Nov . 24, 2024 20:04 Back to list

Understanding Diaphragm Pressure Gauges for Accurate Measurements in Various Applications

Understanding Diaphragm Pressure Gauges An Essential Tool in Pressure Measurement

In various industrial applications, the accurate measurement of pressure is critical for ensuring safety, efficiency, and overall operational effectiveness. One of the most widely used instruments for this purpose is the diaphragm pressure gauge. This device is designed to measure the pressure of gases and liquids, providing precise readings that help in monitoring and controlling processes.

What is a Diaphragm Pressure Gauge?

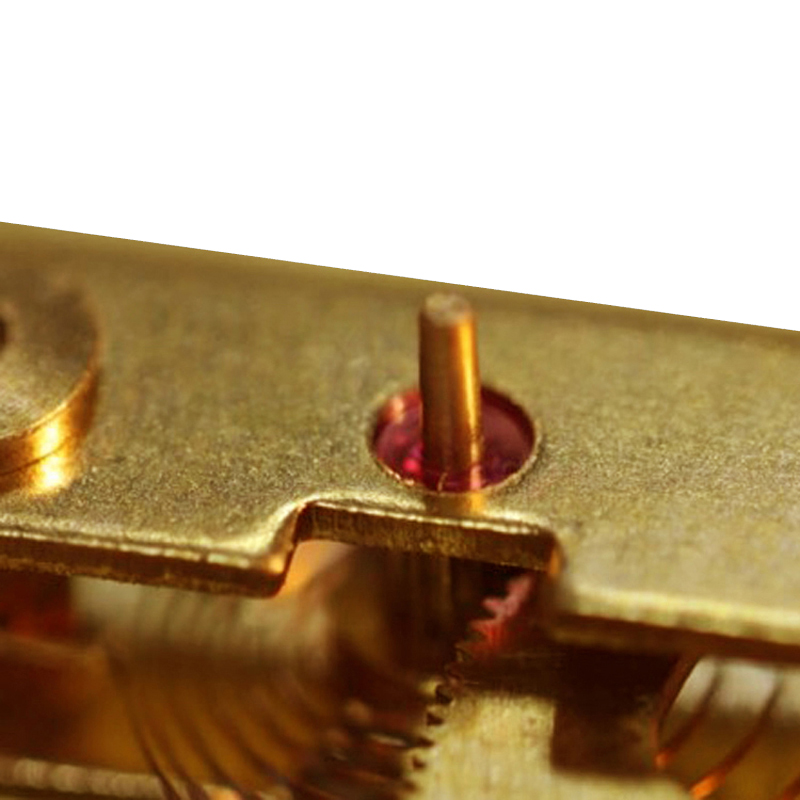

A diaphragm pressure gauge consists of a flexible diaphragm located within a pressure chamber. When pressure is applied, the diaphragm deflects, and this deflection is translated into a readable value on a scale. The primary components of a diaphragm pressure gauge include the diaphragm, a casing, a movement mechanism, and a dial. The diaphragm is typically made from materials such as stainless steel or other alloys, which offer durability and resistance to various chemicals.

How Does It Work?

The working principle of a diaphragm pressure gauge is relatively straightforward. As the internal pressure acting on the diaphragm increases, it bends or moves from its neutral position. This movement is proportional to the applied pressure. The mechanical movement of the diaphragm is connected to a system of levers or a pointer mechanism that translates the movement into a readable gauge value. Diaphragm gauges can be used for both absolute and gauge pressure measurements, depending on their design.

Advantages of Diaphragm Pressure Gauges

1. High Accuracy One of the primary advantages of diaphragm pressure gauges is their accuracy. These gauges can measure very low pressures and provide consistent results, making them ideal for applications requiring precision.

2. Wide Range of Applications Diaphragm pressure gauges are versatile and can be used across various industries, including oil and gas, chemical processing, food and beverage, and pharmaceuticals. Their ability to measure both gases and liquids enhances their applicability.

diaphragm pressure guage

3. Corrosion Resistance Many diaphragm gauges are designed with materials that resist corrosion, making them suitable for harsh environments and chemical applications. This enhances their lifespan and reduces maintenance needs.

4. Compact Design The design of diaphragm pressure gauges is generally compact, allowing them to fit into tight spaces where other types of gauges may not be practicable.

Limitations to Consider

While diaphragm pressure gauges offer numerous benefits, there are some limitations to consider. For instance, they may not perform well under extreme temperatures or in conditions with high vibrations. Moreover, if the gauge is subjected to pressure levels beyond its maximum rating, it can lead to damage or inaccuracy.

Maintenance and Calibration

To ensure optimal performance, regular maintenance and calibration of diaphragm pressure gauges are essential. This includes routine checks for accuracy and functionality, as well as inspection for any signs of wear or damage. Calibration should be performed according to the manufacturer's specifications and recommendations to maintain the gauge's reliability.

Conclusion

Diaphragm pressure gauges are indispensable instruments in many industries where pressure monitoring plays a crucial role. Their accuracy, versatility, and robust construction make them a preferred choice for both simple and complex pressure measurement tasks. Understanding the capabilities and operational mechanisms of diaphragm pressure gauges enables industries to choose the right gauge for their specific needs, thus enhancing safety and efficiency in their operations. Whether you are in manufacturing, process control, or instrumentation, diaphragm pressure gauges will likely remain a staple tool in your equipment arsenal.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025