Oct . 12, 2024 06:09 Back to list

Caterpillar Differential Pressure Gauge for Accurate Measurement and Monitoring Solutions

Understanding Caterpillar Differential Pressure Gauges A Comprehensive Overview

In the world of industrial machinery and equipment, the efficiency and reliability of operations are paramount. Among the various tools that contribute to optimal performance, the differential pressure gauge holds a significant place. Caterpillar, a renowned leader in heavy machinery and equipment manufacturing, offers advanced differential pressure gauges that are instrumental in monitoring and maintaining the performance of systems. This article delves into the functionality, applications, and advantages of Caterpillar differential pressure gauges, emphasizing their importance in various industrial settings.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument that measures the difference in pressure between two points in a system. This gauge is vital for applications where pressure differentials are crucial for process control and performance optimization. Differential pressure gauges are widely used in various industries, including oil and gas, water treatment, HVAC systems, and manufacturing.

How Does a Caterpillar Differential Pressure Gauge Work?

Caterpillar differential pressure gauges operate by utilizing two pressure sensing ports. The gauge senses the pressure from the two distinct points and calculates the difference, displaying it on an analog or digital readout. This measurement can indicate whether filters are clogged, pumps are functioning correctly, or if there are any irregularities in the system, allowing operators to make informed decisions to maintain efficiency.

Key Features of Caterpillar Differential Pressure Gauges

1. Durability and Reliability Caterpillar products are synonymous with durability. Their differential pressure gauges are designed to withstand harsh operating environments, ensuring accurate readings over extended periods, even in challenging conditions.

2. Easy to Read Caterpillar gauges come with clear and concise readings, whether in analog or digital format. This feature enables technicians and operators to grasp critical information quickly, facilitating timely decision-making.

3. Versatile Applications These gauges can be used in a wide range of applications, from monitoring engine performance to overseeing fluid transfer processes in various machinery, showcasing their versatility.

4. Calibration and Maintenance Caterpillar differential pressure gauges are designed to be easy to calibrate and maintain, ensuring that they remain accurate and reliable throughout their operational life.

5. Integration with Advanced Systems Many Caterpillar gauges are compatible with advanced monitoring systems, allowing for real-time data analysis and integration into broader operational frameworks.

