Nov . 07, 2024 16:50 Back to list

China Rueger Diaphragm Pressure Gauge for Accurate Pressure Measurement Solutions

Understanding the China Rueger Diaphragm Pressure Gauge

Pressure measurement is a critical aspect of various industrial processes, ensuring safety, efficiency, and reliability. Among the various types of pressure measuring devices, the diaphragm pressure gauge is particularly favored for its accuracy and robustness. One prominent provider in this market is China Rueger, known for its high-quality diaphragm pressure gauges that cater to diverse industrial needs. In this article, we will explore the features, applications, and benefits of the China Rueger diaphragm pressure gauge.

The Basics of Diaphragm Pressure Gauges

Diaphragm pressure gauges operate on a simple yet effective principle. They measure the pressure of a medium by utilizing a flexible diaphragm that reacts to the applied pressure. When pressure is exerted on the diaphragm, it deforms and causes a pointer to move across a calibrated scale, indicating the pressure reading. This design allows diaphragm gauges to handle a wide range of pressures while providing accurate and consistent readings.

One of the key advantages of diaphragm pressure gauges is their ability to measure pressure in corrosive and harsh environments. The diaphragm can be made from various materials such as stainless steel, aluminum, and various elastomers, allowing them to be tailored for specific applications. This makes them ideal for industries such as chemical processing, oil and gas, and food and beverage production.

Features of China Rueger Diaphragm Pressure Gauges

China Rueger diaphragm pressure gauges stand out due to their exceptional design and engineering. Some renowned features include

1. Durability Constructed from high-quality materials, these gauges are designed to withstand severe environmental conditions, ensuring longevity and reliability.

2. Precision With advanced calibration techniques, Rueger gauges provide accurate measurements, essential for critical processes that demand precision.

3. Versatility Available in various sizes and pressure ranges, these gauges can be used in a wide array of applications, from low-pressure measurements in HVAC systems to high-pressure requirements in industrial settings.

4. Easy Installation The designs are user-friendly, allowing for straightforward installation and integration into existing systems without significant modifications.

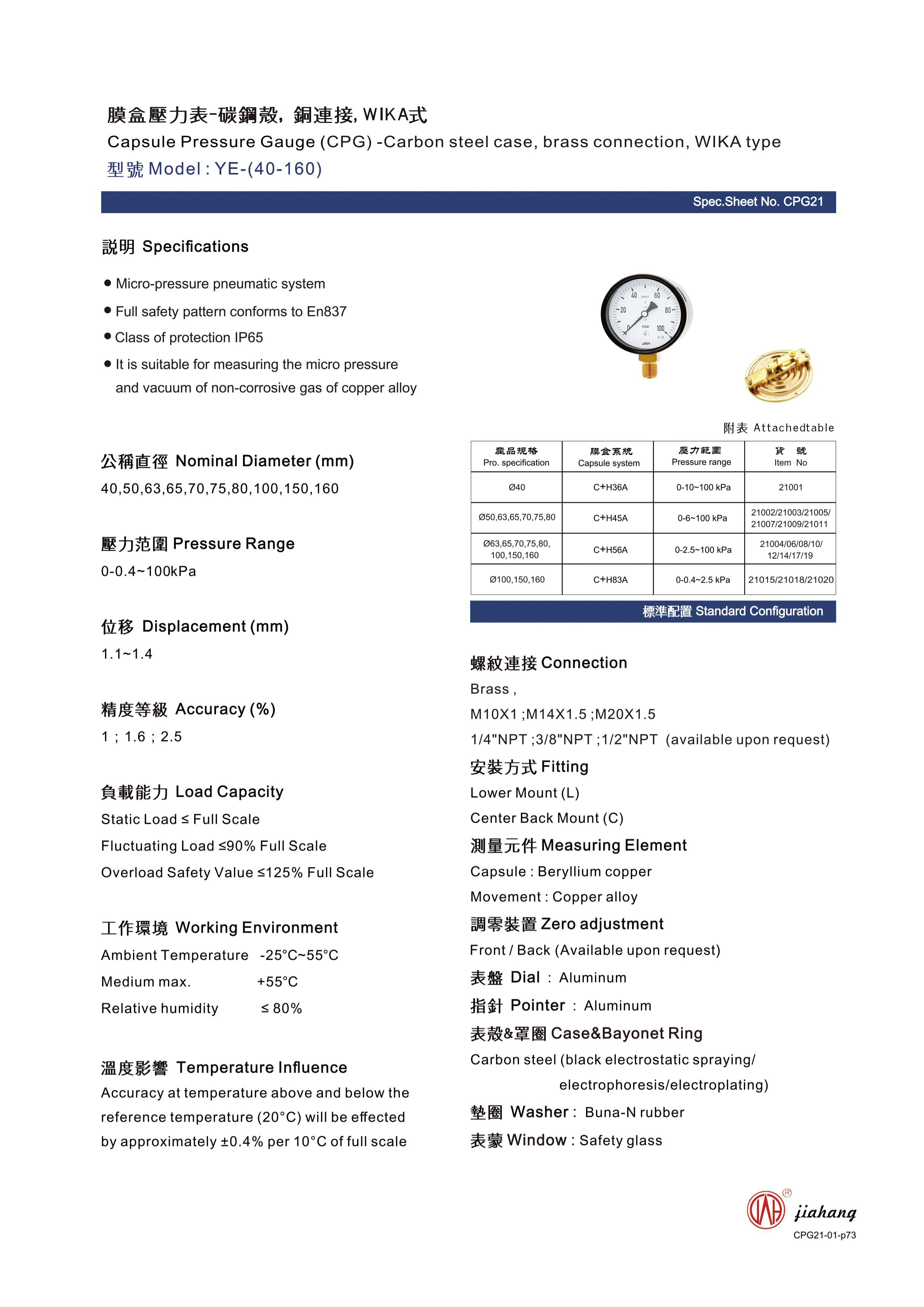

china rueger diaphragm pressure gauge

5. Safety Reliability in pressure measurement is crucial for operational safety. Rueger's diaphragm gauges are designed to minimize failure risks, thereby enhancing workplace safety.

Applications of Diaophgram Pressure Gauges

China Rueger diaphragm pressure gauges find applications across innumerable industries. Some key sectors include

- Chemical Industry In chemical processing plants, controlling and measuring the pressure of gases and liquids is vital. Diaphragm gauges help maintain optimal conditions for safe reactions.

- Oil and Gas These gauges are used in drilling, refining, and transportation processes, where accurate pressure measurements are essential for operational efficiency and safety.

- Food and Beverage In this industry, hygiene and accurate measurements are paramount. Diaphragm pressure gauges ensure the right pressure levels during the processing and packaging of various food products.

- Pharmaceuticals Precision in pressure measurement is crucial in the pharmaceutical industry to ensure compliance with stringent quality control standards.

Conclusion

In conclusion, the China Rueger diaphragm pressure gauge is an essential tool for industries requiring reliable and accurate pressure measurements. Its durability, precision, and versatility make it suitable for a wide range of applications, from chemical processing to food production. As industries continue to evolve and demand higher standards of efficiency and safety, diaphragm pressure gauges from reputable manufacturers like China Rueger will remain a core component in maintaining operational integrity.

Investing in quality measuring instruments such as the Rueger diaphragm pressure gauge not only enhances product quality and safety but also contributes to the overall efficiency of industrial processes. As technological advancements continue, we can expect further innovations in gauge design and functionality, ensuring that industries can effectively meet future challenges.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025