Sep . 21, 2024 17:43 Back to list

customized differential pressure gauge products

Customized Differential Pressure Gauge Products Tailoring Precision Measurement Solutions

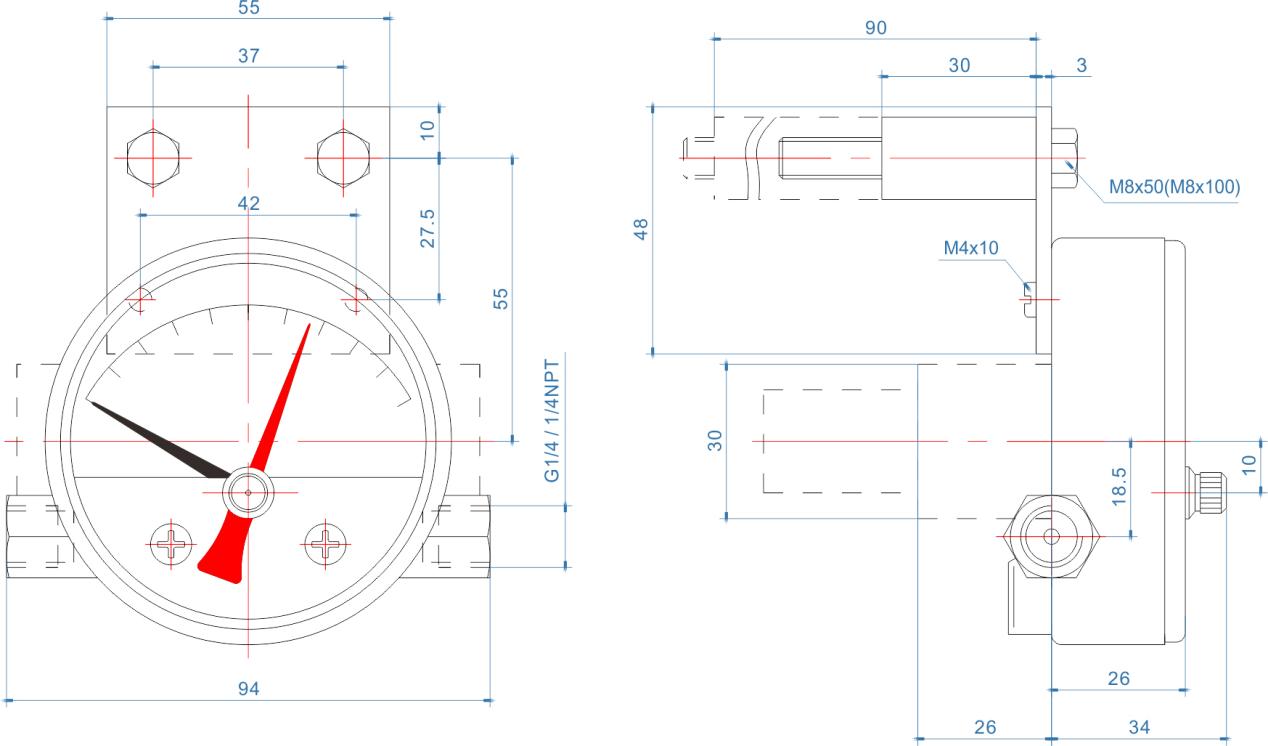

In a world where precision and adaptability are paramount, customized differential pressure gauge products emerge as vital tools for various industrial applications. These sophisticated instruments are designed to measure the pressure difference between two points in a system, providing critical data for processes where pressure variations can impact performance, safety, and efficiency.

Differential pressure gauges have numerous applications, ranging from HVAC systems and liquid filtration to chemical processing and oil and gas industries. The ability to track pressure differentials ensures that systems operate within their optimal parameters, preventing costly downtimes and equipment failures. However, not all applications are the same; different industries present unique challenges that standard gauges may not adequately address. This is where customized solutions shine.

Customization in differential pressure gauges can manifest in various aspects, including size, range, materials, and display options. For instance, a facility dealing with highly corrosive materials may require gauges built from specialized alloys resistant to chemical degradation. In contrast, a clean room environment may need gauges that prevent contamination and are easy to sanitize.

One of the key advantages of bespoke differential pressure gauges is their tailored measurement range. Standard products may not fit the specific requirements of every application. By customizing the range, companies can achieve greater accuracy and reliability in their readings. This is particularly critical in sectors like pharmaceuticals, where precise pressure measurement is essential for compliance with stringent safety regulations.

customized differential pressure gauge products

Beyond physical characteristics, customization also extends to the integration of advanced features. Digital interfaces, remote monitoring capabilities, and data logging options can be added to gauges to enhance functionality. Such features enable real-time analysis and greater visibility over system performance, empowering operators to make informed decisions swiftly.

Moreover, the development of customized differential pressure gauges is aided by modern manufacturing techniques, including 3D printing and advanced sensor technologies. These innovations allow for rapid prototyping and production of specialized gauges, thus reducing lead times and costs associated with custom orders. Businesses can benefit from quick turnaround times, enabling them to respond to evolving demands in their operational environments.

Implementing customized differential pressure gauge solutions not only boosts operational efficiency but also fosters a culture of innovation and continuous improvement. Companies are increasingly recognizing the importance of tailored measurement solutions as they strive to optimize processes and enhance overall performance.

In conclusion, customized differential pressure gauge products are essential tools that cater to the diverse needs of various industries. The ability to adapt these instruments to specific applications enhances accuracy, reliability, and overall system efficiency. As industries continue to evolve, the demand for customized measurement solutions will only increase, underscoring the crucial role that differential pressure gauges play in supporting modern operations. Whether for regulatory compliance or operational excellence, investing in customized gauges can prove to be a game-changer in achieving long-term success.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025