Oct . 10, 2024 07:56 Back to list

china precision pressure gauges india

The Rising Importance of Precision Pressure Gauges in India

In recent years, India has seen a remarkable transformation in its industrial landscape, with sectors ranging from manufacturing to healthcare experiencing explosive growth. As industries evolve and modernize, the need for precision instruments has become increasingly critical. Among these instruments, precision pressure gauges play an essential role in ensuring safe and efficient operations.

Understanding Precision Pressure Gauges

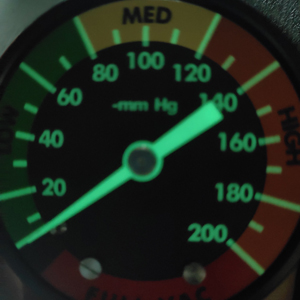

Precision pressure gauges are instruments that measure the pressure of liquids and gases with high accuracy and reliability. Unlike standard pressure gauges, which may suffice for casual monitoring, precision gauges are designed for applications where exact measurements are crucial. They are characterized by their high resolution, minimal hysteresis, and outstanding repeatability. These gauges are essential in various sectors, including oil and gas, chemical manufacturing, pharmaceuticals, and food processing.

The Growing Demand in India

As India further integrates itself into the global economy, the demand for precision instruments, including pressure gauges, has proliferated. The rapid growth of industries such as petrochemicals, energy, and pharmaceuticals necessitates stringent monitoring and control of process parameters, including pressure. In sectors where safety and compliance with international standards are paramount, investing in precision tools becomes non-negotiable.

Additionally, India’s focus on Make in India initiative has led to increased investments in domestic manufacturing capabilities, further driving the need for high-quality measuring instruments. Local manufacturers are rising to meet this demand, providing precision pressure gauges that adhere to international quality standards.

Applications of Precision Pressure Gauges

1. Oil and Gas Industry In the oil and gas sector, precision pressure gauges are employed for measuring pressure at drilling sites, refineries, and during transport. Maintaining accurate pressure readings is crucial for safety, preventing blowouts, and ensuring smooth operations.

2. Pharmaceuticals The pharmaceutical industry requires precise pressure measurements for various applications, including the production of medications and during sterilization processes. Any deviation in pressure can lead to compromised drug quality.

china precision pressure gauges india

3. Food and Beverage Industry In the food sector, maintaining the correct pressure is vital for processes such as canning, brewing, and pasteurization. Precision gauges ensure that these processes are conducted within safe parameters.

4. Manufacturing In manufacturing, precision pressure gauges play a key role in process control. They help monitor hydraulic systems, pneumatic systems, and other applications where pressure levels need to be maintained within strict limits.

Challenges and Innovations

Despite the growing demand for precision pressure gauges, the Indian market faces challenges. One of the primary concerns is the lack of awareness among consumers regarding the importance of investing in high-quality measuring instruments. Often, businesses opt for cheaper alternatives that compromise accuracy and reliability, which can lead to significant downtime and costly errors.

To address these challenges, manufacturers are focusing on innovation. Cutting-edge technology, such as digital pressure gauges equipped with smart sensors, is entering the market. These smart gauges offer enhanced features such as connectivity to IoT devices, enabling remote monitoring and data logging, which can significantly improve operational efficiency.

The Future Outlook

The future of precision pressure gauges in India looks promising. As industries increasingly acknowledge the importance of reliable measurement tools for efficiency and safety, the demand for precision instruments is expected to grow. Moreover, advancements in technology will continue to shape the landscape of pressure measurement, allowing Indian manufacturers to compete on a global scale.

Furthermore, the push for sustainable practices across industries will require precise measurement tools to optimize resource utilization and reduce waste, creating another avenue for growth in this sector.

Conclusion

In summary, precision pressure gauges are becoming indispensable in India’s burgeoning industrial ecosystem. With applications spanning critical sectors, their role in maximizing efficiency, safety, and compliance cannot be overstated. As the market continues to evolve, businesses must recognize the value of investing in high-quality precision gauges to secure their operational integrity and competitiveness in an increasingly demanding environment. The journey of precision instrumentation in India is just beginning, and the potential is limitless as industries strive for excellence.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025