Nov . 07, 2024 22:54 Back to list

Capillary Diaphragm Seal Pressure Gauges Suppliers and Exporters Worldwide

Understanding Capillary Diaphragm Seal Pressure Gauges and Their Export Market

In the realm of industrial instrumentation, pressure measurement is critical for ensuring the safe and efficient operation of various processes. Among the many types of pressure measurement devices available, capillary diaphragm seal pressure gauges stand out due to their unique design and functionality. This article delves into the workings of capillary diaphragm seals, their applications, and the growing export market for these essential instruments.

What is a Capillary Diaphragm Seal Pressure Gauge?

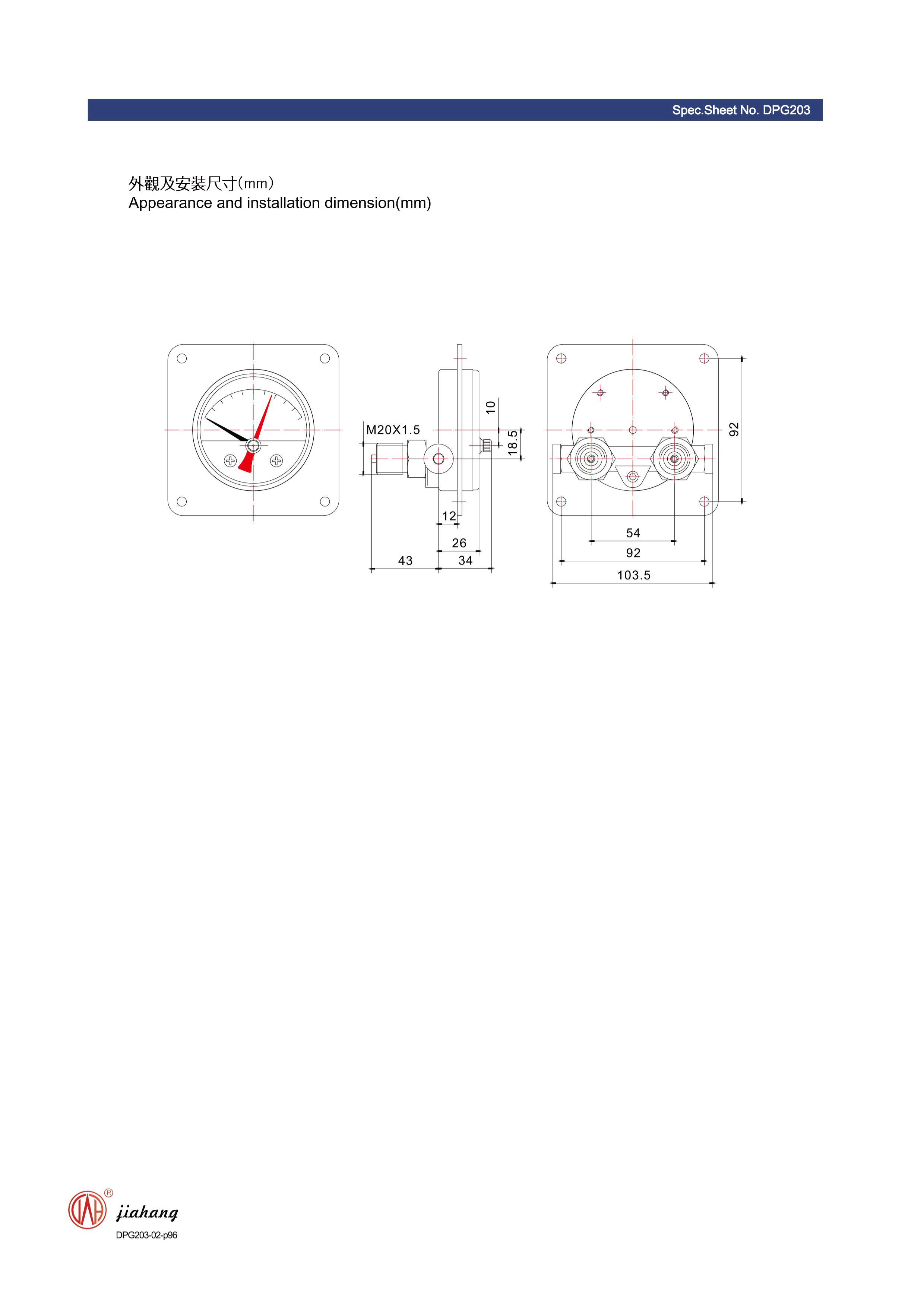

A capillary diaphragm seal pressure gauge consists of two primary components the diaphragm seal and the pressure gauge. The diaphragm seal is a flexible membrane that separates the pressure measuring element from the process medium. The gauge is often connected to a capillary tube that transmits the pressure from the process to the gauge without direct contact with the potentially harmful or corrosive material.

The primary advantage of this design is that it protects the gauge from process-related damage, such as corrosion, clogging, or high temperatures. This makes the capillary diaphragm seal pressure gauge ideal for various challenging applications, including chemical processing, oil and gas, pharmaceuticals, and food and beverage manufacturing.

Key Benefits of Capillary Diaphragm Seal Pressure Gauges

1. Protection Against Corrosive Media The diaphragm seal effectively isolates the gauge from corrosive liquids and gases, extending its lifespan and reliability. 2. Temperature Resistance The design can accommodate harsh temperature conditions, making it suitable for environments where standard gauges would fail.

3. Minimized Pressure Pulsations The capillary tube can buffer pressure spikes and pulsations, providing stable readings.

5. Safety Assurance By isolating the measuring element from hazardous or toxic substances, they help ensure operator safety and compliance with health regulations.

capillary diaphragm seal pressure gauge exporters

Global Demand and Export Opportunities

The global market for pressure measurement devices, particularly capillary diaphragm seal pressure gauges, is experiencing significant growth. Several factors are driving this trend

1. Increased Industrialization As countries industrialize and invest in their manufacturing capabilities, the demand for reliable pressure measurement instruments rises.

2. Regulatory Compliance Many industries are subject to strict regulations requiring accurate pressure measurement for safety and environmental reasons. This necessity is propelling the demand for specialized gauges.

3. Technological Advancements Innovations in materials and technology are leading to the development of more accurate and durable pressure gauges, further boosting their appeal.

4. Growth in Emerging Markets Countries in Asia, Africa, and Latin America are investing heavily in infrastructure and chemical processes, leading to an uptick in demand for all types of pressure measuring devices.

Given these trends, exporters of capillary diaphragm seal pressure gauges are well-positioned to capitalize on the burgeoning market. Companies in manufacturing hubs like Germany, the USA, and China are leaders in this field, leveraging advanced manufacturing processes to produce high-quality, durable gauges.

Conclusion

Capillary diaphragm seal pressure gauges are an essential component of many industrial processes, offering protection, accuracy, and long-term reliability in challenging conditions. As global industrial activity continues to grow, the demand for such instruments is expected to increase, creating robust export opportunities for manufacturers. Those involved in the production and distribution of these gauges must ensure they remain competitive through continuous innovation, adherence to international quality standards, and a strong understanding of regional market needs.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025