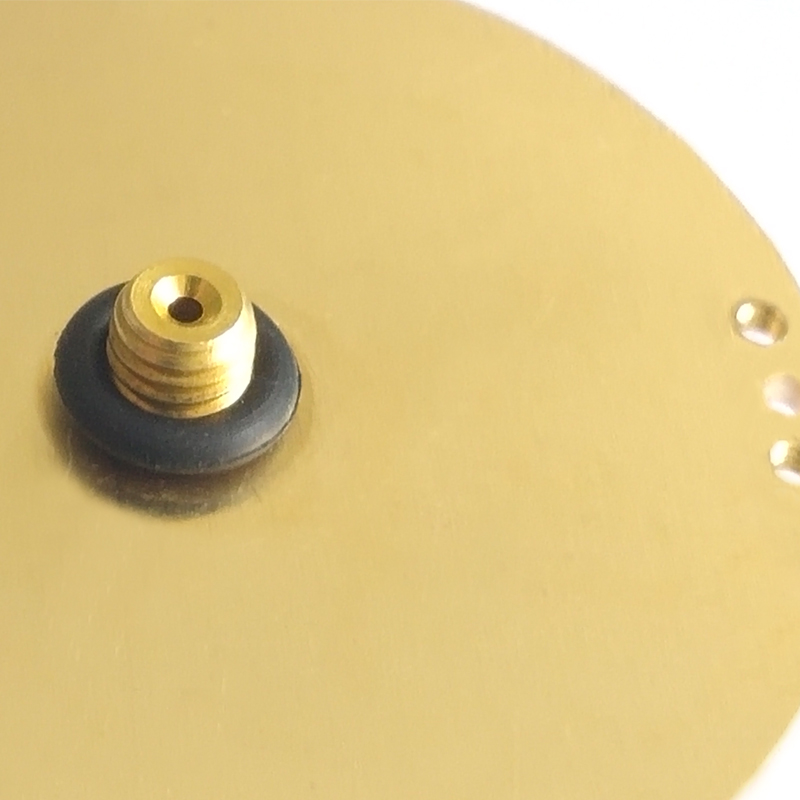

The core component of a diaphragm sealed pressure gauge is its diaphragm, typically made from materials such as stainless steel or other corrosion-resistant alloys. The diaphragm acts as a barrier between the process media and the gauge mechanism, ensuring the internal workings are shielded from potentially damaging substances. This design not only increases the gauge's lifespan but also enhances measurement accuracy, making it a preferred choice for manufacturers.

Manufacturing Process

The manufacturing of diaphragm sealed pressure gauges involves several intricate steps, each of which plays a significant role in achieving a high-quality final product.

1. Material Selection The first step in the manufacturing process is selecting appropriate materials. The diaphragm must be robust yet flexible enough to respond to pressure changes. Common materials include 316 stainless steel, Monel, and other alloys that can withstand high pressures and corrosive environments.

2. Diaphragm Fabrication The selected materials are then formed into diaphragms. This can involve processes like stamping or deep drawing. Precision is key here, as the diaphragm must be uniform and capable of providing accurate measurements across its range.

3. Assembly Once the diaphragms are prepared, they are assembled with the gauge mechanism. The assembly process must be performed under controlled conditions to prevent contamination and ensure that seals are tight.

diaphragm sealed pressure gauges factories

4. Calibration Following assembly, the gauges undergo a rigorous calibration process. This step is vital to ensure that each gauge provides precise readings. Calibration involves comparing the gauge’s readings against known pressure standards and making necessary adjustments.

5. Quality Control Before the final product reaches the market, it undergoes comprehensive quality control inspections. This includes testing for leaks, checking pressure response times, and verifying that all components meet specifications.

Importance of Factories in Production

Factories play a crucial role in the efficient production of diaphragm sealed pressure gauges. Advanced manufacturing facilities equipped with modern technology streamline the fabrication processes, enhance precision, and reduce costs. The incorporation of automation in manufacturing has led to higher throughput and consistency in quality.

Moreover, factories specializing in pressure gauge production often engage in research and development. They continually seek to innovate and improve their products to meet the ever-evolving needs of various industries. This commitment to advancement not only benefits the manufacturers but also ensures that end users receive the most reliable and accurate instruments available.

Conclusion

In conclusion, diaphragm sealed pressure gauges represent a critical component in various industrial processes where precision and durability are paramount. The role of factories in their production cannot be overstated; through careful material selection, detailed fabrication, thorough calibration, and rigorous quality control, manufacturers can provide reliable instruments that meet the demands of diverse applications. As industries continue to evolve and require more sophisticated measurement tools, the importance of these gauges and the factories that produce them will only continue to grow.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025