Sep . 28, 2024 00:15 Back to list

Custom Differential Pressure Gauge with Diaphragm Seal for Enhanced Performance and Accuracy

Understanding Custom Diaphragm Seal Differential Pressure Gauges

In various industrial applications, maintaining accurate pressure measurement is crucial for operational efficiency, safety, and equipment longevity. One such valuable instrument that plays a critical role in pressure measurement is the custom diaphragm seal differential pressure gauge. This specialized device combines the functionality of a differential pressure gauge with a diaphragm seal, making it suitable for a wide range of challenging environments.

Differential pressure gauges measure the difference in pressure between two points in a system, which is essential for monitoring processes such as filtering, flow measurement, and level control. However, in many applications, especially those involving corrosive, viscous, or high-purity fluids, the measuring element can be subjected to harsh conditions that could compromise accuracy and performance. This is where custom diaphragm seal systems come into play.

The diaphragm seal acts as a barrier between the pressure fluid and the gauge itself, protecting sensitive components from potential contamination, high temperatures, and abrasive materials. It consists of a flexible diaphragm that deforms in response to pressure changes, transmitting the force to the pressure sensing element without compromising the integrity of the gauge. This design not only prolongs the lifespan of the gauge but also ensures reliable measurements in adverse conditions.

custom diaphragm seal differential pressure gauge

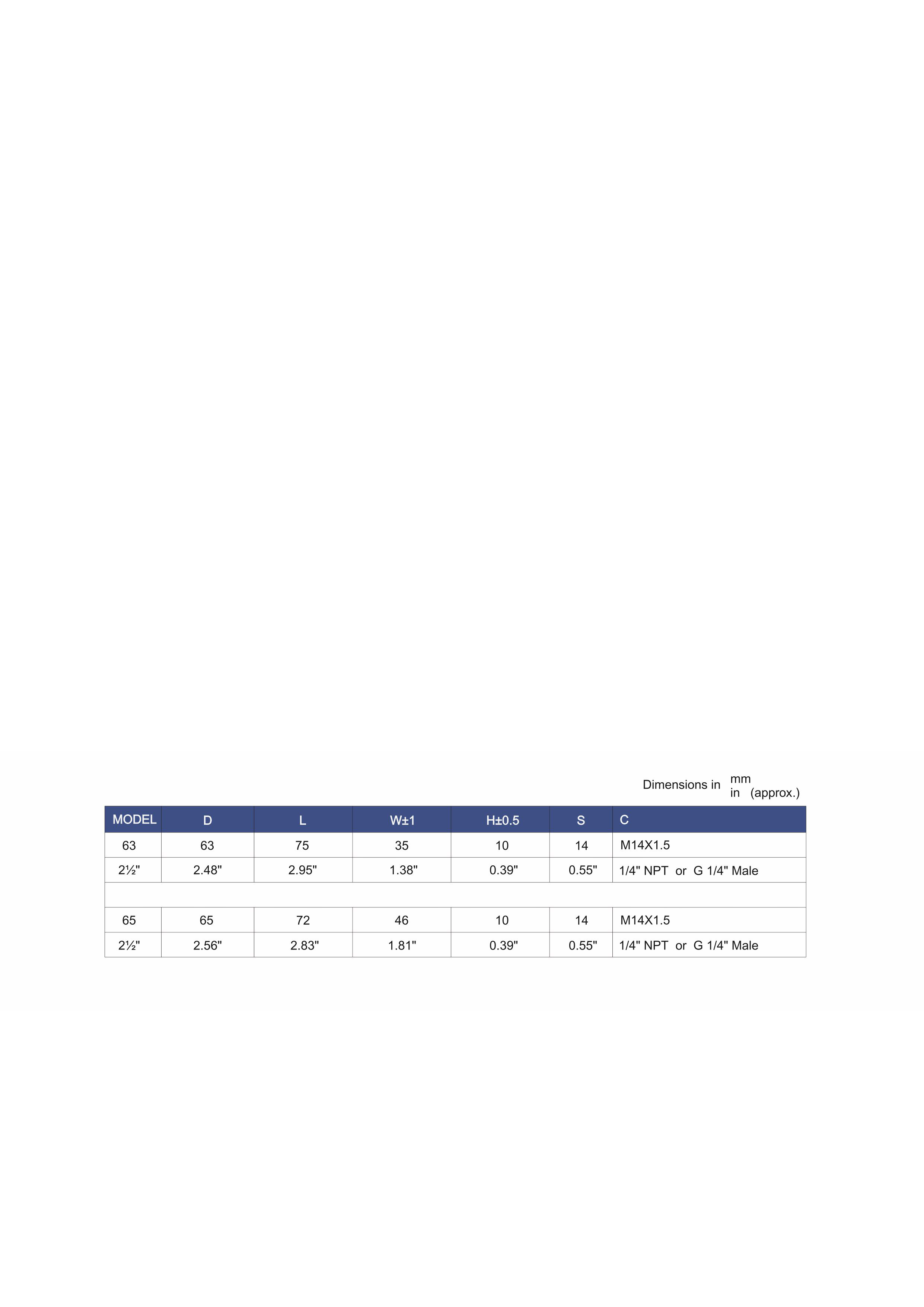

Custom diaphragm seal differential pressure gauges can be tailored to meet specific industry requirements. Manufacturers can adjust parameters such as the material of the diaphragm, the size of the gauge, and the connection fittings based on the application. For example, in the food and beverage industry, materials complying with sanitary standards are often chosen to prevent contamination. Similarly, in chemical processing, corrosion-resistant materials are vital.

Moreover, these custom gauges can be equipped with various features, including electrical output signals for remote monitoring, built-in temperature compensation, and data logging capabilities. This versatility makes them invaluable in industries such as oil and gas, pharmaceuticals, water treatment, and HVAC systems.

In conclusion, custom diaphragm seal differential pressure gauges are essential tools in the accurate measurement of differential pressure across various applications. By combining robust design with customization options, these gauges provide reliable performance, even under the most challenging operational conditions. Their ability to protect sensitive components while ensuring precise measurements makes them a preferred choice for many industries seeking both accuracy and durability in their pressure monitoring solutions.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025