Dec . 05, 2024 17:17 Back to list

Understanding the Benefits of Diaphragm Pressure Gauges in Various Applications

Understanding Diaphragm Pressure Gauges Service and Maintenance

Diaphragm pressure gauges are essential instruments in industrial and laboratory settings, designed to measure and monitor pressure levels in various systems. Using a flexible diaphragm that deflects under pressure, these gauges provide accurate readings and are popular in applications involving corrosive or viscous fluids. To ensure their long-term reliability and accuracy, proper service and maintenance are crucial. This article delves into the significance of diaphragm pressure gauges, their applications, and essential maintenance practices.

The Role of Diaphragm Pressure Gauges

Diaphragm pressure gauges are widely used across different sectors, including oil and gas, chemical manufacturing, water treatment, and food processing. Their design allows them to measure pressure within a sealed environment while preventing the internal mechanism from being damaged by harsh substances. The diaphragm, typically made from materials resistant to corrosion such as stainless steel or specially coated alloys, responds to changes in pressure, converting mechanical deformation into a readable output.

One of the primary advantages of diaphragm pressure gauges is their ability to handle pulsating and fluctuating pressure, making them ideal for dynamic environments. They provide reliable measurements even in the presence of erratic flows, which is crucial for maintaining safety and efficiency in industrial processes.

Importance of Regular Maintenance

Maintaining diaphragm pressure gauges is vital for several reasons. First and foremost, regular service ensures accurate readings, which are essential for safety and operational efficiency. A malfunctioning gauge can lead to incorrect pressure readings, potentially resulting in equipment failure, hazardous situations, or inefficient processes.

Moreover, routine maintenance can extend the lifespan of the gauge. Without proper care, the diaphragm can become worn or damaged, affecting its performance. Regular inspections can identify wear and tear before they escalate into more significant issues that may necessitate costly repairs or replacements.

Key Maintenance Practices

diaphragm pressure gauges service

To keep diaphragm pressure gauges in optimal condition, various maintenance practices should be followed

1. Routine Inspection Regularly inspect the gauge for signs of wear, corrosion, or leaks. Look for any changes in the readings, which could indicate that the diaphragm is damaged or that there are obstructions in the system.

2. Calibration Regular calibration is essential for ensuring accuracy. Depending on the application and environmental conditions, gauges may need to be calibrated more frequently. This process involves comparing the gauge reading to a known standard and adjusting it as necessary.

3. Cleaning Keep the gauge and its connection points free from contaminants. Depending on the application, debris or buildup can affect performance. Use suitable cleaning agents that won’t harm the materials of the gauge.

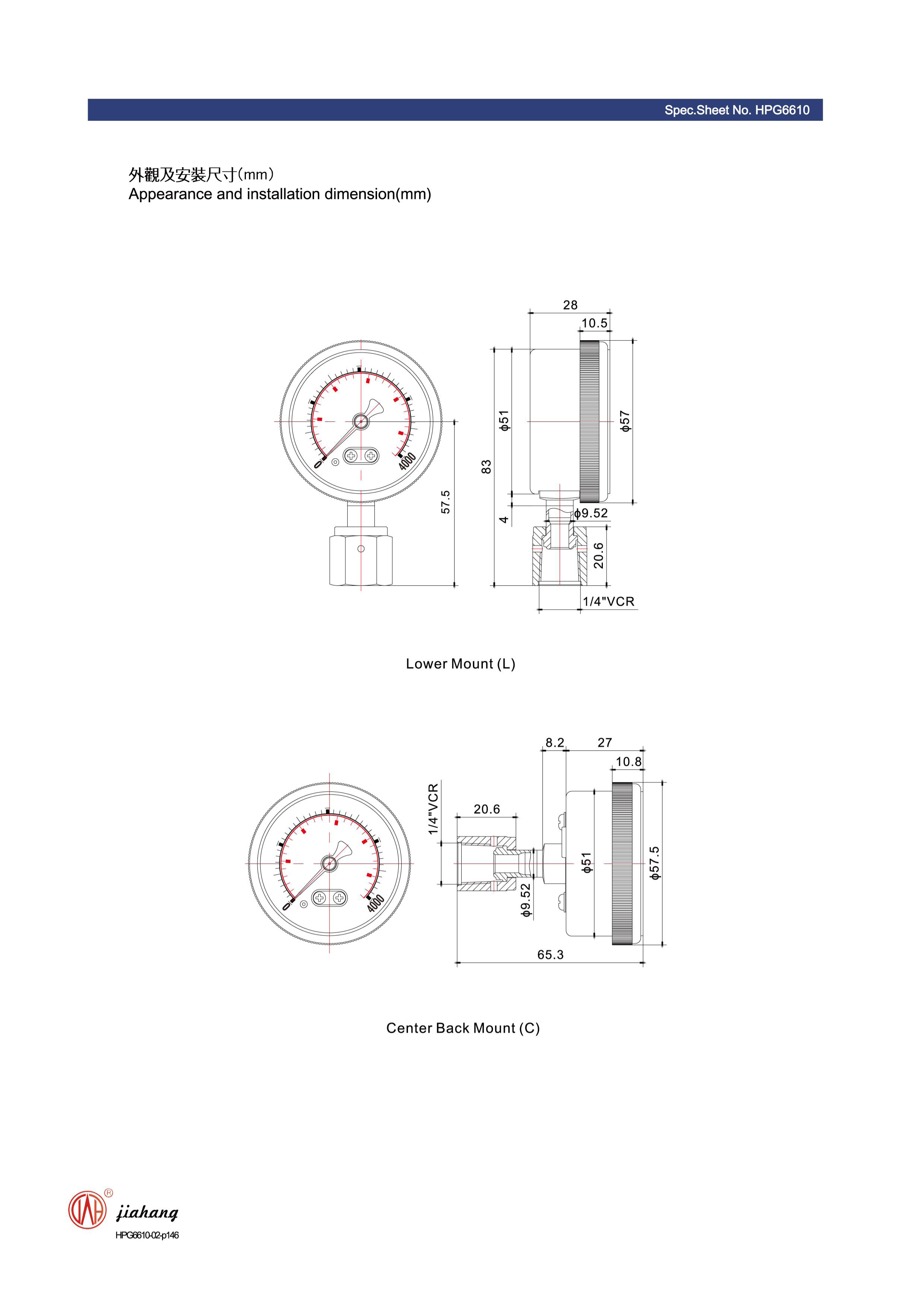

4. Proper Installation Ensure that the diaphragm pressure gauge is installed correctly to avoid unnecessary stress on the diaphragm. Follow the manufacturer’s guidelines regarding mounting orientations and torque specifications.

5. Environmental Considerations Protect the gauges from extreme temperatures, vibrations, and corrosive conditions that can accelerate wear. When possible, use protective enclosures or select gauges rated for specific environmental conditions.

6. Documentation Maintain thorough records of maintenance activities, inspections, and calibrations. This documentation can help identify trends over time and provide insights into when a gauge might need replacement.

Conclusion

Diaphragm pressure gauges play a crucial role in various industries by providing accurate and reliable pressure measurements. Regular service and maintenance are pivotal to ensuring their longevity and performance. By implementing routine inspections, calibrations, and preventive care, organizations can enhance the reliability of their systems and safeguard against potential failures. In an ever-evolving industrial landscape, investing in the maintenance of diaphragm pressure gauges is a proactive step toward operational excellence and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025