Nov . 15, 2024 17:14 Back to list

diaphragm contact pressure gauge

Understanding Diaphragm Contact Pressure Gauges

Diaphragm contact pressure gauges are crucial instruments used in various industrial applications to measure and monitor pressure. These gauges operate based on the principle of diaphragm deformation in response to pressure changes. This article examines the fundamentals of diaphragm contact pressure gauges, their working mechanism, applications, and advantages.

Fundamental Principles

At the core of a diaphragm contact pressure gauge is a thin, flexible membrane known as a diaphragm. This diaphragm is typically made of materials like stainless steel or rubber, selected for their ability to withstand harsh environments and pressures. When pressure is applied, the diaphragm flexes, causing a mechanical movement. This movement is then translated into a readable measurement on the gauge.

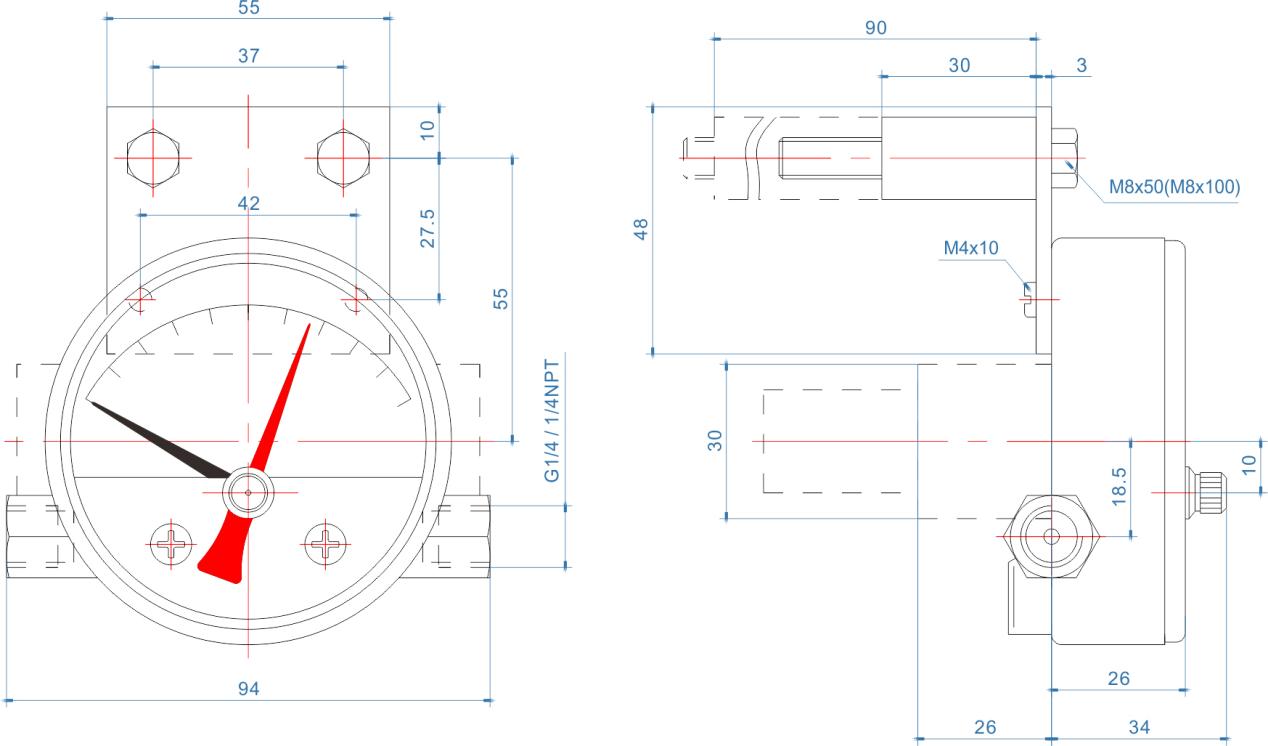

The main components of a diaphragm pressure gauge include the diaphragm itself, a pressure chamber, a mechanism for translating the diaphragm’s movement into a readable format (usually a dial or digital readout), and electrical or mechanical contacts that can trigger an alarm or switch when a specific pressure is reached.

Working Mechanism

As pressure acts on one side of the diaphragm, it flexes away from the pressure source. This flexing movement is proportional to the amount of pressure exerted. The sensor components then convert this mechanical deflection into an electrical signal or direct mechanical movement for the readout. In many models, limit switches are used, which activate when pressure exceeds predetermined levels, providing system safety alerts.

With advancements in technology, modern diaphragm contact pressure gauges can also come equipped with digital displays, data logging capabilities, and remote monitoring functions, enhancing their usability in complex systems.

diaphragm contact pressure gauge

Applications

Diaphragm contact pressure gauges find their applications in a multitude of industries. They are extensively used in oil and gas, chemical manufacturing, power generation, water treatment, and HVAC systems. Particularly, in applications where pressure monitoring is critical for process safety and efficiency, these gauges provide an invaluable service.

For instance, in chemical processing plants, maintaining precise pressure levels is vital to ensure safe operation. The diaphragm gauge can alert operators to pressure fluctuations, reducing the risk of overpressure situations that could lead to dangerous incidents.

Advantages

One of the primary advantages of diaphragm contact pressure gauges is their ability to measure pressures accurately while being resistant to temperature fluctuations, corrosive materials, and high-stress environments. Their mechanical design means they require little maintenance, unlike electronic sensors that may be affected by humidity or electromagnetic interference.

Furthermore, diaphragm gauges can be designed to accommodate a range of pressure levels, making them versatile for various applications. The durability and reliability of diaphragm gauges ensure long service life, providing an economical solution for continuous pressure monitoring.

Conclusion

In summary, diaphragm contact pressure gauges are integral tools in the realm of industrial pressure measurement. Their unique working principles, combined with their robust construction and versatile applications, make them indispensable in maintaining safety and efficiency across various sectors. As technology progresses, the evolution of these gauges promises even greater precision and functionality, ensuring they remain at the forefront of pressure measurement solutions.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025