Dec . 04, 2024 00:22 Back to list

China's Pressure Diaphragm Capsule Component for Efficient Fluid Control Solutions

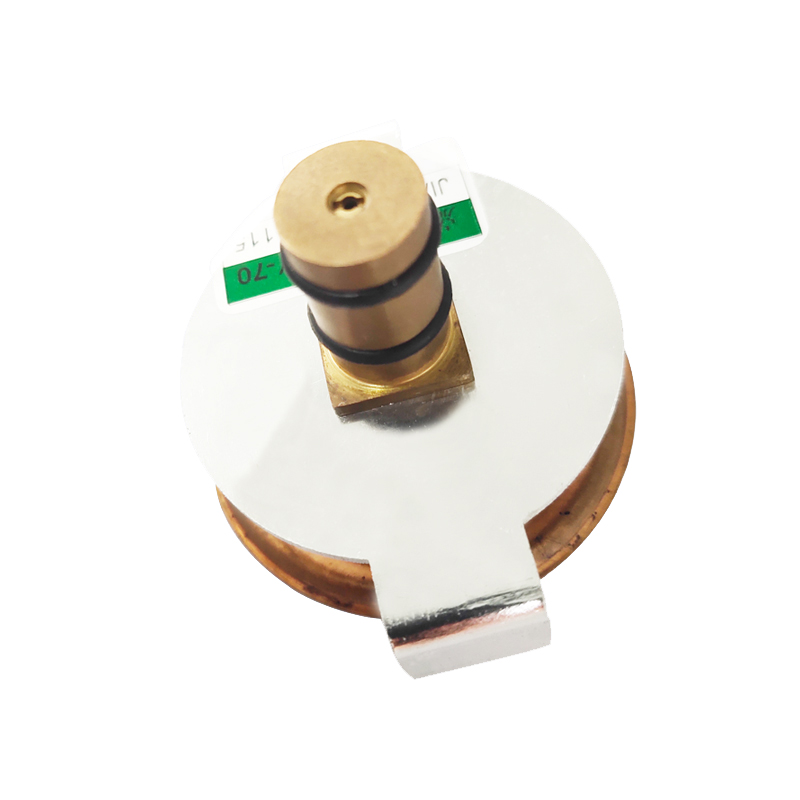

Understanding the China Pressure Diaphragm Capsule Element

In the ever-evolving field of engineering and manufacturing, pressure measurement plays a crucial role in various applications across industries. One of the key components in pressure measurement technology is the pressure diaphragm capsule element, which is integral to ensuring accurate and reliable readings. This article delves into the significance, working mechanism, and applications of the China pressure diaphragm capsule element, shedding light on its importance in modern technology.

What is a Pressure Diaphragm Capsule Element?

A pressure diaphragm capsule element is a type of transducer that converts pressure into an electrical signal or mechanical movement. The design typically includes a flexible diaphragm that responds to changes in pressure, allowing it to measure a wide range of pressures effectively. When pressure is applied to one side of the diaphragm, it deflects, and this deflection is measured either through an electrical method (like piezoelectric sensors) or through mechanical means (like Bourdon tubes).

The significance of the diaphragm's material and construction cannot be overstated. Diaphragms can be made from various materials, including stainless steel, polymers, or specialized alloys, depending on the application's requirements, such as chemical compatibility, temperature resistance, and pressure range.

The Chinese Manufacturing Landscape

China has emerged as a global leader in the production of various industrial components, including pressure measurement instruments. The country boasts a vast network of factories equipped with advanced technologies, enabling the mass production of high-quality pressure diaphragm capsule elements. The competitive pricing and diverse product offerings from Chinese manufacturers make it an attractive destination for businesses looking to source pressure measurement technology.

Moreover, the Chinese government has been investing heavily in modernizing its manufacturing sector. Initiatives like Made in China 2025 aim to enhance innovation and quality across various industries, including instrumentation. As a result, the pressure diaphragm capsule elements produced in China not only meet but often exceed international standards, making them highly sought after in the global market.

Working Mechanism of Diaphragm Capsule Elements

The working principle of pressure diaphragm capsule elements is relatively straightforward yet ingenious. When pressure is exerted on the diaphragm, it undergoes elastic deformation. This deformation varies with the magnitude of the pressure applied. Sensors attached to the diaphragm translate this mechanical deformation into a measurable signal.

china pressure diaphragm capsule element

In many applications, this signal is converted into a digital readout, allowing for real-time monitoring and data logging

. Modern pressure gauges often incorporate smart technologies, enabling wireless data transmission and integration with advanced control systems, further enhancing their functionality.Applications of Pressure Diaphragm Capsule Elements

The applications of pressure diaphragm capsule elements are extensive and spread across various sectors

1. Industrial Automation In manufacturing plants, these elements help in monitoring and controlling processes that rely on accurate pressure readings. They ensure safety and efficiency by providing real-time data.

2. Oil and Gas Industry In this sector, pressure diaphragm elements are crucial for measuring the pressure in pipelines and storage tanks, preventing leaks and potential hazards.

3. Medical Devices Pressure measurement is critical in medical equipment like ventilators and infusion pumps where precise dosing and airflow are necessary.

4. Environmental Monitoring In environmental engineering, pressure sensors help monitor water levels, lending themselves to flood prevention and management systems.

5. Aerospace The aerospace industry employs these sensors to monitor cabin pressure and ensure the safety and comfort of passengers.

Conclusion

The China pressure diaphragm capsule element is a vital component in the landscape of industrial automation and measurement technology. With its robust design and reliable performance, it finds applications in numerous fields, ensuring safety, efficiency, and precision. As technology continues to advance, and with ongoing investments in the manufacturing sector, the future of pressure measurement looks promising. Chinese manufacturers are well-positioned to lead the global market, providing high-quality solutions that meet the demands of an increasingly complex industrial environment. Embracing this technology not only enhances operational efficiency but also contributes to a safer and more controlled manufacturing process.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025