Sep . 13, 2024 13:49 Back to list

china differential pressure gauge diaphragm

Understanding the China Differential Pressure Gauge Diaphragm

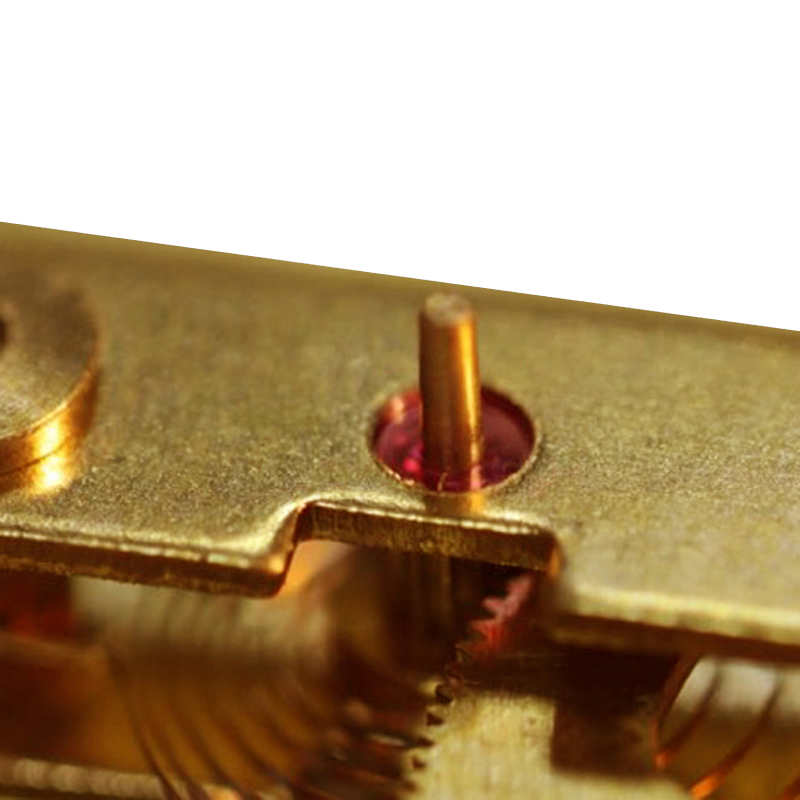

The differential pressure gauge is an essential instrument in various industrial processes, serving to measure the difference in pressure between two points in a system. In China, the design and manufacturing of these gauges, particularly the diaphragm type, have witnessed significant advancements, enabling industries to achieve higher accuracy and reliability in pressure measurement.

A diaphragm differential pressure gauge typically consists of a flexible membrane that responds to pressure changes. When pressure is applied to either side of the diaphragm, it deflects, causing a movement that is translated into a readable measurement. This design not only enhances the sensitivity of the gauge but also minimizes the effects of vibrations and pulsations, which are common in many industrial environments.

One of the key benefits of diaphragm-based gauges is their ability to handle corrosive or viscous fluids. Manufacturers in China have developed materials such as stainless steel and special alloys that can withstand harsh conditions, thereby extending the lifespan and performance of the gauges. This is particularly crucial in industries such as petrochemicals, pharmaceuticals, and food processing, where material compatibility can greatly influence operational safety and product quality.

china differential pressure gauge diaphragm

In addition to durability, Chinese manufacturers have focused on incorporating advanced technologies into differential pressure gauges. Many modern models are equipped with digital displays, allowing for easier readings and improved data accuracy. Some even offer remote monitoring capabilities through connectivity features, which enable operators to track pressure changes in real-time, enhancing process control and efficiency.

The growing emphasis on quality and innovation has positioned China as a significant player in the global market for differential pressure gauges. With a focus on meeting international standards, many Chinese manufacturers are venturing into certifications such as ISO and CE, ensuring that their products not only meet but exceed the expectations of global clients.

Furthermore, the rising demand for automation in industrial processes has propelled the development of more advanced pressure measurement solutions in China. As industries continue to evolve, the role of differential pressure gauges, particularly diaphragm types, will remain critical. They will not only help in monitoring and controlling processes but also contribute to the overall safety and efficiency of operations.

In conclusion, the diaphragm differential pressure gauge represents a significant technological achievement in pressure measurement. With ongoing developments in design and material technology, China is poised to continue its leadership in this sector, providing essential tools for a wide range of industries worldwide.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025