Nov . 21, 2024 06:32 Back to list

diaphragm pressure gauge suppliers

Understanding Diaphragm Pressure Gauges and Their Suppliers

Diaphragm pressure gauges are critical instruments used across various industries to measure the pressure of liquids and gases. These gauges rely on the elastic properties of a diaphragm—a thin, flexible membrane that deflects under pressure. This deflection translates into a readable measurement, making diaphragm pressure gauges both accurate and reliable. Given their importance in ensuring operational safety and efficiency, the demand for quality diaphragm pressure gauge suppliers has increased substantially.

How Diaphragm Pressure Gauges Work

The fundamental principle behind diaphragm pressure gauges involves the deformation of the diaphragm when subjected to pressure. When pressure is applied, the diaphragm bends, causing a displacement that is linked to a pointer or digital readout, indicating the pressure value on the gauge face or display. This design allows for high accuracy and the ability to measure not only static but also dynamic pressures.

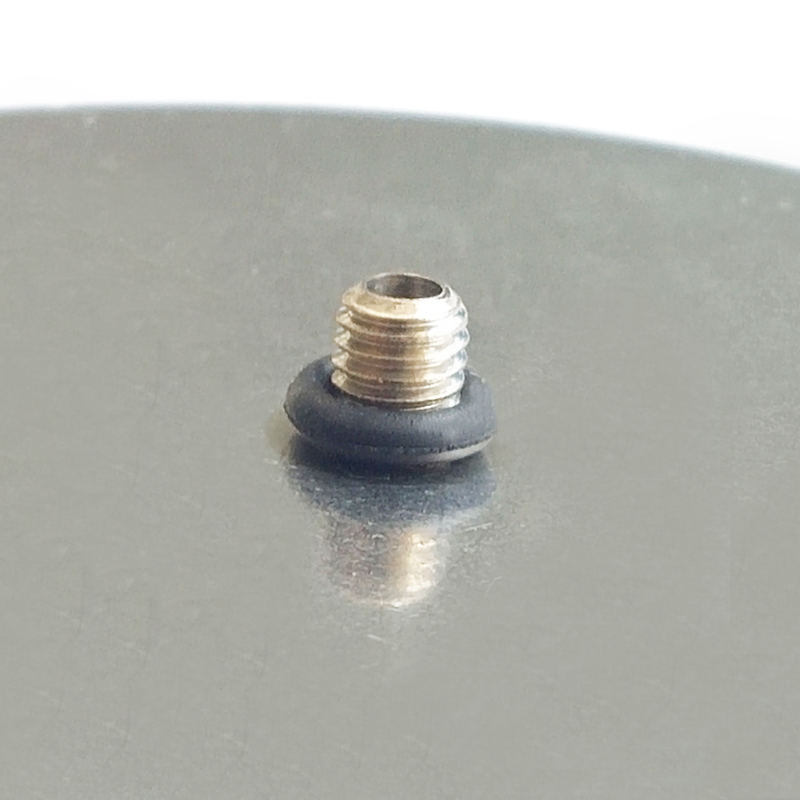

Diaphragm gauges are particularly advantageous for applications where the measured medium may be viscous, corrosive, or contain solid particles, as they can be designed with special materials and protective features to enhance durability and performance. Common materials used in the diaphragm include stainless steel, polymer composites, and other alloys that resist corrosion and wear.

Key Considerations When Choosing a Supplier

When searching for diaphragm pressure gauge suppliers, there are several critical factors to consider

1. Quality and Reliability Ensure that the supplier adheres to industry standards and regulations, such as ISO certifications. High-quality gauges are essential to maintain accuracy and longevity, which directly impacts operational efficiency.

diaphragm pressure gauge suppliers

2. Product Range A diverse product range allows companies to find the right gauge for their specific needs. Suppliers should offer various types of diaphragm gauges, including those suited for different pressure ranges, viscosities, and temperature conditions.

3. Technical Support Reliable suppliers provide ample technical support during pre-purchase, installation, and maintenance. This includes understanding gauge specifications, installation guidelines, and troubleshooting assistance.

4. Customization Options Different industries and applications may require specific features or customizations. A good supplier should offer customization options to meet these unique requirements.

5. Reputation Research the supplier’s reputation in the industry. Online reviews, case studies, and client testimonials can provide insights into their reliability and the performance of their products.

6. Pricing and Value While price is an important consideration, it shouldn’t be the sole factor. Look for suppliers who offer a good balance of quality and cost-effectiveness, ensuring that you receive the best value for your investment.

Conclusion

Diaphragm pressure gauges are indispensable tools in various industrial applications, from chemical processing to water treatment and beyond. Selecting the right supplier is crucial in ensuring that you receive a product that meets your needs for accuracy, durability, and reliability. By considering key factors such as quality, support, and customization options, industries can partner with suppliers that help maintain operational integrity and improve overall efficiency. As the demand for these instruments continues to grow, collaboration with reputable suppliers will remain essential in navigating the complexities of pressure measurement.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025