Dec . 28, 2024 17:08 Back to list

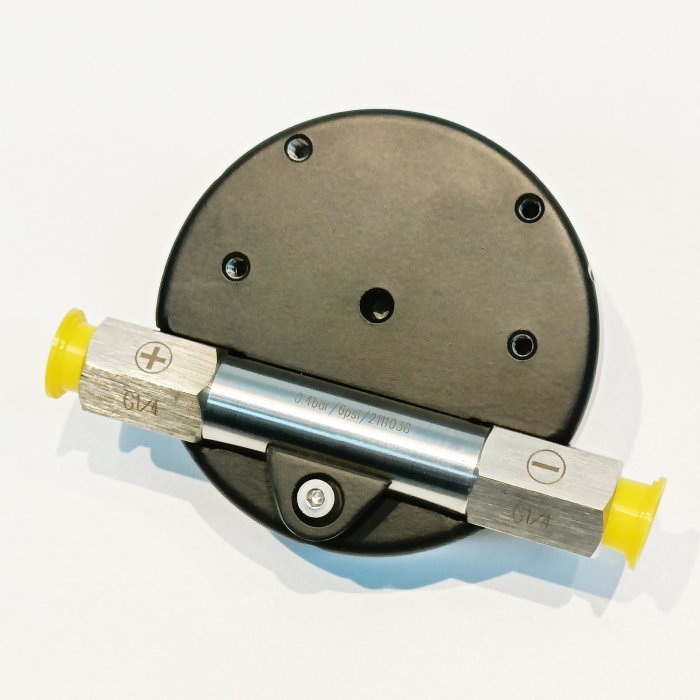

China-made differential pressure gauge with switch for industrial applications and monitoring

Understanding Differential Pressure Gauges with Switches

Differential pressure gauges are crucial instruments used in various industrial applications to measure the difference in pressure between two points. These gauges play a vital role in monitoring the performance of systems, ensuring safety, and maintaining efficiency. Among the many types of differential pressure gauges available in the market, those equipped with switches are particularly valuable due to their ability to provide both visual and automatic signals when specific pressure thresholds are reached. This article explores the features, functions, and applications of differential pressure gauges with switches, focusing on their importance in industrial processes.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the pressure difference between two points in a system, which can indicate flow rates, filter conditions, or the performance of various equipment. The basic principle involves two pressure inputs one measuring the static pressure and the other acting as a reference point. The gauge displays the difference, helping operators and engineers make informed decisions regarding equipment operation or maintenance.

The Importance of Switches in Differential Pressure Gauges

When differential pressure gauges are equipped with switches, they can enhance monitoring capabilities significantly. These switches typically trigger alerts or alarms when the measured pressure difference exceeds or falls below predefined values. This functionality enables timely interventions, preventing potential failures or hazardous conditions.

The integration of switches in differential pressure gauges serves several critical purposes

1. Automated Monitoring Continuous monitoring of pressure differences allows automated systems to react promptly. For example, in HVAC systems, a differential pressure gauge with a switch can automatically adjust airflow based on filter conditions, ensuring optimal performance.

2. Safety Alerts In processes involving hazardous fluids or gases, rapid changes in pressure differentials can indicate leaks or blockages. A switch can activate alarms, notifications, or automatic safety shut-offs to mitigate risks.

china wika differential pressure gauge with switch

3. Maintenance Optimization Differential pressure gauges help monitor the condition of filtration systems. A significant increase in pressure differential across a filter often signals the need for maintenance or replacement. Early detection through switch activation helps avoid unplanned downtime.

4. Energy Efficiency By ensuring that systems operate within their specified pressure difference range, these gauges help maintain energy efficiency. Automatic adjustments can minimize excessive energy consumption and related costs.

Applications of Differential Pressure Gauges with Switches

Differential pressure gauges with switches find applications across various industries, given their versatility and reliability. Common applications include

- HVAC Systems They ensure optimal airflow and efficient operation of air handling units and filters by monitoring pressure differences. - Water and Wastewater Treatment In these facilities, monitoring the pressure differential across filters and membranes is critical for system efficiency and compliance with environmental regulations.

- Pharmaceutical and Food Industries Maintaining precise pressure differentials is vital in cleanroom environments and processes requiring controlled conditions. Differential pressure gauges help monitor and ensure adherence to stringent guidelines.

- Industrial Machinery Many manufacturing processes involve critical pressure conditions. The integration of differential pressure gauges with switches allows for real-time monitoring and automatic adjustments in machinery operation.

Conclusion

Differential pressure gauges with switches are indispensable tools in modern industrial settings. Their ability to monitor pressure differences while providing automated alerts helps enhance safety, efficiency, and performance across numerous applications. By integrating these gauges, industries can reduce operational risks, lower maintenance costs, and improve overall system reliability. As technology continues to evolve, the capabilities of differential pressure gauges are expected to expand, further solidifying their importance in industrial processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025