Applications of Caterpillar Differential Pressure Gauges

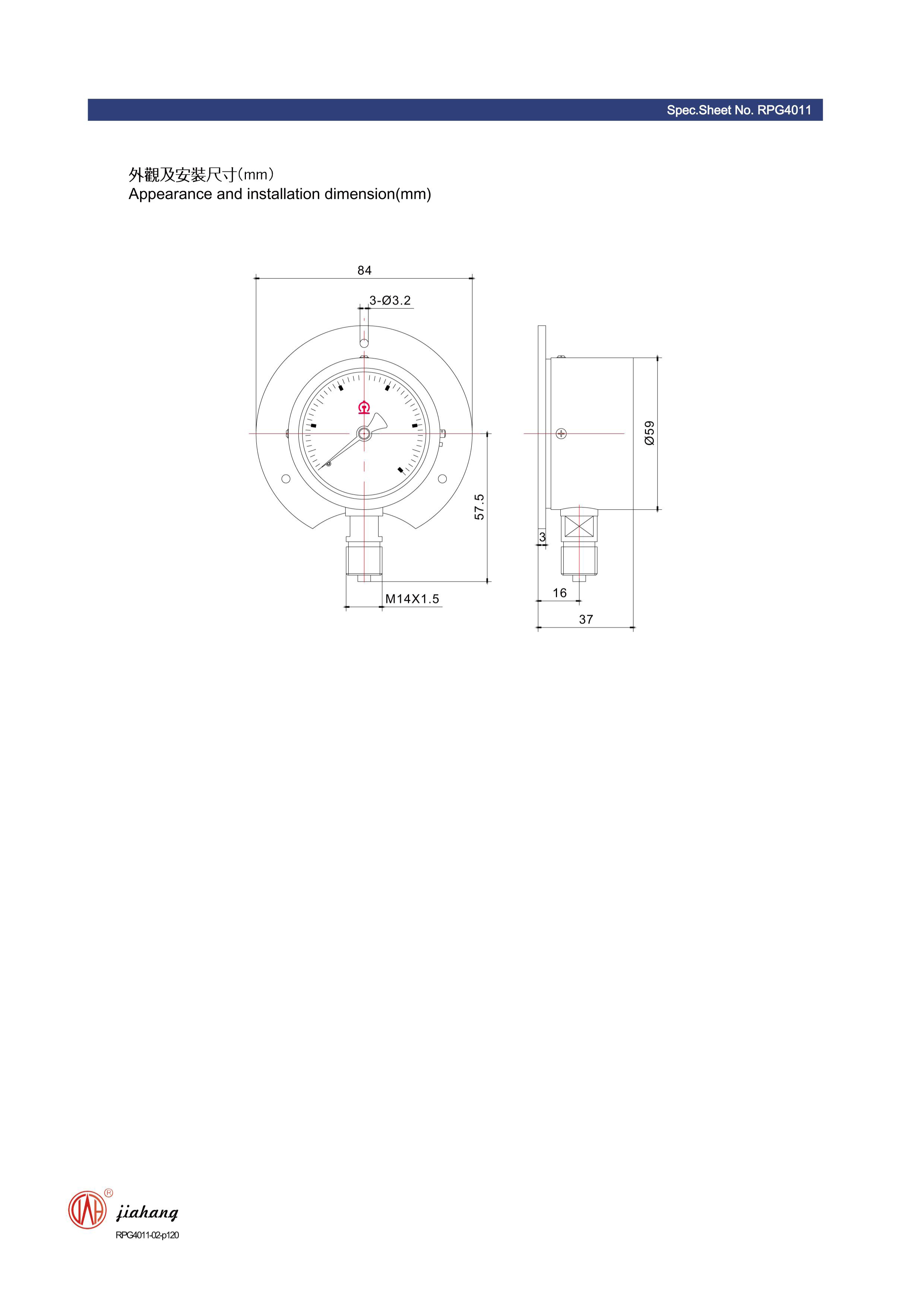

caterpillar differential pressure gauge product

Caterpillar differential pressure gauges are employed in multiple applications, including

- Filtration Monitoring In industrial settings, these gauges assist in monitoring filter performance. A rise in differential pressure across a filter indicates potential clogging, prompting timely maintenance.

- Pump Performance Monitoring pressure differentials can help assess the efficiency of pumps. A consistent drop in differential pressure may signal wear or loss of performance, necessitating repairs or replacements.

- Process Control In manufacturing, differential pressure gauges help maintain optimal conditions by monitoring pressure levels in various processes, ensuring that systems operate within their designed parameters.

- HVAC Systems These gauges play a crucial role in HVAC systems, helping maintain the balanced performance of air filters and ductwork by tracking pressure differentials.

Advantages of Using Caterpillar Differential Pressure Gauges

Investing in Caterpillar differential pressure gauges offers numerous benefits

1. Enhanced Operational Efficiency By providing accurate pressure readings, these gauges help prevent equipment failures and downtime, leading to increased productivity.

2. Cost Savings Early detection of issues related to pressure differentials can significantly reduce maintenance costs and prevent costly repairs.

3. Improved Safety Monitoring pressure levels is crucial for maintaining safe working conditions. By ensuring that systems operate within safe parameters, the risk of accidents is minimized.

4. Brand Reliability Caterpillar's reputation for quality and innovation means customers can trust their products to perform in demanding situations consistently.

Conclusion

Caterpillar differential pressure gauges represent a crucial component of modern industrial operations, offering essential insights for maintaining system performance and efficiency. Their robust design, versatility, and ease of use make them indispensable tools across various industries. As businesses increasingly rely on data-driven maintenance strategies, the role of advanced gauges like those offered by Caterpillar will continue to grow, supporting the pursuit of efficiency, safety, and reliability in industrial operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025