Dec . 20, 2024 21:07 Back to list

Choosing an In-Line Differential Pressure Gauge for Improved Measurement Accuracy and Efficiency

Understanding the Importance of a Buy Differential Pressure Gauge in Line

Differential pressure gauges are essential instruments used in various industries to monitor the difference in pressure between two points in a fluid system. Their applications range from HVAC systems to industrial processes, where maintaining optimal performance and safety is critical. In this article, we will explore the significance of investing in a differential pressure gauge for in-line measurements, detailing its functionalities, applications, and the advantages it offers.

What is a Differential Pressure Gauge?

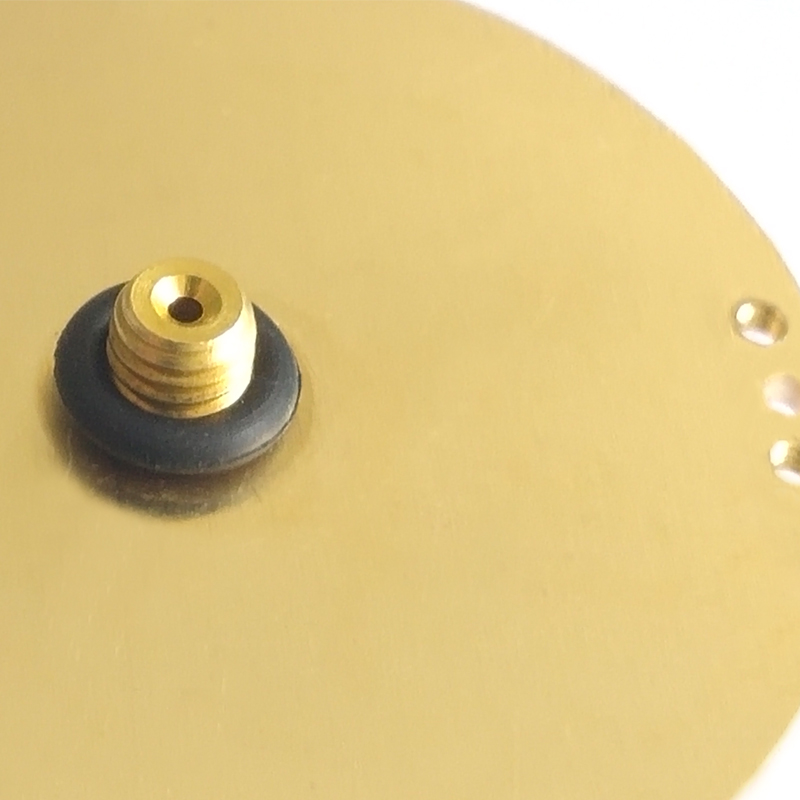

A differential pressure gauge measures the pressure difference between two locations within a system. This measurement is crucial for assessing the performance of filters, pumps, and various equipment. The gauge typically consists of two pressure ports one connected to the high-pressure side and the other to the low-pressure side. The gauge then displays the pressure difference, providing valuable insights into the system's behavior.

Why Invest in a Differential Pressure Gauge?

1. Monitoring System Performance One of the primary reasons to buy a differential pressure gauge is the ability to monitor system performance constantly. In applications like HVAC systems, these gauges help ensure that air filters are not clogged by indicating when they require maintenance. This proactive monitoring prevents inefficient operations and potential system failures.

2. Ensuring Safety Differential pressure gauges play a crucial role in safety management, particularly in industrial settings. By monitoring pressure differentials, operators can detect abnormal conditions that may indicate leaks or blockages in pipes and ducts. Timely identification of such issues can prevent accidents, ensuring the safety of personnel and equipment.

3. Energy Efficiency In many cases, significant pressure drops can lead to increased energy consumption. By utilizing a differential pressure gauge, companies can identify areas of high resistance within their systems. Understanding where energy is being wasted allows for the implementation of corrective measures, ultimately saving money and reducing carbon footprints.

4. Quality Control In manufacturing and processing industries, maintaining the right pressure levels is vital for product quality. A differential pressure gauge provides real-time data that operators can use to make necessary adjustments. This level of control is essential for meeting production standards and ensuring customer satisfaction.

buy differential pressure gauge in line

Applications of Differential Pressure Gauges

The versatility of differential pressure gauges makes them applicable in numerous sectors. Common uses include

- HVAC Systems Monitoring filter conditions and airflow to ensure optimal heating, ventilation, and air conditioning performance. - Fluid and Gas Processing Ensuring consistent flow rates in pipelines and tanks by monitoring pressure differences. - Water Treatment Measuring pressure drops across filters to determine when maintenance or replacement is needed. - Pharmaceuticals Ensuring a controlled environment by maintaining specific pressure differentials during production processes.

Choosing the Right Differential Pressure Gauge

When selecting a differential pressure gauge, several factors must be considered. These include

- Range and Accuracy The gauge's measurement range should match the expected pressure differentials in the system. Accuracy is crucial for reliable data. - Material Compatibility The gauge materials must be compatible with the fluids being measured, especially in corrosive or extreme environments. - Connection Types Ensure that the gauge's connection options fit the existing piping system to facilitate easy installation.

Conclusion

Investing in a quality differential pressure gauge in line is an essential step for businesses that rely on fluid systems. By providing vital information about pressure differences, these gauges not only enhance operational efficiency and safety but also contribute to environmental sustainability. By understanding their significance and selecting the right type for specific applications, industries can ensure smoother processes, reduced risk, and improved product quality. In today’s competitive market, the adoption of such advanced measurement tools is no longer optional; it is a fundamental part of maintaining a successful operation.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025