Dec . 10, 2024 08:24 Back to list

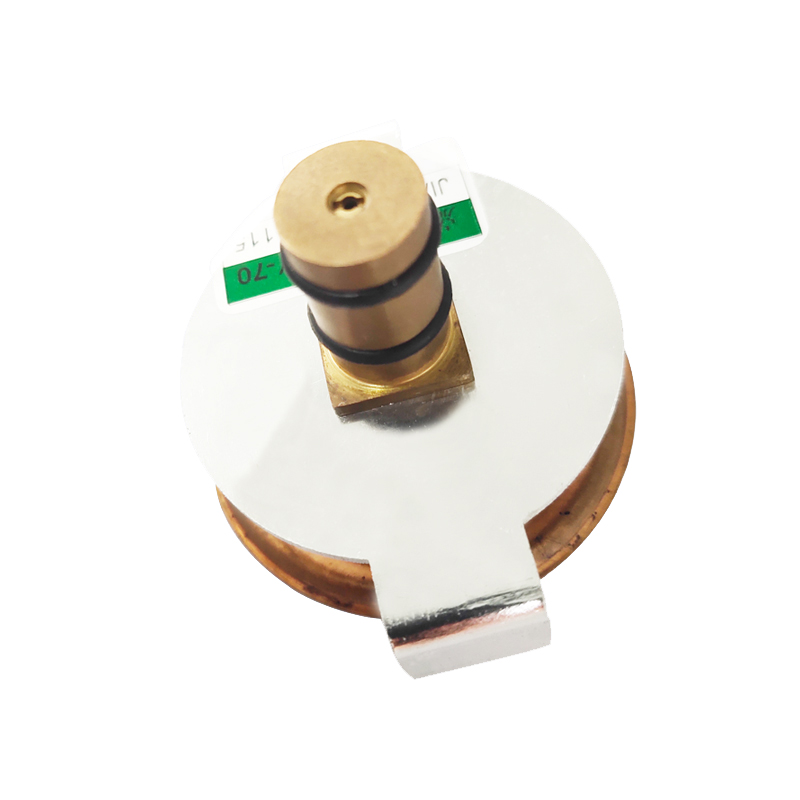

diaphragm pressure guage jah

Understanding Diaphragm Pressure Gauges

In various industrial and scientific applications, measuring pressure accurately is critical for ensuring operational efficiency and safety. One of the most reliable tools for pressure measurement is the diaphragm pressure gauge. This article delves into the function, advantages, and applications of diaphragm pressure gauges, focusing on the Jah brand, known for its quality and precision.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge is a device that measures pressure by deforming a flexible membrane or diaphragm in response to pressure changes. When pressure is applied, the diaphragm bends and converts this mechanical displacement into a rotational movement. This movement drives a dial or electronic sensor that displays the pressure reading. Diaphragm gauges are particularly suited for measuring low to moderate pressures and are commonly used in gas and liquid applications.

Advantages of Diaphragm Pressure Gauges

1. Accuracy Diaphragm pressure gauges provide accurate pressure readings, which are crucial in maintaining optimal conditions in various processes. The design allows for minimal hysteresis and high repeatability.

2. Wide Range of Applications These gauges are versatile and can be used in multiple industries, including oil and gas, food and beverage, pharmaceuticals, and water treatment. They are effective in measuring both corrosive and non-corrosive media.

3. Robust Construction Diaphragm pressure gauges are built to withstand harsh conditions. The materials used, such as stainless steel, are resistant to corrosion and physical impact, ensuring durability and longevity.

4. Minimal Maintenance Due to their simple design and robust construction, diaphragm pressure gauges require less maintenance compared to other types of pressure measuring devices, which helps reduce operational costs.

diaphragm pressure guage jah

5. Compact Design Their compact size allows for easy integration into systems where space is limited, without compromising performance.

The Jah Brand A Benchmark in Quality

Jah is a recognized name in the industry for manufacturing high-quality diaphragm pressure gauges. The brand is known for its rigorous quality control processes and commitment to innovation. Jah diaphragm pressure gauges are engineered for performance and longevity, featuring advanced materials and state-of-the-art manufacturing techniques. With Jah's reputation for reliability, many industries trust their products for critical pressure measurement.

Applications of Diaphragm Pressure Gauges

Diaphragm pressure gauges have a myriad of applications. In the oil and gas industry, they are used to monitor pipeline pressures, ensuring safe and efficient transportation of resources. In the food and beverage sector, these gauges are essential for monitoring processes to maintain product quality and safety.

In pharmaceutical applications, precise pressure control is vital for ensuring product integrity, where diaphragm gauges help to monitor and control the conditions during manufacturing. Furthermore, in water treatment facilities, diaphragm pressure gauges assist in maintaining optimal pressure levels in various treatment processes, contributing to effective water purification and distribution.

Conclusion

Diaphragm pressure gauges, particularly those by the Jah brand, stand out for their accuracy, durability, and versatility across multiple industries. Their ability to deliver precise pressure readings while requiring minimal maintenance makes them an invaluable tool in modern industrial processes. As industries continue to advance and evolve, diaphragm pressure gauges will undoubtedly remain a fundamental component in ensuring safety, efficiency, and quality in pressure measurement. Whether it’s in oil and gas, pharmaceuticals, or food processing, the reliability of diaphragm pressure gauges is undeniable, shaping the future of pressure monitoring technology.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025