Dec . 05, 2024 14:17 Back to list

carbon dioxide fire extinguisher pressure gauge factory

Understanding the Importance of Pressure Gauges in Carbon Dioxide Fire Extinguishers

Fire safety is an essential aspect of any environment, be it residential, commercial, or industrial. One of the most effective means of controlling and extinguishing fires is the use of carbon dioxide (CO2) fire extinguishers. These devices are crucial for combating fires caused by flammable liquids and electrical equipment, where traditional water extinguishers would be ineffective. To ensure that these extinguishers work correctly when needed, the pressure gauge is a vital component that should never be overlooked.

The Role of Carbon Dioxide Fire Extinguishers

CO2 fire extinguishers operate by displacing oxygen and cooling the fire's heat to suffocate it. They are particularly effective for Class B and Class C fires, which involve flammable liquids and electrical equipment, respectively. The primary advantage of using CO2 extinguishers is that they do not leave any residue, making them suitable for use in electronic facilities, laboratories, and other sensitive environments.

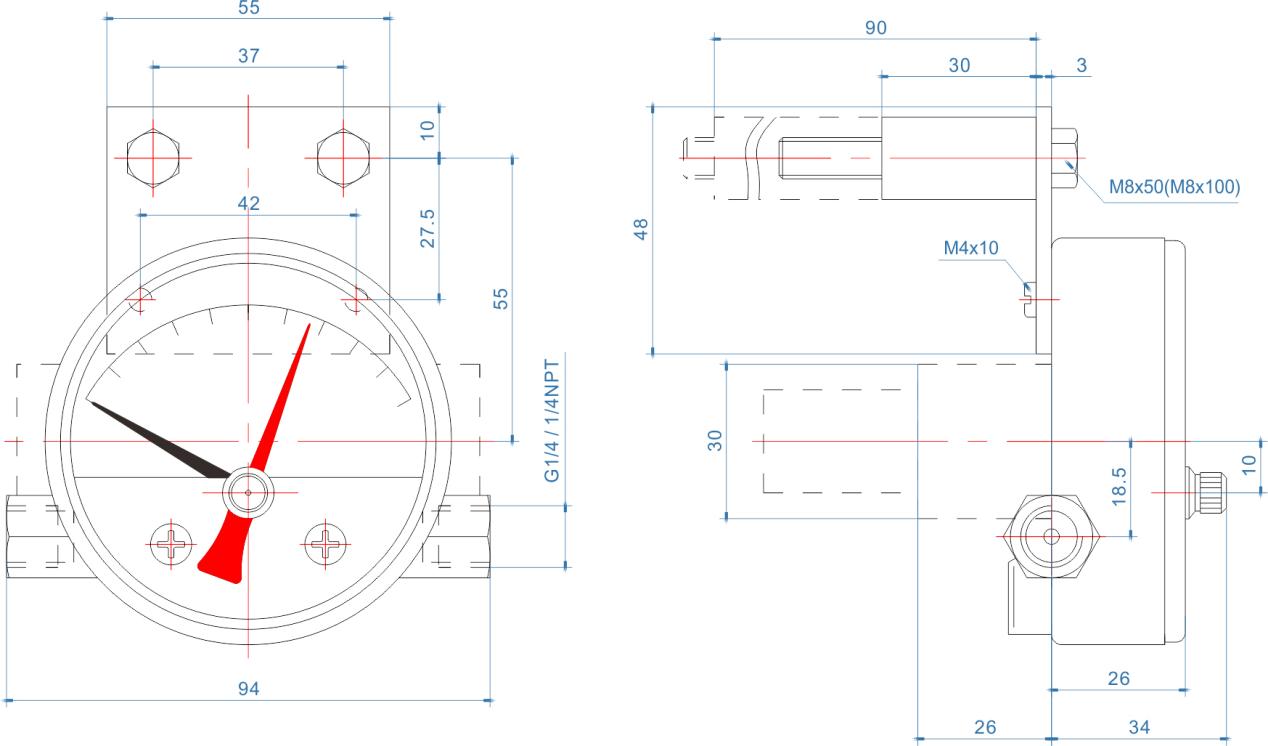

Understanding Pressure Gauges

Every CO2 fire extinguisher comes equipped with a pressure gauge, which indicates whether the extinguisher is charged and ready for use. The gauge typically displays the pressure as either 'charged' (green zone) or 'discharged' (red zone). A properly functioning pressure gauge ensures that the extinguisher will deploy the CO2 effectively during an emergency.

How Pressure Gauges Work

Pressure gauges measure the pressure of the carbon dioxide gas stored within the extinguisher’s cylinder. As CO2 is stored in a liquid state under high pressure, the gauge indicates this pressure in pounds per square inch (PSI) or bar. When the extinguisher is activated, the pressure decreases as the gas is released, which will visibly change the gauge reading.

It is crucial to regularly check the pressure gauge to ensure it remains in the green zone. If the needle points to the red zone, this indicates a problem — either the extinguishing agent has been used, or there is a leak in the system. In either case, it is vital to service or replace the extinguisher immediately.

carbon dioxide fire extinguisher pressure gauge factory

Regular Maintenance and Inspection

Maintaining a CO2 fire extinguisher, including regular pressure gauge inspections, is imperative. Under the National Fire Protection Association (NFPA) guidelines, fire extinguishers should be subjected to an annual maintenance check, which includes

1. Visual Inspection Ensure the extinguisher is easily accessible, properly mounted, and free from any obstructions. The pressure gauge should show a reading in the green zone.

2. Physical Condition Inspect the extinguisher for any signs of physical damage, corrosion, or wear. Pay particular attention to the hose and nozzle, as these components can also hinder performance during an emergency.

3. Functional Testing Although CO2 extinguishers do not require frequent functional testing like other types, it’s best practice to follow the manufacturer’s recommendations concerning pressure testing and periodic recharges.

4. Record Keeping Maintain detailed records of inspections and maintenance performed on the fire extinguishers. These records can be crucial in ensuring compliance with local fire codes.

Conclusion

The pressure gauge on a carbon dioxide fire extinguisher plays a critical role in fire safety. Without a properly functioning gauge, the extinguisher may not operate effectively when it is needed most. Regular inspections and maintenance of fire extinguishers are crucial for ensuring both personal safety and the safety of property. By taking the time to understand and monitor the pressure gauge, we can ensure that our fire extinguishers are always prepared for service, providing peace of mind in potentially hazardous situations.

In a world where fire hazards are ever-present, ensuring the readiness and reliability of fire safety equipment is not just a regulatory requirement; it is a moral obligation towards safeguarding lives and property.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025