Oct . 04, 2024 16:25 Back to list

china differential pressure gauge with sealed capilary

Understanding China's Differential Pressure Gauge with Sealed Capillary Features and Applications

In industrial settings, precise measurement of pressure differences is crucial for the safety and efficiency of various processes. Among the tools available for this purpose is the differential pressure gauge, a device specifically designed to measure the pressure between two points. One noteworthy variation is the differential pressure gauge equipped with a sealed capillary, widely used in China and other regions for its reliability and accuracy.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument that measures the difference in pressure between two points within a system. These gauges are commonly used in a variety of applications, including HVAC systems, water treatment plants, and oil and gas industries. By providing accurate measurements, they help maintain optimal performance and safety levels in various processes.

The Sealed Capillary Design

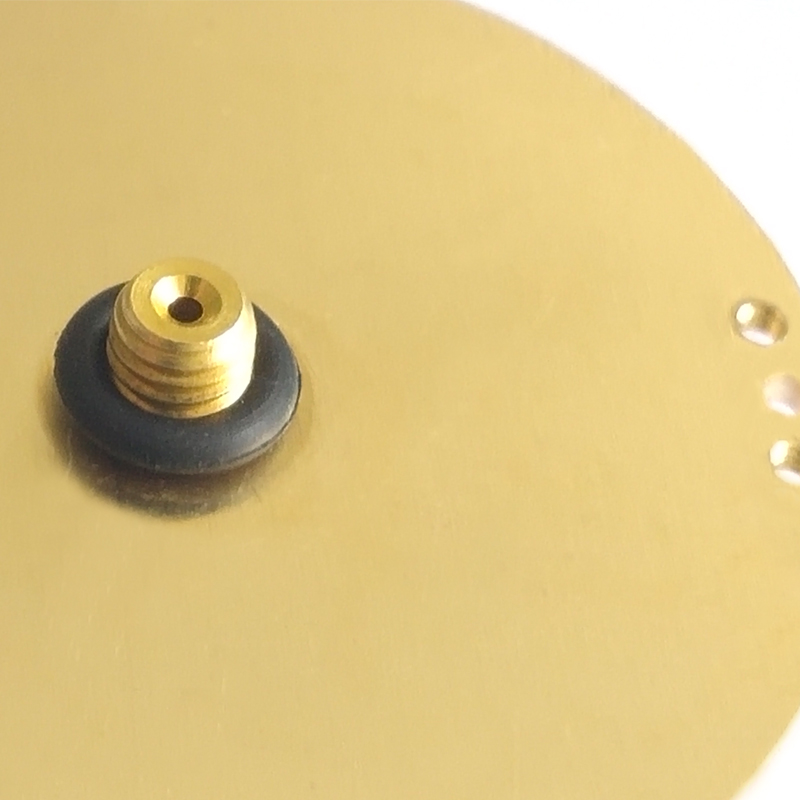

The inclusion of a sealed capillary in differential pressure gauges enhances their functionality and performance. This design consists of a small, flexible tube (the capillary) that connects the measurement points. Being sealed means that the capillary is filled with a liquid or gas that transmits pressure changes from one end to the other without exposure to the surrounding environment. This feature protects the internal fluid from contamination, ensuring the accuracy and longevity of the gauge.

Advantages of the Sealed Capillary Differential Pressure Gauge

2. Protection from Contaminants Since the measurement chamber is sealed, the gauge is sheltered from dirt, moisture, and other contaminants, which can compromise the measurement process.

china differential pressure gauge with sealed capilary

3. Improved Durability Sealed systems tend to be more robust and less prone to damage from external factors, extending the service life of the gauge.

4. Versatility These gauges can be used in a range of temperatures and pressures, making them suitable for various industrial applications.

5. Easy Installation The compact design of the sealed capillary gauge allows for straightforward installation in tight spaces often found in industrial settings.

Applications in Industry

In China, differential pressure gauges with sealed capillaries are integral in various sectors. In the HVAC industry, they monitor air pressure differences across filters to ensure efficient airflow and filter performance. In water treatment facilities, these gauges help regulate the pressure in different stages of treatment, ensuring safe and effective operations.

Furthermore, in the oil and gas sector, they are instrumental in monitoring pipeline pressures, helping to detect leaks and prevent accidents. Their ability to function reliably in extreme conditions makes them invaluable in such critical applications.

Conclusion

The differential pressure gauge with a sealed capillary represents an essential advancement in pressure measuring technology. With its numerous advantages, including enhanced accuracy, protection from contaminants, and versatility across various applications, it plays a vital role in maintaining the safety and efficiency of industrial processes in China and beyond. As industries continue to evolve, the demand for reliable measurement tools like these gauges will likely grow, underscoring the importance of continued innovation in pressure measurement technology.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025