Nov . 22, 2024 00:46 Back to list

china bourdon differential pressure gauge

Understanding the China Bourdon Differential Pressure Gauge

The Bourdon differential pressure gauge, a vital instrument in various industrial applications, plays a crucial role in measuring pressure differences between two points in a system. Particularly in China, the significance of this device has been recognized across several fields, including oil and gas, chemical processing, water treatment, and more. This article delves into the working principles, applications, advantages, and advancements of the Bourdon differential pressure gauge, highlighting its importance in modern industry.

Working Principle

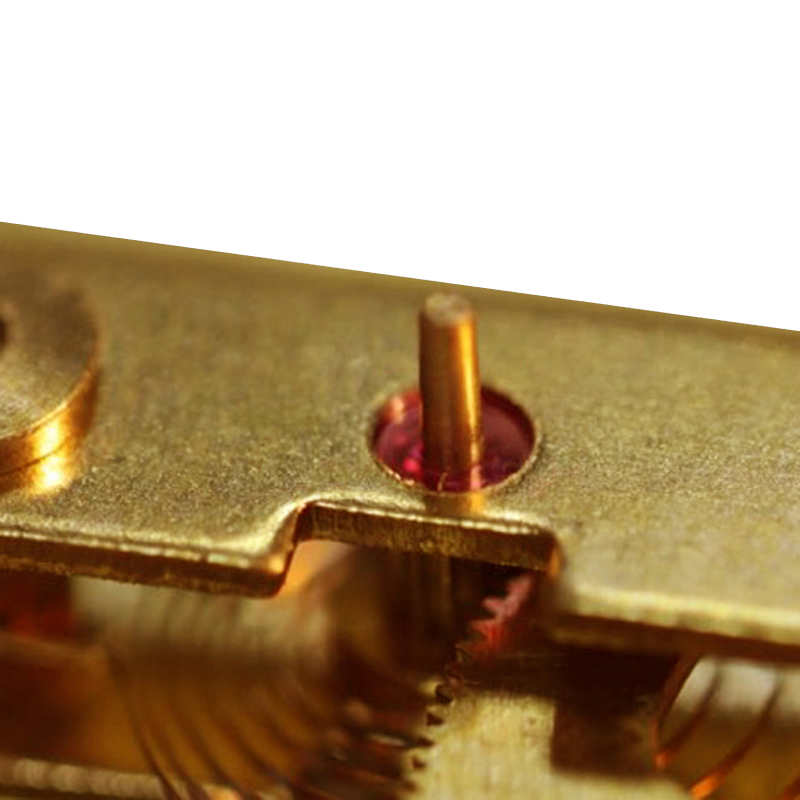

The Bourdon differential pressure gauge operates based on the mechanical movement of a bent tube, known as a Bourdon tube. When pressure is applied to one side of the tube, it tends to straighten out, causing the free end of the tube to move. This movement is then translated into a rotational motion on the gauge’s dial via a series of gears and levers. The difference in pressure between the two points being measured enables the gauge to indicate the differential pressure accurately. This mechanical design ensures that the gauge is robust and reliable under various operating conditions.

Applications

Bourdon differential pressure gauges find applications in a diverse array of industries. In the oil and gas sector, they are used to monitor pressure levels in pipelines and storage tanks, ensuring safety and efficiency. In chemical processing, these gauges help maintain the necessary conditions for reactions and processes by monitoring the differential pressure across filters and reactors. Furthermore, in water treatment facilities, they are essential for tracking filter conditions, thereby ensuring optimal filtration performance. Their versatility makes them indispensable tools in many industrial processes that require precise pressure measurements.

Advantages

china bourdon differential pressure gauge

One of the key advantages of the Bourdon differential pressure gauge is its simplicity and durability. Unlike electronic pressure sensors, which may be susceptible to environmental conditions and require calibration, Bourdon gauges are mechanical devices that can withstand harsh operating environments. They are relatively easy to install and maintain, offering a cost-effective solution for many industries. Additionally, Bourdon gauges provide immediate, real-time readings, which are crucial for time-sensitive applications. Their ability to function without external power sources further enhances their usability in remote or challenging locations.

Advancements in Technology

With technological advancements, the design and functionality of Bourdon differential pressure gauges have evolved significantly. Modern gauges now incorporate materials that enhance their resistance to corrosion, allowing for longer service life in aggressive environments. Manufacturers are also integrating features such as digital displays, data logging capabilities, and remote monitoring systems, making it easier for operators to analyze pressure data and make informed decisions. These innovations not only improve accuracy but also increase the safety and efficiency of industrial processes.

Conclusion

The China Bourdon differential pressure gauge represents a time-tested solution for measuring pressure differences across various industries. Its mechanical design, coupled with its robustness and reliability, has established it as a preferred choice among engineers and technicians. As technology continues to advance, these gauges are becoming even more sophisticated, integrating digital features that cater to the modern industry's demands.

In an ever-evolving industrial landscape, the importance of accurate pressure measurement cannot be overstated. The Bourdon differential pressure gauge stands as a testament to the ingenuity of traditional engineering, updated to meet the contemporary needs of industry. As businesses seek to enhance safety and efficiency, the Bourdon gauge remains a crucial tool in their arsenal, ensuring that their operations run smoothly and effectively. Whether monitoring pressure in critical processes or ensuring optimal conditions in various applications, the Bourdon differential pressure gauge is an essential component in the complex machinery of modern industry.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025