Nov . 22, 2024 07:23 Back to list

cryogenic differential pressure gauges company

Exploring Cryogenic Differential Pressure Gauges Innovations and Applications

In the evolving world of technology and engineering, the importance of precise measurement cannot be overstated, particularly in industries dealing with extreme temperatures. Among the myriad of measurement devices available today, cryogenic differential pressure gauges stand out as essential tools in various applications, from research and development to industrial processes.

Understanding Cryogenic Differential Pressure Gauges

Cryogenic differential pressure gauges are specialized instruments designed to measure pressure differences in environments with temperatures significantly below freezing, typically below -150 degrees Celsius (-238 degrees Fahrenheit). These gauges operate under the unique pressures characteristic of cryogenic fluids like liquid nitrogen, helium, and hydrogen. Their primary function is to monitor variations in pressure between two points in a system, which is crucial for ensuring the safety, efficiency, and reliability of operations.

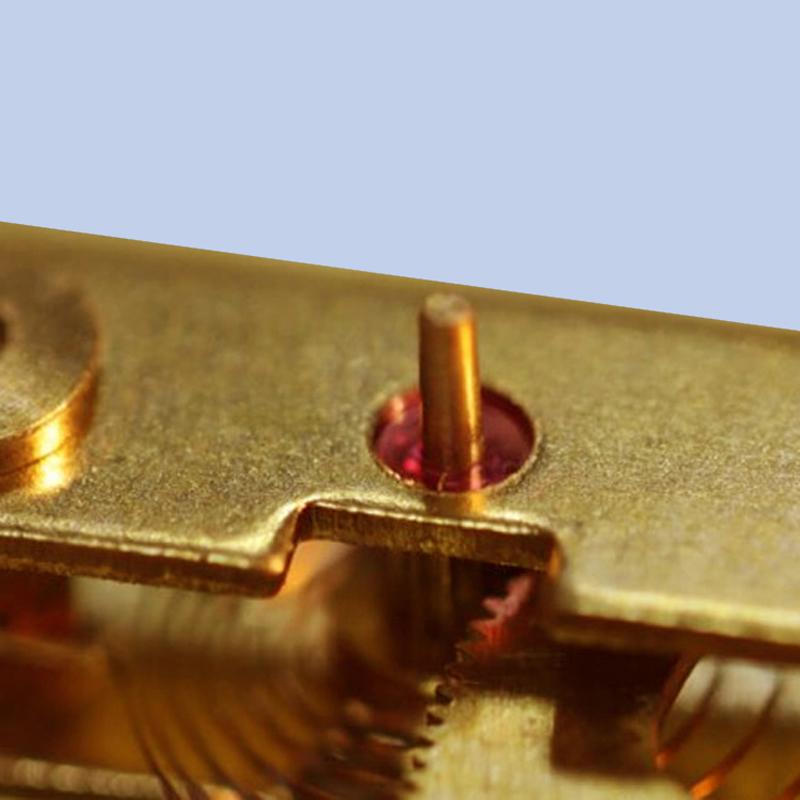

The technology behind these gauges involves materials and designs that can withstand the extreme conditions present in cryogenic applications. The components must be able to perform accurately without suffering from thermal expansion issues or material failure due to the intense cold. Additionally, these gauges need to be capable of providing precise readings in real-time, enabling operators to make informed decisions regarding the systems they monitor.

Applications in Various Industries

Cryogenic differential pressure gauges find applications across a wide range of industries. In the aerospace sector, for instance, they play a critical role in the storage and transfer of cryogenic fuels, where maintaining the right pressure is imperative for safe launch operations. Similarly, in the medical field, these gauges are essential in cryopreservation processes, where samples need to be maintained at extremely low temperatures to preserve their integrity.

The oil and gas industry also utilizes cryogenic differential pressure gauges in liquefied natural gas (LNG) operations. Monitoring pressure differences helps in optimizing the flow of LNG and ensuring the integrity of storage tanks. Moreover, in research facilities, these gauges are invaluable for experiments involving cryogenic temperatures, allowing scientists to gather accurate data without the risk of measurement inaccuracies that could lead to erroneous results.

cryogenic differential pressure gauges company

Innovations Driving the Market

The demand for cryogenic differential pressure gauges continues to drive innovation in the field. Manufacturers are focusing on enhancing the robustness and accuracy of these gauges, incorporating advanced materials that can resist thermal stress while ensuring high sensitivity. Innovations such as digital readouts, wireless connectivity, and integration with IoT technologies are also becoming commonplace. These advancements not only simplify the monitoring process but also enhance the overall efficiency of operations.

Furthermore, with an increasing emphasis on sustainability and energy efficiency, manufacturers are looking to improve the environmental footprint of these gauges. This includes optimizing designs for reduced power consumption and utilizing materials that are both cost-effective and eco-friendly.

Choosing the Right Gauge

When selecting a cryogenic differential pressure gauge, it is crucial to consider various factors, including the specific application, the range of pressure to be measured, and the operating environment. It is essential to work closely with manufacturers who can provide tailored solutions based on unique operational requirements. The right gauge can significantly enhance safety and operational efficiency, ultimately leading to cost savings and improved performance in cryogenic systems.

Conclusion

As industries increasingly rely on cryogenic technologies, the role of cryogenic differential pressure gauges will only become more significant. Their capability to ensure precise measurements in extreme conditions is vital for driving advancements in various fields. As innovation continues to flourish in this sector, we can anticipate the development of even more sophisticated gauges that will meet the growing demands of modern applications, paving the way for safer and more efficient operations in cryogenic environments.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025