Oct . 12, 2024 04:56 Back to list

buy high accuracy differential pressure gauge

Buying High Accuracy Differential Pressure Gauges A Comprehensive Guide

When it comes to measuring differential pressure in various industrial applications, accuracy is paramount. A high accuracy differential pressure gauge ensures reliable readings, which are essential for maintaining optimal performance and safety in systems such as HVAC, process control, and fluid management. This article provides an overview of the key factors to consider when buying a high accuracy differential pressure gauge.

Understanding Differential Pressure Gauges

Differential pressure gauges measure the difference in pressure between two points in a system. This could involve measuring upstream and downstream pressures in a pipeline or monitoring pressure drops across filters. High accuracy gauges are specifically designed to provide precise measurements, often within a very narrow margin of error. This level of precision is crucial in applications where even minor fluctuations can lead to safety hazards or reduced efficiency.

Key Features to Consider

1. Accuracy Ratings When selecting a gauge, check its accuracy rating, typically expressed as a percentage of the full scale. High precision gauges often have accuracy ratings of 0.1% or better. Ensure the gauge you choose fits the specific accuracy requirements of your application.

buy high accuracy differential pressure gauge

2. Measurement Range It’s vital to choose a differential pressure gauge that covers the range you need. Too broad a range can compromise accuracy, while too narrow a range can lead to saturation or damage to the gauge.

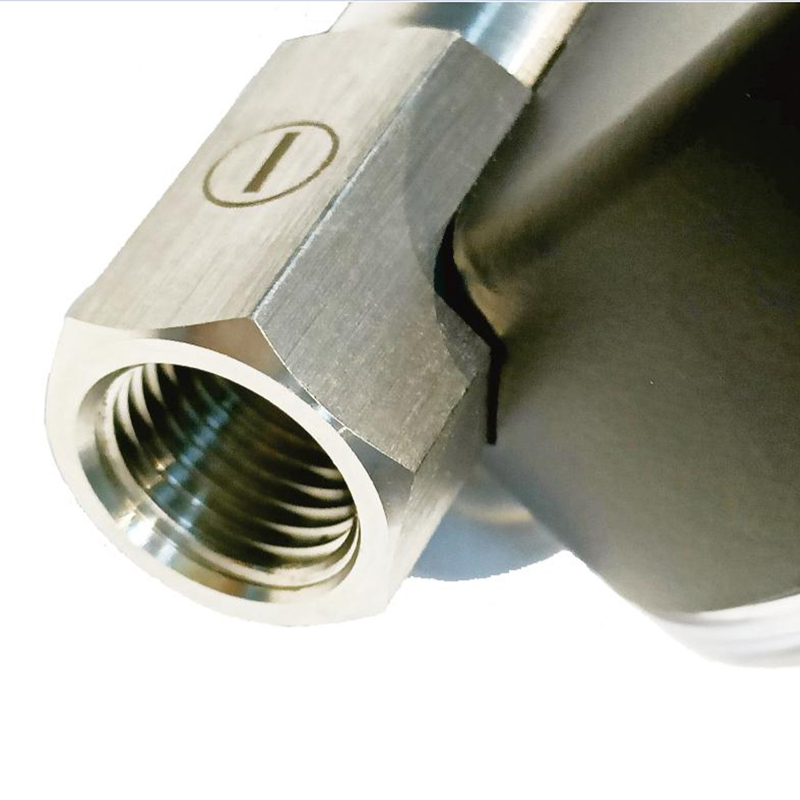

3. Construction and Durability Depending on your application, consider the materials and construction of the gauge. For example, stainless steel housings and chemical-resistant diaphragms are recommended for harsh environments.

4. Calibration and Certification Ensure that the gauge is calibrated and comes with appropriate certification. Calibration ensures that the readings are precise and up to industry standards.

5. Type of Gauge Depending on your needs, choose from various types of gauges such as analog, digital, or electronic. Each has its advantages; digital gauges often provide more features like data logging and remote monitoring.

Conclusion

Investing in a high accuracy differential pressure gauge is crucial for any operation that requires precise pressure measurements. By understanding the essential features and considerations, such as accuracy ratings, measurement range, and construction, you can make informed purchasing decisions. This ensures the safety and efficiency of your operations, ultimately leading to better performance and cost savings. Whether you are replacing an old gauge or investing in new technology, choosing the right differential pressure gauge is vital for your success in industrial applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025