Nov . 14, 2024 07:47 Back to list

diaphragm pressure gauge wika factory

Understanding Diaphragm Pressure Gauges A Focus on WIKA's Manufacturing Excellence

Pressure measurement is a critical aspect of numerous industrial applications, and accurately measuring this parameter is essential for safety, efficiency, and overall process control. Among the various types of pressure gauges available, diaphragm pressure gauges have gained recognition for their precision and durability. WIKA, a leading manufacturer in the instrumentation sector, has established itself as a prominent provider of diaphragm pressure gauges. This article delves into the principles of diaphragm pressure gauges, their applications, and what sets WIKA apart in this competitive market.

What is a Diaphragm Pressure Gauge?

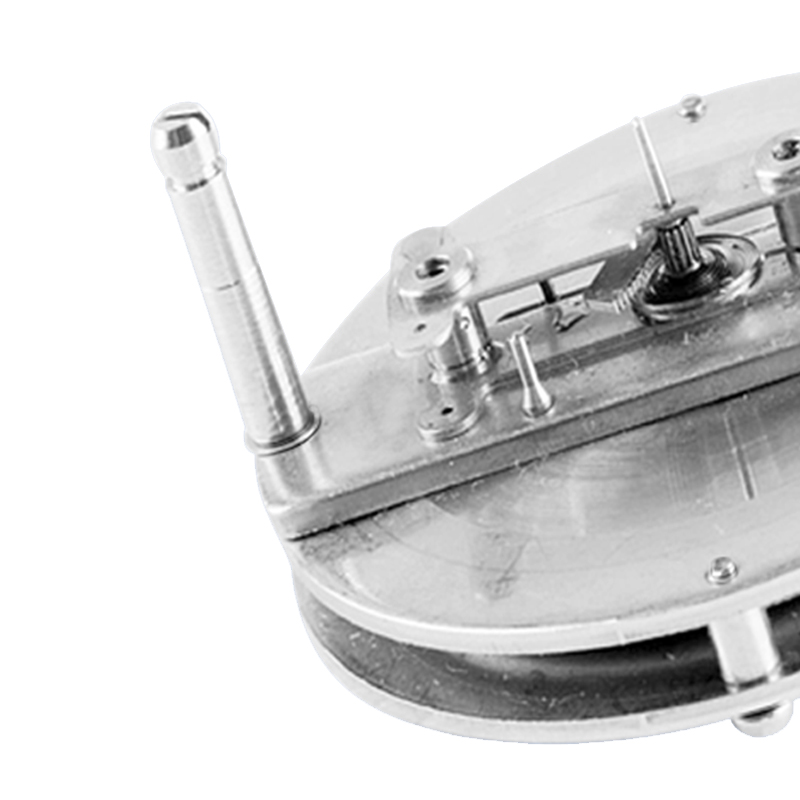

A diaphragm pressure gauge operates on the principle of deflection. When pressure is applied to the gauge, the diaphragm—typically made from materials such as stainless steel or brass—deflects in response to the pressure change. This deflection is then converted into a readable measurement via a mechanical linkage that moves the pointer on the dial face. The design of diaphragm gauges makes them particularly suitable for measuring low to moderate pressure ranges, ensuring accuracy and reliability in various industrial environments.

Key Applications

Diaphragm pressure gauges are widely used across different sectors, including

1. Oil and Gas Industry These gauges are instrumental in monitoring pipeline pressures, ensuring safety and preventing leaks. 2. Chemical Processing In chemical plants, diaphragm gauges provide crucial readings for monitoring the pressure of reactive substances, helping to maintain safe operational conditions.

3. Water and Wastewater Management Here, they are used to monitor pressures in water treatment plants, aiding in the control of flow and filtration processes.

4. Pharmaceuticals Given the stringent regulations within this industry, diaphragm gauges are critical in maintaining the standards required for drug production.

diaphragm pressure gauge wika factory

WIKA's Commitment to Quality

WIKA has built a reputation for delivering high-quality instrumentation, including diaphragm pressure gauges. The company emphasizes several key factors that contribute to their excellence in manufacturing

- Innovative Technology WIKA leverages the latest technology and engineering practices to design gauges that not only meet but exceed industry standards. Their diaphragm gauges feature robust designs that ensure accurate readings even in challenging conditions.

- Customization Options Understanding that different applications have unique requirements, WIKA offers customizable solutions. This includes variations in materials, pressure ranges, and connection types, enabling customers to find a gauge that suits their specific needs.

- Rigorous Testing WIKA places a strong focus on quality assurance. All their products undergo rigorous testing to ensure reliability and accuracy. This includes pressure tests, calibration, and environmental testing, guaranteeing that each gauge functions optimally in its intended application.

- Global Presence and Expertise With a comprehensive network of subsidiaries and representatives worldwide, WIKA is able to provide localized support and expertise. This global reach ensures that customers can access WIKA products and services, regardless of their geographical location.

The Future of Diaphragm Pressure Gauges

As industries continue to evolve, so too do the demands placed on pressure measurement instruments. The advancement of smart technologies and Industry 4.0 principles are shaping the future of instrumentation. In response, WIKA is investing in digital solutions that integrate diaphragm pressure gauges with process control systems. This allows for real-time monitoring and data analytics, facilitating enhanced decision-making capabilities for operators.

Conclusion

Diaphragm pressure gauges, particularly those manufactured by WIKA, represent an essential component in the toolkit of modern industry professionals. With their reliability, precision, and a commitment to innovation, WIKA’s diaphragm pressure gauges are poised to meet the demands of diverse applications while ensuring safety and efficiency in industrial operations. As technology evolves, WIKA continues to lead the way, proving that quality and performance can go hand in hand in the instrumentation industry.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025