Dec . 21, 2024 22:17 Back to list

custom bourdon type differential pressure gauge

Custom Bourdon Type Differential Pressure Gauge An Overview

In industrial applications, the monitoring of pressure is crucial for ensuring the efficiency, safety, and reliability of systems. One essential instrument used for this purpose is the differential pressure gauge, specifically the custom Bourdon type gauge. This article explores what a Bourdon type differential pressure gauge is, its working principle, applications, and advantages, especially when customized for specific needs.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. It plays a vital role in various applications, from monitoring the performance of filters and compressors to determining the level of liquids in tanks. The differential pressure can indicate anomalies in the system, ensuring that operations remain within the required parameters.

The Bourdon Tube Mechanism

The Bourdon tube, invented by Eugène Bourdon in 1849, is a key component of many pressure gauges, including differential types. This flexible, curved tube expands when pressure is applied, causing the end of the tube to move. This movement is then translated into a rotational movement of the needle on the gauge's dial, displaying the pressure measurement.

In a Bourdon type differential pressure gauge, two Bourdon tubes are typically utilized one for each pressure point being measured. The difference in pressure causes the tubes to deform in varying degrees, and this difference translates into a measurable value.

Customization of Bourdon Type Differential Pressure Gauges

While standard differential pressure gauges may work well for many applications, specific industrial needs can require adaptation. Custom Bourdon type differential pressure gauges can be engineered to accommodate unique process conditions and measurement ranges. Customization may include

1. Material Selection Depending on the fluid being measured—such as corrosive chemicals, high temperatures, or other harsh environments—custom materials can enhance product durability and accuracy.

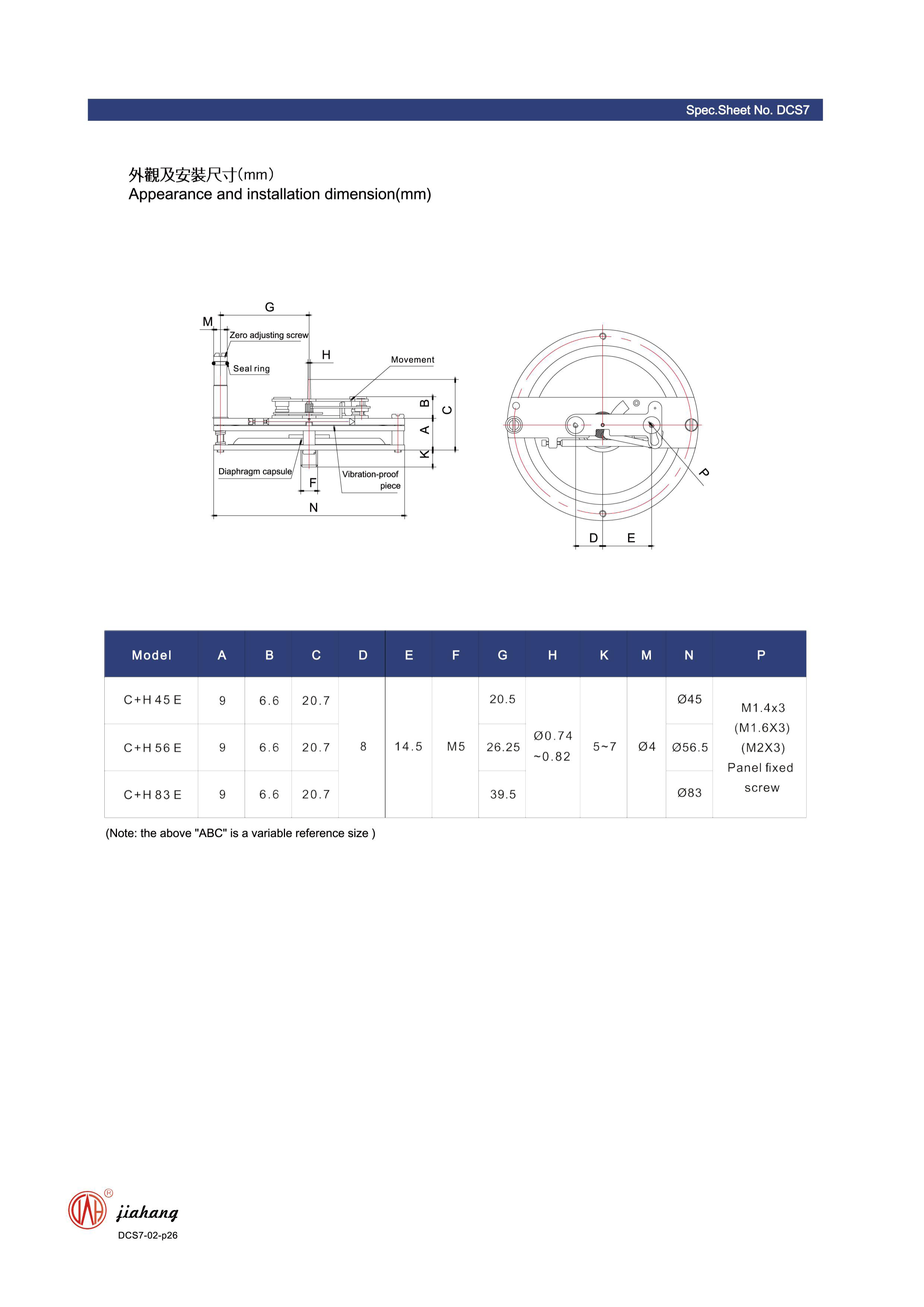

2. Size and Range Custom gauges can be designed to fit particular size constraints or specify pressure ranges that align with system requirements.

3. Output Options For integration into automated systems, custom gauges can provide additional output signals, such as analog or digital outputs, allowing seamless data transfer to control systems.

4. Specialized Calibration Each application may have different calibration needs. Custom calibration ensures that the gauge provides accurate readings under specific operating conditions.

custom bourdon type differential pressure gauge

5. Environmental Protection Custom gauges can also be designed with additional features such as hermetic sealing, enhanced IP ratings for water and dust resistance, and temperature compensation, making them suitable for challenging environments.

Applications of Custom Bourdon Type Differential Pressure Gauges

The versatility of the custom Bourdon type differential pressure gauges leads to their application across various industries, including

- Oil and Gas Monitoring pressures in pipelines and vessels to ensure safe and efficient operations. - Water Treatment Measuring pressure drops across filters to signal when maintenance is needed.

- HVAC Systems Ensuring proper airflow and system performance by monitoring the difference in pressure between various points in the ductwork.

- Pharmaceuticals Accurate pressure measurement in critical processes, where even small variances can significantly affect product quality.

- Food and Beverage Ensuring compliance with safety standards by monitoring differential pressure in packaging and processing systems.

Advantages of Custom Bourdon Type Differential Pressure Gauges

Custom Bourdon type differential pressure gauges offer several advantages

- Precision and Reliability Tailored manufacturing ensures accurate measurements suited to specific applications, improving reliability.

- Enhanced Durability Using materials appropriate for the intended environment enhances the lifespan of the gauge, reducing maintenance costs.

- Improved Performance A custom gauge optimally designed for your process parameters can lead to better performance and increased efficiency in your systems.

In conclusion, the custom Bourdon type differential pressure gauge is an invaluable tool in industrial settings. By providing precise measurements, ensuring compatibility with various fluids and conditions, and enabling integration into complex systems, these gauges contribute to operational efficiency and safety across numerous applications. Customization not only enhances the functionality of these instruments but also supports unique industrial needs, demonstrating the importance of precision engineering in today’s demanding environments.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025