Dec . 04, 2024 15:36 Back to list

Custom Flanged Diaphragm Pressure Gauge for Precise Pressure Measurement Solutions

Understanding Custom Flanged Diaphragm Pressure Gauges

In industrial applications, precise measurements of pressure are crucial for maintaining safety and efficiency. Among the various types of pressure measurement devices, the custom flanged diaphragm pressure gauge stands out due to its unique design and versatility. This article delves into the features, advantages, and applications of these gauges, highlighting their importance in modern industrial settings.

What is a Flanged Diaphragm Pressure Gauge?

A flanged diaphragm pressure gauge is a specialized instrument designed to measure the pressure of gases or liquids in tanks, pipelines, and various other systems. The core component of this gauge is the diaphragm, a flexible membrane that deflects in response to pressure changes. Typically crafted from durable materials such as stainless steel or other alloys, the diaphragm ensures high sensitivity and resistance to corrosion and fatigue.

The “flanged” designation refers to the flange—an elevated border around the diaphragm that allows for easy installation and secure connection to fittings. This design feature not only simplifies the installation process but also ensures a tight seal, minimizing the risk of leaks and ensuring accurate readings.

The Importance of Customization

One of the standout aspects of flanged diaphragm pressure gauges is their customizability. Industries often face unique challenges that require tailored solutions. Custom gauges can be designed to meet specific pressure ranges, temperature tolerances, and materials compatible with the fluids being measured. For instance, a gauge utilized in the oil industry might require special coatings or materials to withstand corrosive substances, while a food processing application calls for hygienic and FDA-compliant components.

Key Features and Advantages

1. Accuracy and Precision The diaphragm's responsive nature allows for highly accurate pressure readings. By minimizing mechanical complexity and leveraging the direct response of the diaphragm, these gauges can deliver precise performance even in fluctuating conditions.

2. Durability Custom flanged diaphragm pressure gauges are built strong, often designed to endure extreme environments. Their robust construction provides long-lasting performance, reducing the need for frequent replacements.

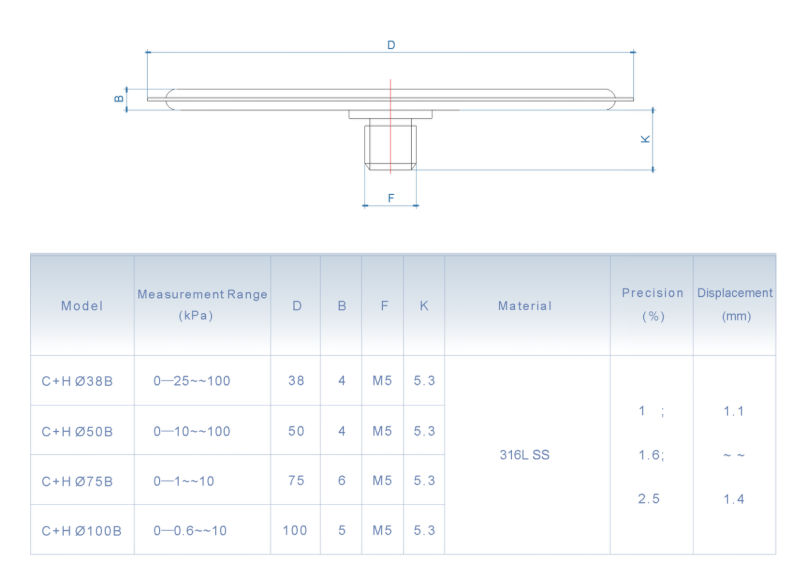

custom flanged diaphragm pressure gauge

3. Wide Pressure Range These gauges can be tailored to handle a variety of pressure ranges, making them suitable for both high and low-pressure applications. This adaptability is valuable across diverse sectors, from manufacturing to chemical processing.

4. Ease of Integration The flanged design allows for straightforward installation, enabling seamless integration into existing systems. This ease of use can save valuable time during setup and reduce operational downtime.

5. Versatile Applications Custom flanged diaphragm pressure gauges are versatile instruments used in various sectors, including oil and gas, water treatment, pharmaceuticals, food and beverage, and manufacturing. Their ability to handle different materials and pressure conditions makes them an indispensable component in many industrial setups.

Applications Across Industries

1. Oil and Gas In this sector, pressure gauges are essential for monitoring the flow and pressure of fluids during extraction and processing. Custom configurations ensure that these gauges can withstand the harsh environments found in oil fields.

2. Water and Wastewater Management These gauges are critical in pipelines and treatment plants, helping to monitor pressure to maintain safe and efficient operations.

3. Pharmaceuticals In sterile environments, custom gauges help ensure that pressure levels meet stringent regulatory standards, critical for the safety and integrity of product manufacturing.

4. Food and Beverage Customization ensures that materials used in the gauge meet sanitary guidelines, crucial for ensuring product quality and safety.

Conclusion

Custom flanged diaphragm pressure gauges play a vital role in ensuring operational efficiency and safety across various industries. Their accurate, durable, and adaptable design make them ideal for measuring pressure in a wide array of applications, from oil and gas to pharmaceuticals. As industries continue to evolve, the need for reliable and precise pressure measurement solutions will only grow, and custom gauges will be at the forefront of these advancements. Embracing the benefits of custom flanged diaphragm pressure gauges can elevate operational capabilities, providing industries with the tools necessary to thrive in an ever-competitive landscape.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025