Sep . 28, 2024 17:58 Back to list

Customized Differential Pressure Gauge Solutions for Industrial Applications and Enhanced Performance

Customized Differential Pressure Gauge Enhancing Measurement Precision

In various industrial applications, accurate measurement of pressure differences is critical to ensuring operational efficiency and safety. Differential pressure gauges play a vital role in a multitude of sectors, including oil and gas, pharmaceuticals, biotechnology, and HVAC systems. With the increasing demand for customized solutions, tailored differential pressure gauges are becoming essential tools for meeting specific operational requirements.

Understanding Differential Pressure Gauges

A differential pressure gauge measures the difference between two pressure points. It provides vital information on the flow rates in pipelines, the condition of filters, or the static pressure in systems. Traditional differential pressure gauges have served many industries well; however, advancements in technology and the need for higher accuracy have prompted the development of customized solutions.

The Need for Customization

The diverse applications of differential pressure gauges require unique design specifications and features. A one-size-fits-all approach is often insufficient due to variations in media type, environmental conditions, and measurement ranges. Businesses are faced with unique challenges, such as extreme temperatures, corrosive environments, or specific process requirements. Hence, customized differential pressure gauges address these challenges effectively.

A customized gauge might include specific materials resistant to chemical corrosion, specific pressure ranges designed to accommodate high or low-pressure systems, or even advanced digital displays for better readability. Customization allows manufacturers to ensure that each gauge performs optimally within the parameters of its specific application.

Benefits of Customized Differential Pressure Gauges

1. Precision and Accuracy Customized gauges are designed with the specific needs of the application in mind. They can enhance the accuracy of measurements and ensure that the data collected reflects true pressure differentials. This is crucial for processes that require tight tolerances.

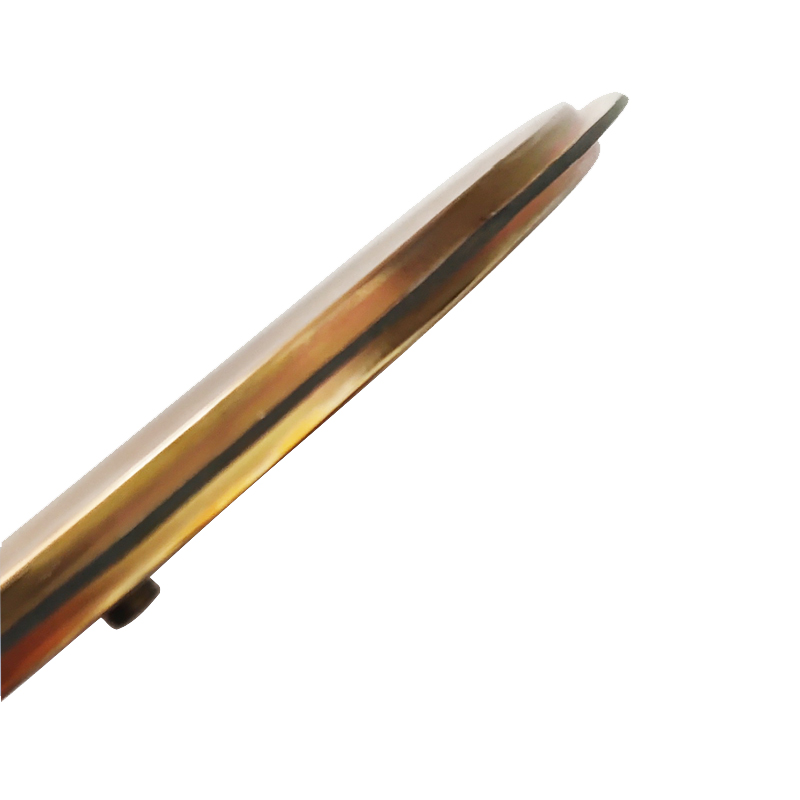

customized differential pressure gauge jah

2. Durability and Longevity By selecting appropriate materials and components based on the operating environment, customized gauges reduce wear and tear. This leads to lower maintenance costs and a longer service life, which is particularly important in challenging environments.

3. Improved Process Efficiency Accurate differential pressure readings allow for better process monitoring and control. This can result in higher productivity, reduced energy consumption, and less downtime due to equipment failure or unscheduled maintenance.

4. Compliance and Safety Many industries are governed by strict regulations regarding pressure measurement and safety standards. Customized gauges can be designed to meet specific regulatory requirements, ensuring compliance while enhancing safety in operations.

5. Enhanced Data Collection Many customized differential pressure gauges now integrate advanced technology such as digital displays, automation compatibility, and data logging features. This allows for real-time monitoring and easier data collection, which can drive informed decision-making.

Choosing the Right Manufacturer

When opting for customized differential pressure gauges, selecting the right manufacturer is crucial. A reputable manufacturer will conduct a comprehensive needs assessment to understand the specifics of the application. They should offer engineering support, a variety of customization options, and rigorous testing practices to ensure that the final product meets all necessary standards.

Additionally, manufacturers should provide detailed documentation regarding the gauge’s performance, calibration certificates, and compliance with industry standards. A strong post-sale support framework is also vital to address any issues that may arise during the product's lifecycle.

Conclusion

Customized differential pressure gauges are essential tools for industries that demand high precision and reliability in pressure measurement. By focusing on the unique needs of different applications, manufacturers can deliver tailored solutions that enhance operational efficiency, comply with safety standards, and ultimately drive success in an increasingly competitive landscape. As industries continue to evolve, the role of customized measurement solutions will undoubtedly expand, paving the way for innovations that further optimize processes and ensure safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025