Sep . 22, 2024 10:52 Back to list

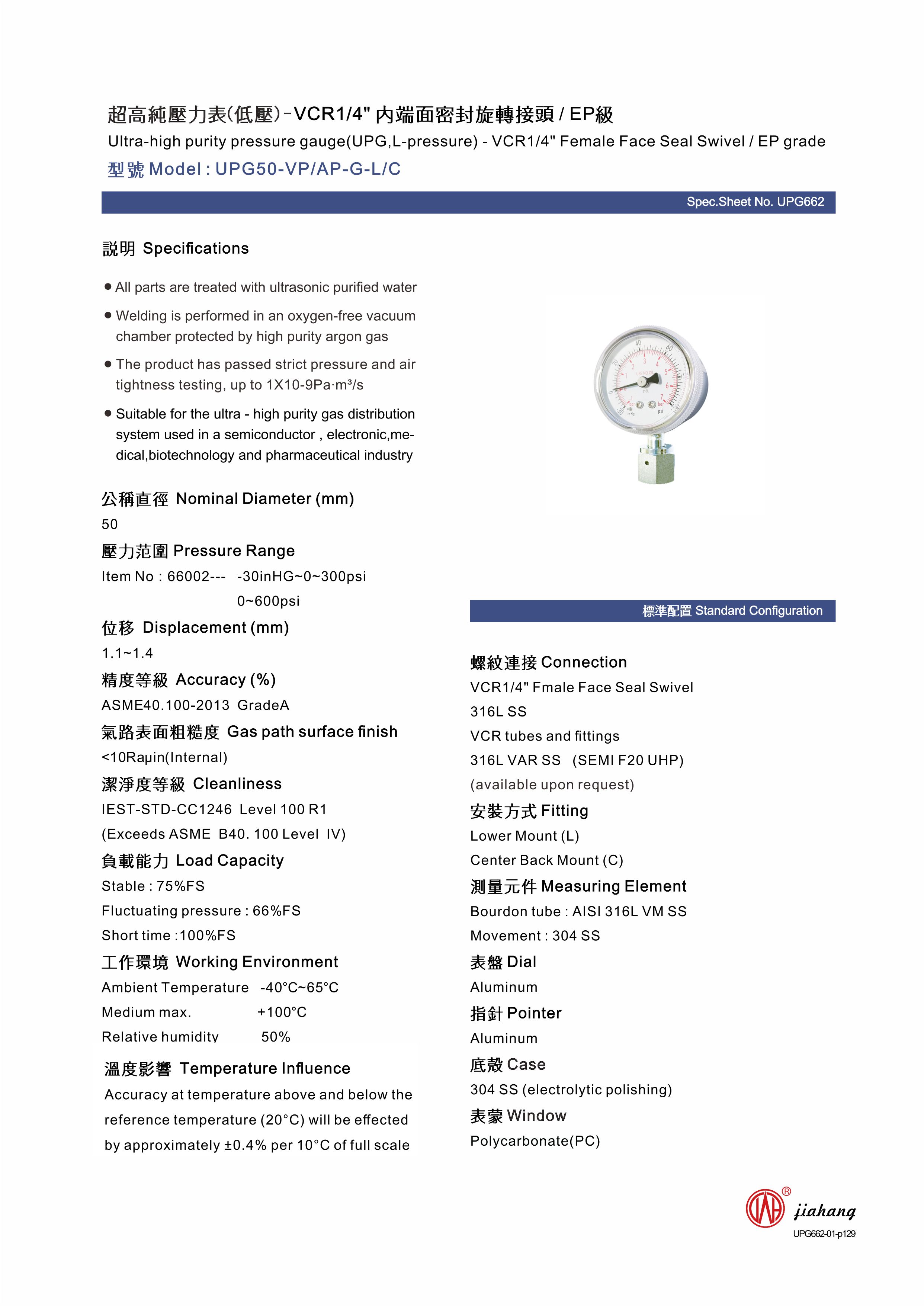

diaphragm pressure gauge product

Understanding Diaphragm Pressure Gauges An Essential Tool in Measurement Technology

Diaphragm pressure gauges are widely used instruments in various industries for measuring pressure in gases and liquids. Their design and functionality make them a reliable choice for applications that require precise and accurate readings. These gauges operate on the fundamental principle of using a flexible diaphragm, which responds to pressure changes in the environment, translating them into readable measurements.

Understanding Diaphragm Pressure Gauges An Essential Tool in Measurement Technology

Diaphragm pressure gauges are also praised for their robustness and durability. Unlike traditional Bourdon tube gauges, diaphragm gauges are less prone to damage from vibrations and pulsations, making them ideal for harsh environments and fluctuating pressures. Additionally, their sealed construction protects the internal components from dust and moisture, enhancing longevity and reliability, which is crucial for maintaining operational efficiency in demanding applications.

diaphragm pressure gauge product

The versatility of diaphragm pressure gauges allows them to be used in a wide array of industries, including oil and gas, pharmaceuticals, food and beverage, and water treatment. In each of these fields, maintaining precise pressure levels is vital for safety and quality control. For example, in the food and beverage industry, accurate pressure measurement is essential for processes like carbonation and bottling, ensuring that products meet safety standards and consumer expectations.

Moreover, advancements in technology have led to the development of digital diaphragm pressure gauges, which offer enhanced features such as data logging, remote monitoring, and integration with process control systems. These innovations enable industries to optimize performance and maintain rigorous standards in pressure management.

In summary, diaphragm pressure gauges stand out as crucial instruments in modern measurement technology. Their ability to provide accurate, reliable pressure readings in various conditions makes them indispensable in numerous industrial applications. As technology advances, the evolution of diaphragm gauges will continue to enhance their functionality, ensuring that they meet the ever-increasing demands of industries worldwide.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025