Aug . 28, 2024 22:35 Back to list

High-Performance China Cryogenic Differential Pressure Gauges

Understanding China’s Cryogenic Differential Pressure Gauges

Cryogenic technology plays a critical role in various industries, including aerospace, medical, and energy sectors. As processes involving extremely low temperatures continue to expand, the demand for precise measurement instruments, such as cryogenic differential pressure gauges, is ever-increasing. China has emerged as a significant player in the development and production of these sophisticated devices, which are essential for ensuring safety and efficiency in cryogenic applications.

Differential pressure gauges are instrumental in measuring the pressure difference between two points in a system. In cryogenic applications, they are particularly important as they monitor the pressure variations in tanks and pipelines carrying liquefied gases like nitrogen, helium, and oxygen at low temperatures. These gauges help prevent potential hazards such as leaks, over-pressurization, and equipment failure.

The unique challenge of operating in cryogenic conditions is that traditional pressure measurement technologies may not function effectively. Therefore, China has invested significantly in research and development to create specialized cryogenic differential pressure gauges that can withstand extreme temperatures without compromising accuracy and reliability. These gauges are typically designed with materials that can endure thermal contraction and expansion, ensuring their longevity in demanding environments.

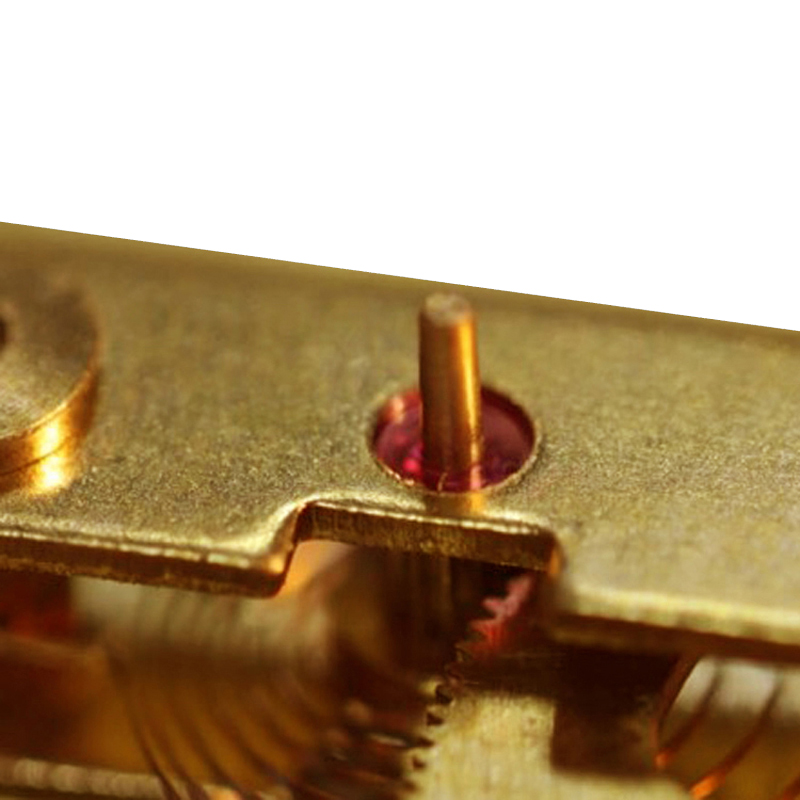

china cryogenic differential pressure gauges

The manufacturing of cryogenic differential pressure gauges in China involves advanced technologies and stringent quality control measures. Chinese manufacturers utilize state-of-the-art production techniques, including precision machining and calibration processes that adhere to international standards. This focus on quality has allowed Chinese products to compete in the global market, catering to companies needing reliable pressure measurement solutions.

Additionally, innovation in the design of these gauges, such as the incorporation of digital technology and remote monitoring capabilities, further enhances their performance. Digital cryogenic differential pressure gauges can provide real-time data, enabling operators to make informed decisions quickly. This technological advancement contributes to higher operational efficiency and enhanced safety protocols in industries reliant on cryogenic processes.

As the global focus shifts toward energy efficiency and sustainable practices, the role of cryogenic differential pressure gauges will continue to grow. China is poised to remain at the forefront of this field, leveraging its manufacturing capabilities and technological advancements. By consistently improving the reliability and precision of these critical instruments, Chinese producers not only enhance their competitive edge but also contribute significantly to global innovations in cryogenic technology.

In conclusion, China’s commitment to developing advanced cryogenic differential pressure gauges illustrates its pivotal role in the evolving landscape of cryogenic applications. With continuous improvements and innovations, these gauges will undoubtedly play a crucial role in ensuring safety and efficiency across various industries.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025