Nov . 21, 2024 19:14 Back to list

buy flanged diaphragm pressure gauge

Understanding Flanged Diaphragm Pressure Gauges A Comprehensive Guide

Pressure gauges play a crucial role in various industries, providing essential data for the safe and efficient operation of equipment and processes. Among the numerous types of pressure gauges available, flanged diaphragm pressure gauges stand out due to their unique construction and high reliability. This article delves into the features, benefits, and applications of flanged diaphragm pressure gauges, guiding potential buyers on what to consider when purchasing these instruments.

What is a Flanged Diaphragm Pressure Gauge?

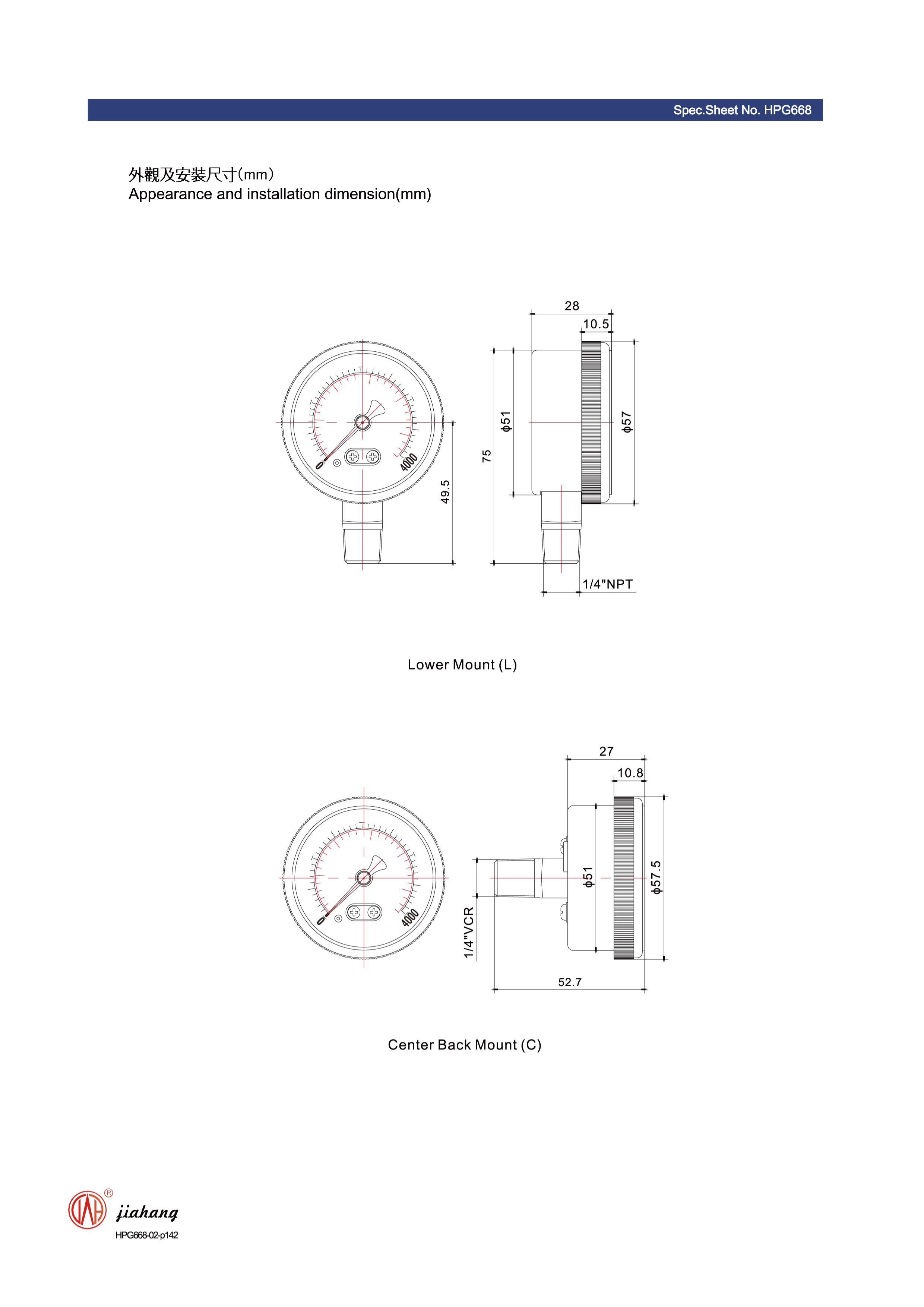

A flanged diaphragm pressure gauge is a type of gauge that utilizes a diaphragm to measure pressure changes accurately. This gauge is equipped with a flange that allows for easy installation and secure mounting within pipelines or pressure vessels. The diaphragm, typically made from stainless steel or other corrosion-resistant materials, flexes in response to pressure changes. This flexing motion is converted into a readable pressure measurement, which is usually displayed on a dial or digital screen.

Key Features

1. Robust Design Flanged diaphragm pressure gauges are built to withstand harsh operating conditions. Their design minimizes the risk of corrosion and damage, making them suitable for aggressive media and high-pressure environments.

2. Flanged Connection The flanged connection allows for easy installation and maintenance. It provides a secure and leak-proof seal, essential for monitoring high-pressure fluids and gases in pipelines.

3. Accuracy These gauges provide high accuracy in pressure measurement, essential for processes where precision is critical. They can measure a wide range of pressures, from vacuum to ultra-high pressure applications.

4. Wide Range of Applications Flanged diaphragm pressure gauges are versatile and can be used in various applications, including chemical processing, oil and gas, power generation, and food processing.

5. Customization Options Many manufacturers offer options for customization, including different diaphragm materials, pressure ranges, and connection sizes, allowing buyers to select a gauge that suits their specific requirements.

Benefits of Using Flanged Diaphragm Pressure Gauges

buy flanged diaphragm pressure gauge

2. High Sensitivity The design of the diaphragm allows for high sensitivity, enabling accurate measurements even with small pressure changes.

3. Reduced Maintenance Costs With durable materials and designs, flanged diaphragm pressure gauges typically require less frequent maintenance, leading to cost savings over time.

4. Ease of Installation The flange design simplifies the installation process, making it easier for technicians to mount and replace gauges without complex procedures.

How to Choose the Right Flanged Diaphragm Pressure Gauge

When considering the purchase of a flanged diaphragm pressure gauge, there are several factors to keep in mind

1. Pressure Range Determine the range of pressures you need to measure. Opt for a gauge that can comfortably handle your maximum expected pressure.

2. Material Compatibility Ensure that the materials used in the diaphragm and the housing are compatible with the media being measured, especially in corrosive or high-temperature environments.

3. Size and Connection Type Take into account the size of the flange and the connection type required. Standardization can simplify installation.

4. Calibration and Accuracy Review the accuracy specifications and check if the gauge comes calibrated from the manufacturer or requires field calibration.

5. Manufacturer Reputation Choose gauges from reputable manufacturers known for quality and reliability. It’s also beneficial to consider warranties and customer service support.

Conclusion

Flanged diaphragm pressure gauges are invaluable instruments for accurately monitoring pressure in diverse industrial applications. They offer robust performance, ease of installation, and high accuracy. When selecting a pressure gauge, consider your specific operational requirements to ensure you find the best fit for your needs. Investing in a quality flanged diaphragm pressure gauge will enhance your system’s reliability and safety, making it a worthy addition to any industrial setup.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025