Oct . 21, 2024 23:45 Back to list

diaphragm capsule pressure gauge product

Understanding Diaphragm Capsule Pressure Gauges

Pressure measurement is a critical aspect in various industries, including oil and gas, chemical processing, and food production. Among the numerous types of pressure measuring instruments, diaphragm capsule pressure gauges have gained popularity due to their reliability and precision in measuring low pressures. This article explores the design, functionality, advantages, and applications of diaphragm capsule pressure gauges, providing a comprehensive overview of this essential instrument.

Design and Functionality

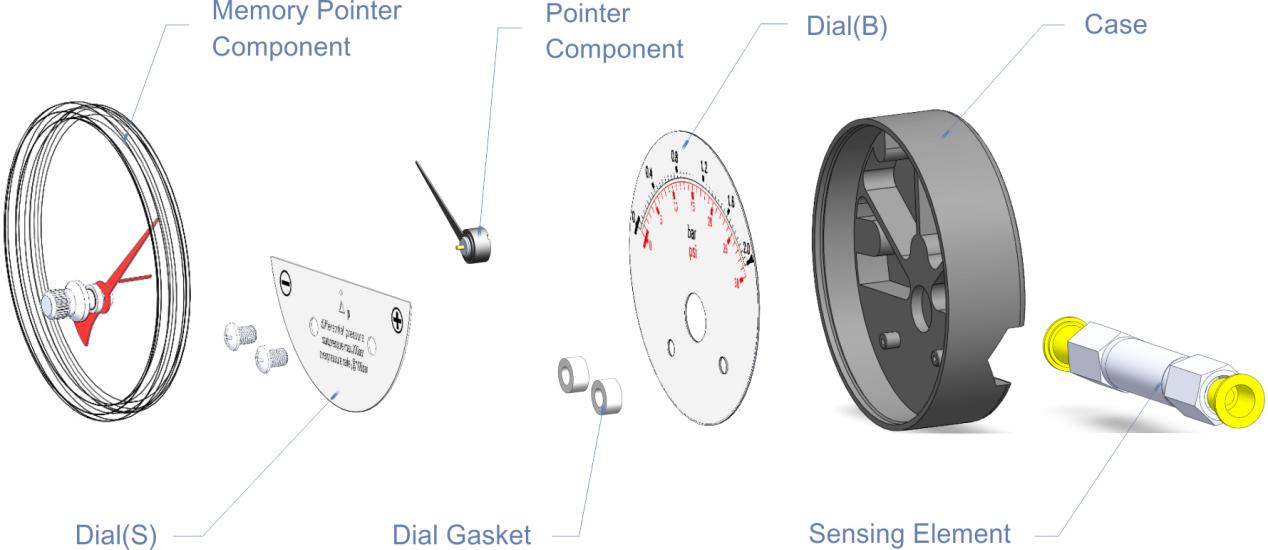

A diaphragm capsule pressure gauge typically consists of two metal diaphragms separated by a vacuum or gas-filled space, forming a capsule shape. When there is a pressure difference between the two sides, the diaphragms flex. This movement is then transmitted through a mechanical link to a pointer or digital display, providing a reading of the pressure. The design allows for high sensitivity and the ability to accurately measure low-pressure ranges, often as low as 1 mbar.

The materials used in the construction of diaphragm capsule gauges are crucial for their performance. Common materials include stainless steel, brass, and different alloys, which offer resistance to corrosion and wear. Moreover, various diaphragm materials like rubber and PTFE ensure compatibility with diverse media, enhancing their versatility in different settings.

Advantages

1. High Sensitivity Diaphragm capsule pressure gauges are capable of measuring very low pressures with high accuracy, making them ideal for sensitive applications. 2. Robust Construction The durable materials used in these gauges ensure longevity and reliability, even in harsh environments.

3. Minimal Maintenance Once installed, diaphragm capsule gauges require very little maintenance and are less prone to wear and tear compared to other types of gauges.

diaphragm capsule pressure gauge product

4. Versatility They can be used for various media types, including gases, liquids, and even aggressive fluids, depending on the materials used in the construction.

5. Compact Design The small size and lightweight nature of diaphragm capsule gauges make them easy to install and integrate into both new and existing systems.

Applications

Diaphragm capsule pressure gauges find application in numerous fields. In the food and beverage industry, they are used to monitor the pressure in processes where hygiene is critical. In the pharmaceutical sector, these gauges help in ensuring the precise delivery of gases and fluids during the manufacturing process.

Additionally, they are employed in HVAC systems to measure airflow and pressure drops, ensuring optimal performance and energy efficiency. Other applications include environmental monitoring, automotive systems, and pneumatic systems, where accurate pressure measurement is crucial for safety and efficiency.

Conclusion

Diaphragm capsule pressure gauges are indispensable tools in modern industry, offering precision, durability, and versatility in measuring low pressures. Their robust design, minimal maintenance needs, and adaptability make them suitable for a wide range of applications. As industries continue to evolve, the importance of accurate pressure measurement cannot be overstated, and diaphragm capsule gauges are poised to remain at the forefront of this essential function. Whether in the lab, on the production floor, or in field applications, these gauges play a crucial role in ensuring safe and efficient operations across various sectors.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025