Oct . 21, 2024 20:40 Back to list

Custom Differential Pressure Gauge with Monitoring Features for Enhanced Performance Tracking

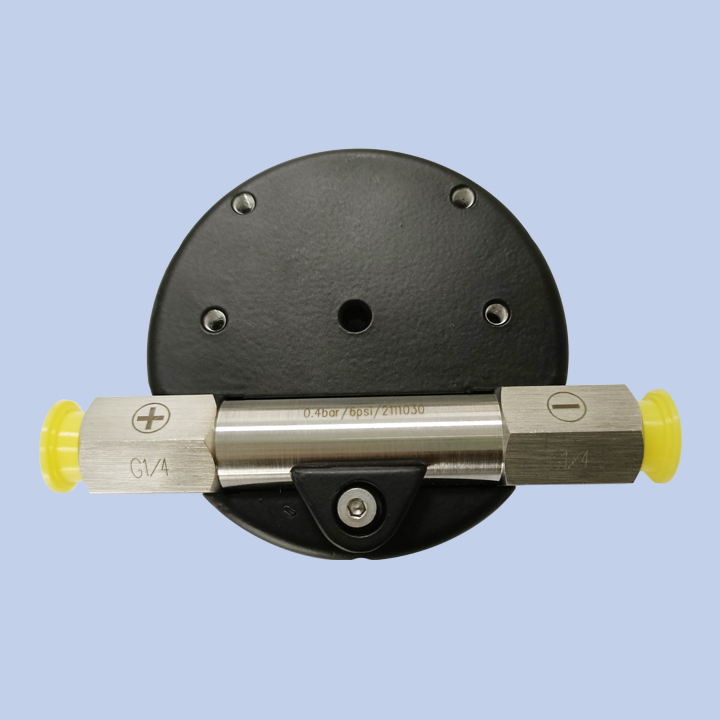

Custom Differential Pressure Gauge with Tattle Tale An Overview

In the world of industrial instrumentation, precision and reliability are paramount. Among the essential tools in this realm, differential pressure gauges play a crucial role, particularly in monitoring the pressure difference between two points in a system. These gauges are vital for ensuring efficient operation in various applications, from HVAC systems to filtration processes. However, the need for customization has emerged as industries seek solutions tailored to their specific requirements. Enter the custom differential pressure gauge with a tattle tale feature.

A differential pressure gauge measures the pressure difference between two points, enabling operators to assess system performance and detect any irregularities. The addition of a tattle tale function enhances the gauge's utility significantly. This feature acts as an indicator or a warning system that records peak pressures during a given period. If the pressure difference exceeds a certain threshold, the tattle tale designates this occurrence, allowing for timely intervention before any serious issues arise.

The custom aspect of such gauges caters to the unique needs of different industries. For instance, in the pharmaceutical sector, stringent regulations demand precise monitoring of air filtration systems. A custom differential pressure gauge can be designed to meet these regulations while integrating a tattle tale function, ensuring that operators are alerted to any deviations that could affect product quality. This level of customization not only aids in compliance but also enhances the overall efficiency of the process.

custom differential pressure gauge with tattle tale

Similarly, in oil and gas applications, maintaining the integrity of pipelines is critical. A custom differential pressure gauge equipped with a tattle tale allows operators to monitor pressure differentials closely, thereby identifying potential leaks or blockages. By providing real-time data, these gauges empower operators to take corrective actions swiftly, preventing costly downtime and ensuring safety.

The design of a custom differential pressure gauge with a tattle tale incorporates advanced technology and materials to enhance performance. For example, innovative sensor technology can be integrated to ensure accurate readings, while durable materials can be used to withstand harsh environmental conditions. Furthermore, the tattle tale feature can be designed with user-friendly interfaces, including digital displays that provide clear visual indicators of pressure status and alerts.

In addition to operational benefits, these gauges also contribute to achieving sustainability goals. By monitoring pressure differentials effectively, companies can optimize their processes, reducing energy consumption and waste. This aligns with the growing trend towards sustainability in industrial practices, where efficiency and environmental responsibility go hand in hand.

In conclusion, the custom differential pressure gauge with a tattle tale feature represents a significant advancement in industrial instrumentation. By offering tailored solutions that meet specific industry needs, these gauges enhance operational efficiency, ensure compliance, and contribute to safety and sustainability. As industries continue to evolve and require more sophisticated monitoring solutions, the demand for such custom instruments is expected to grow. Companies that invest in these advanced monitoring systems will likely enjoy a competitive edge, ultimately leading to greater reliability and success in their operations. The integration of technology and customization ensures that differential pressure gauges are not just tools of measurement but pivotal components in the overall management of industrial processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025