Oct . 06, 2024 16:16 Back to list

caterpillar differential pressure gauge exporter

Understanding Caterpillar Differential Pressure Gauge Exporters

In the industrial landscape, differential pressure gauges play a crucial role in monitoring and controlling various processes. Caterpillar, a renowned name in heavy machinery and equipment, specializes in producing high-quality differential pressure gauges suited for different applications. This article delves into the significance of Caterpillar differential pressure gauge exporters, focusing on their features, benefits, and the global market dynamics that drive their use.

What are Differential Pressure Gauges?

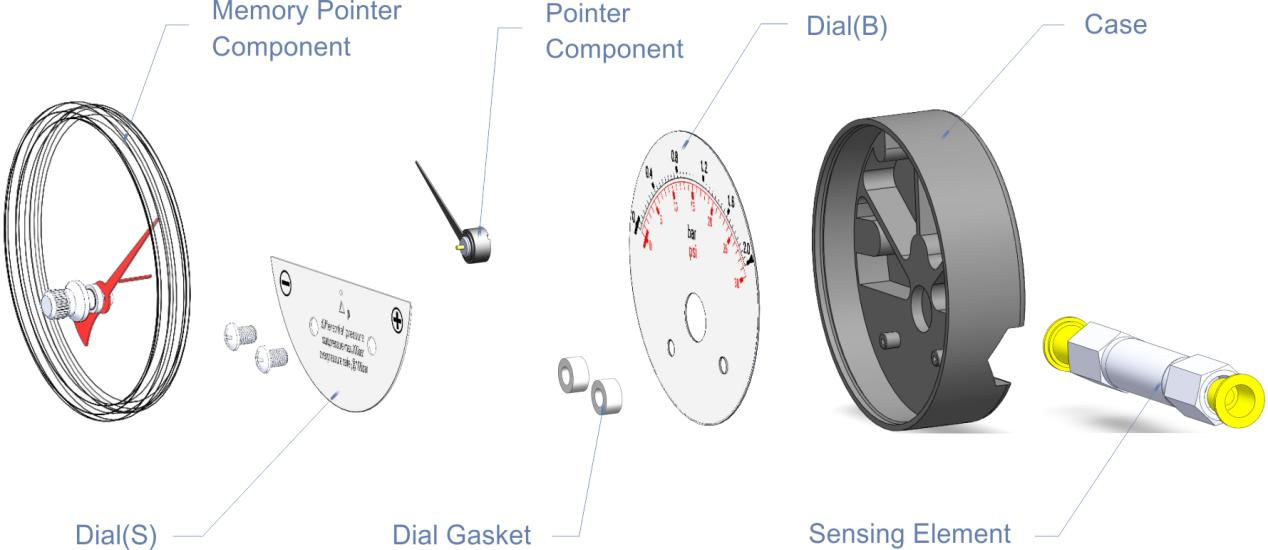

Differential pressure gauges are instruments that measure the difference in pressure between two points within a system. They are essential in various industries, including oil and gas, water treatment, pharmaceuticals, and manufacturing. These gauges help monitor filtration processes, flow rates, and equipment performance. Their ability to provide real-time data enhances decision-making and operational efficiency.

Caterpillar’s Market Position

Caterpillar has established itself as a leader in manufacturing high-performance differential pressure gauges. The company's reputation is built on its commitment to quality, durability, and innovation. These gauges are designed to withstand harsh environmental conditions, making them suitable for both outdoor applications and demanding industrial settings. Caterpillar's differential pressure gauges are known for their accuracy, reliability, and ease of installation, which further solidifies the company's strong position in the market.

Exporting Differential Pressure Gauges

The export of Caterpillar differential pressure gauges represents a significant aspect of the company’s global strategy. With a focus on providing high-quality products to international markets, Caterpillar leverages its extensive distribution network to reach customers worldwide. Exporting these gauges involves not only selling the products but also understanding the diverse regulatory standards and market needs in different regions. This adaptability is crucial for maintaining Caterpillar's competitive edge in the global marketplace.

caterpillar differential pressure gauge exporter

Advantages of Using Caterpillar Differential Pressure Gauges

1. Quality Assurance Caterpillar's commitment to quality assurance means that customers can rely on their products to perform consistently over time. Each gauge undergoes rigorous testing to ensure it meets the highest standards.

2. Advanced Technology Caterpillar continuously invests in research and development, integrating the latest technologies into its differential pressure gauges. This results in enhanced functionality, such as digital displays, wireless monitoring capabilities, and improved accuracy.

3. Professional Support Caterpillar does not just offer products; they provide extensive customer support to help clients select the right gauge for their application, install it correctly, and maintain it over time. This level of service reinforces customer loyalty and satisfaction.

4. Global Reach Through their export strategy, Caterpillar makes its differential pressure gauges available across various countries and industries, thereby meeting the growing demand for reliable measuring instruments.

Conclusion

Caterpillar differential pressure gauge exporters play a pivotal role in the global industrial sector. By consistently delivering high-quality, technologically advanced products, Caterpillar enhances operational efficiency and safety across various applications. Their commitment to quality, supported by a robust export strategy, ensures that customers worldwide benefit from reliable and precise measurements. As industries continue to evolve and demand more efficient monitoring tools, Caterpillar's differential pressure gauges will undoubtedly remain at the forefront, contributing to improved performance and sustainability in industrial operations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025