Dec . 01, 2024 13:52 Back to list

China Parker Differential Pressure Gauge Applications and Benefits in Various Industries

Understanding the China Parker Differential Pressure Gauge

In the realm of industrial instrumentation, differential pressure gauges play a crucial role in monitoring and controlling processes. Among the variety of gauges available in the market, the China Parker differential pressure gauge stands out for its reliability, accuracy, and versatility. This article will explore the significance, design, benefits, and applications of the Parker differential pressure gauge, especially in the context of the Chinese industrial landscape.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument that measures the difference in pressure between two points within a system. This measurement is essential for various applications, as it helps in monitoring flow rates, detecting leaks, and ensuring optimal performance of equipment. The gauge typically consists of a flexible diaphragm or other sensing elements that respond to pressure differences, converting them into a readable output.

The Design of Parker Differential Pressure Gauges

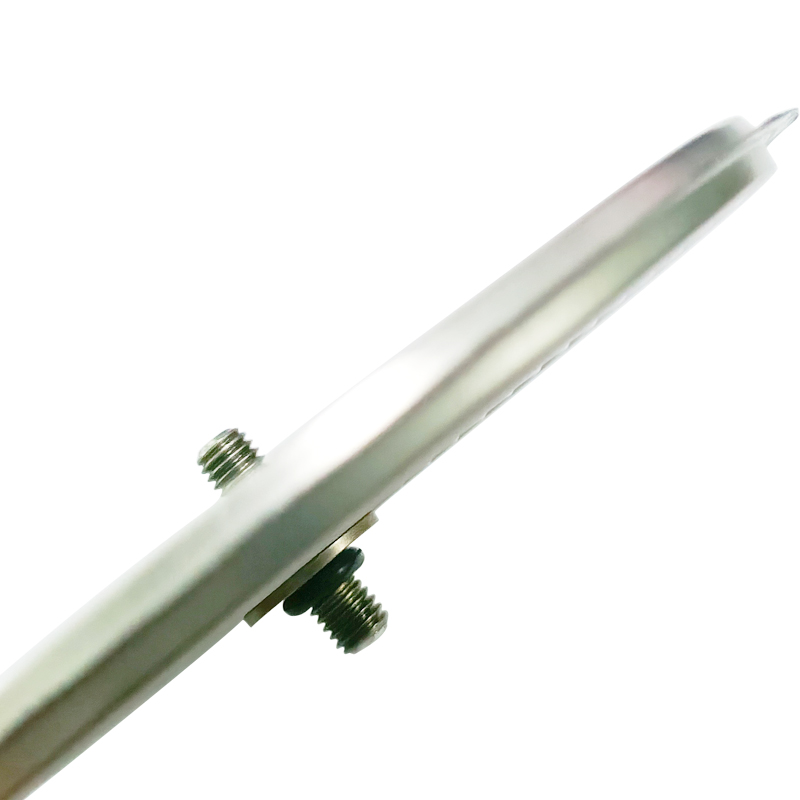

China Parker differential pressure gauges are designed to meet stringent quality standards, ensuring accuracy and longevity in demanding environments. The construction of these gauges often includes a high-precision sensing element, which can be a diaphragm, bellows, or a capacitive sensor. This design allows for reliable readings even in harsh conditions, such as high temperatures and corrosive substances.

The gauges are typically available in both analog and digital formats. Analog gauges feature a traditional dial and needle mechanism, providing an easy-to-read display. In contrast, digital versions offer enhanced features, including data logging, alarms, and remote monitoring capabilities, making them suitable for modern industrial applications.

Advantages of Using Parker Differential Pressure Gauges

1. Accuracy One of the most significant advantages of Parker differential pressure gauges is their high level of accuracy. This precision is critical in industrial applications where pressure deviations can lead to equipment failure or unsafe conditions.

2. Durability Built with high-quality materials, Parker gauges are designed to withstand challenging environments. Their robust construction minimizes the likelihood of failure, ensuring long-term performance.

china parker differential pressure gauge

3. Versatility These gauges can be used in various applications, from HVAC systems to chemical processing. Their ability to measure small pressure differences makes them suitable for diverse industries, including oil and gas, pharmaceuticals, and food processing.

4. Easy Installation and Maintenance The design of Parker differential pressure gauges allows for straightforward installation procedures. Additionally, many models require minimal maintenance, reducing downtime in industrial operations.

5. Cost-Effectiveness Given their durability and reliability, Parker gauges often represent a cost-effective solution for industries. The reduced need for frequent replacements or repairs translates to savings over time.

Applications in the Industry

The applications of China Parker differential pressure gauges are vast, reflecting the versatility of the instrument. In the HVAC industry, these gauges are crucial for monitoring air and liquid flow in ducts and piping systems. By maintaining optimal pressure levels, they contribute to energy efficiency and comfort in residential and commercial spaces.

In the oil and gas sector, differential pressure gauges are used to monitor filter conditions and flow rates, ensuring smooth operations and preventing equipment wear. Similarly, in water treatment facilities, these gauges help measure the pressure drop across filtration systems, alerting operators to potential issues before they escalate.

In the pharmaceutical and food industries, maintaining proper pressure levels is vital for compliance with safety regulations. Parker differential pressure gauges provide the necessary monitoring to ensure that processes remain within stipulated limits, promoting product quality and safety.

Conclusion

The China Parker differential pressure gauge represents a cornerstone technology in the field of industrial measurement and control. With its accuracy, durability, and versatility, it significantly contributes to the efficiency and safety of various industrial processes. As industries continue to evolve, the demand for reliable instrumentation like the Parker differential pressure gauge will undoubtedly grow, reinforcing its role in promoting operational excellence across sectors. Whether in heavy industry or delicate pharmaceutical manufacturing, these gauges are an essential component of modern industrial technology.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025