Dec . 18, 2024 17:35 Back to list

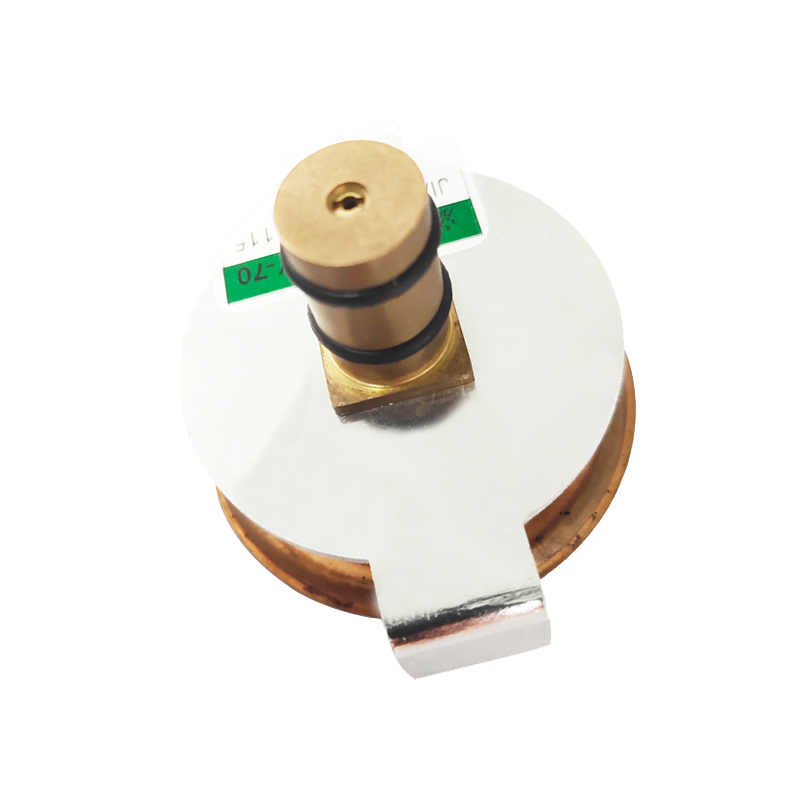

customized differential pressure gauge products

Customized Differential Pressure Gauge Products Tailored Solutions for Accurate Measurements

In today's rapidly evolving industrial landscape, precision measurement is paramount for maintaining operational efficiency and ensuring safety standards. Differential pressure gauges play a crucial role in various applications, ranging from HVAC systems to cleanrooms, and even in the oil and gas sector. Customized differential pressure gauge products are becoming increasingly essential for professionals seeking tailor-made solutions that meet their specific needs.

Understanding Differential Pressure Gauges

Differential pressure gauges are instruments designed to measure the difference in pressure between two points within a system. This measurement is pivotal in various applications, such as monitoring airflow in ventilation systems, determining filter conditions, measuring liquid levels, and ensuring process control. These instruments are integral to maintaining optimal performance, system integrity, and compliance with industrial regulations.

The standard differential pressure gauge often features a dial gauge with one or more pressure connections for measuring pressure at specific points. However, not all applications are created equal, and there is no one-size-fits-all solution when it comes to pressure measurement. This is where customized differential pressure gauges come into play.

Benefits of Customized Solutions

1. Precision and Accuracy Customized differential pressure gauges are designed to meet specific operational requirements. Whether it's specific pressure ranges, unique fitting sizes, or specialized materials to withstand corrosive environments, these gauges ensure accurate readings tailored to the application.

2. Enhanced Durability Different industries have unique environmental challenges, including extreme temperatures, humidity, or exposure to harsh chemicals. Customized solutions can be manufactured to withstand these conditions, using materials such as stainless steel, plastics, or specialized coatings that prolong the lifespan of the instrument.

3. Integration and Compatibility Customized gauges can be engineered to seamlessly integrate into existing systems. By considering the specific layout and requirements of machinery or infrastructure, manufacturers can develop differential pressure gauges that are easier to install and operate, improving overall system performance.

4. Versatility in Design Customized products allow for a wide variety of designs, dimensions, and fittings. This versatility means that operators can find solutions that fit visually and technologically into existing setups, ensuring reliability and aesthetics.

customized differential pressure gauge products

5. Improved Monitoring and Control In industries where maintaining optimal conditions is critical, customized differential pressure gauges can be designed to include advanced features such as digital displays, alarms, and data logging capabilities. This modernization enables better monitoring and control, minimizing downtime and increasing productivity.

Applications of Customized Differential Pressure Gauges

Customized differential pressure gauges find applications across a broad spectrum of industries

- HVAC Systems In heating, ventilation, and air conditioning systems, these gauges help monitor airflow, ensuring that systems operate efficiently. Customized designs can cater to specific duct sizes and airflow requirements.

- Pharmaceuticals and Biotechnology Within sensitive environments such as cleanrooms, customized differential pressure gauges can help maintain the required sterile conditions by monitoring air pressure differentials that prevent contamination.

- Oil and Gas Customized gauges can withstand high pressures and extreme environments, allowing for accurate monitoring throughout drilling and extraction processes, providing crucial data that enhances safety and efficiency.

- Water and Wastewater Treatment These gauges are essential for monitoring pressure across various stages of water management, ensuring that systems remain operational and efficient in delivering safe water supplies.

Conclusion

Customized differential pressure gauge products represent a vital component in the quest for precision and reliability in measurement. In an industrial landscape marked by the need for efficiency and safety, investing in customized solutions ensures that specific operational needs are met, ultimately enabling organizations to enhance performance, reduce risk, and maintain compliance. With the right differential pressure gauge tailored to individual requirements, businesses can confidently navigate the complexities of their respective sectors, making meticulous measurements that drive success. Whether in a laboratory, an industrial site, or a commercial building, customized solutions hold the key to achieving optimal performance and operational excellence.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025