Oct . 06, 2024 16:30 Back to list

diaphragm sealed pressure gauge company

Understanding Diaphragm-Sealed Pressure Gauges

Diaphragm-sealed pressure gauges are essential instruments in various industries, particularly in sectors that deal with corrosive or viscous fluids, high-purity processes, or extreme environmental conditions. These gauges serve the primary purpose of measuring pressure accurately while providing durability and protection against harsh conditions, making them ideal for demanding applications.

How Diaphragm-Sealed Pressure Gauges Work

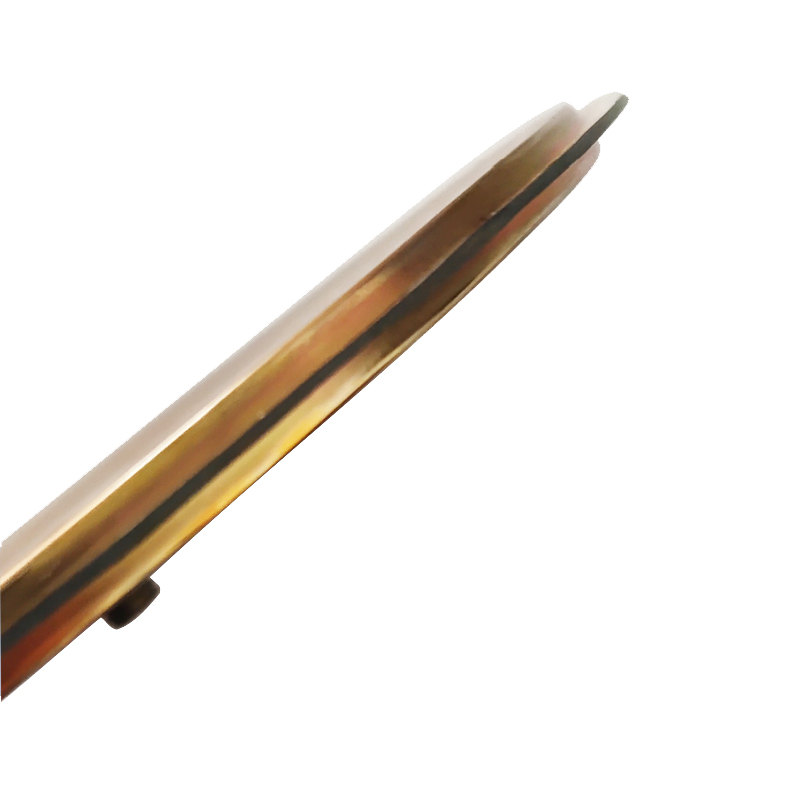

At the heart of diaphragm-sealed pressure gauges is a flexible diaphragm, a thin membrane that deflects when subjected to pressure. When pressure is applied, the diaphragm bends, and this deflection is converted into a readable output, often displayed on a dial or digital readout. The design encapsulates the internal components, protecting them from the medium being measured, which is particularly important in scenarios involving aggressive chemicals or slurries.

This sealing mechanism not only prevents contact between the process fluid and the gauge interior but also eliminates the possibility of blockages, which can occur with conventional gauges. The importance of this feature cannot be overstated, especially in processes requiring stringent cleanliness and accuracy.

Applications of Diaphragm-Sealed Pressure Gauges

Diaphragm-sealed pressure gauges find their applications across various domains, including

1. Chemical Processing In chemical manufacturing, the gauges provide reliable pressure readings while resisting corrosive agents. This ensures the safety and efficiency of processes involving aggressive chemicals.

2. Pharmaceuticals For the pharmaceutical industry, purity is paramount. Diaphragm-sealed gauges offer a contamination-free environment for pressure measurement, crucial in drug manufacturing and handling.

3. Food & Beverage Maintaining food safety standards is essential. These gauges help monitor pressure in processes without risking contamination, supporting compliance with health regulations.

4. Petrochemical In the harsh environments of oil and gas extraction, diaphragm-sealed gauges withstand extreme pressures and temperatures, ensuring reliability and accuracy in measurement.

5. Water Treatment In water filtration systems, these gauges help monitor pressure across different stages of treatment, ensuring optimal performance and spotting potential issues before they escalate.

Advantages of Diaphragm-Sealed Pressure Gauges

The diaphragm-sealed pressure gauge offers numerous advantages

diaphragm sealed pressure gauge company

- Protection from Contaminants The sealed design prevents the ingress of dirt, dust, and other contaminants, prolonging the gauge's lifespan and maintaining accuracy.

- Reduced Maintenance Since the gauge is protected from the process fluid, maintenance requirements are significantly reduced compared to traditional gauges.

- Wide Range of Compatibility These gauges can be designed to accommodate various pressures, temperatures, and materials, adapting to the needs of different applications.

- Enhanced Safety By minimizing the risk of leaks and ruptures, diaphragm-sealed gauges contribute to safer operations in potentially hazardous environments.

Choosing the Right Diaphragm-Sealed Pressure Gauge

When selecting a diaphragm-sealed pressure gauge, several factors should be considered

1. Material Compatibility It is crucial to select a diaphragm material that is compatible with the process fluid to prevent corrosion or chemical reaction.

2. Pressure Range Understanding the expected pressure range helps in choosing a gauge that operates effectively within those parameters.

3. Accuracy Requirements Depending on the application, specific precision levels may be necessary, making it vital to select a gauge that meets those needs.

4. Size and Connection Type Consider the size of the gauge and the connection type required for integration into existing systems.

5. Certifications and Standards Ensure that the selected gauge meets industry standards and certifications specific to the application, particularly in highly regulated sectors like pharmaceuticals or food processing.

Conclusion

Diaphragm-sealed pressure gauges are indispensable tools for accurately measuring pressure in challenging environments. With their robust design and protection against corrosive substances, these gauges enhance safety, efficiency, and reliability across various industries. As technology advances, the design and functionality of diaphragm-sealed pressure gauges continue to improve, further solidifying their role in ensuring optimum performance in critical applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025