Nov . 21, 2024 05:23 Back to list

buy differential pressure gauge diaphragm type

Understanding Buy Differential Pressure Gauge Diaphragm Type

In various industrial applications, pressure measurement is crucial for ensuring safe and efficient operations. Among the different types of pressure gauges available, the diaphragm-type differential pressure gauge stands out for its accuracy and reliability. This article explores the importance and functionality of diaphragm-type differential pressure gauges, as well as key factors to consider when buying one.

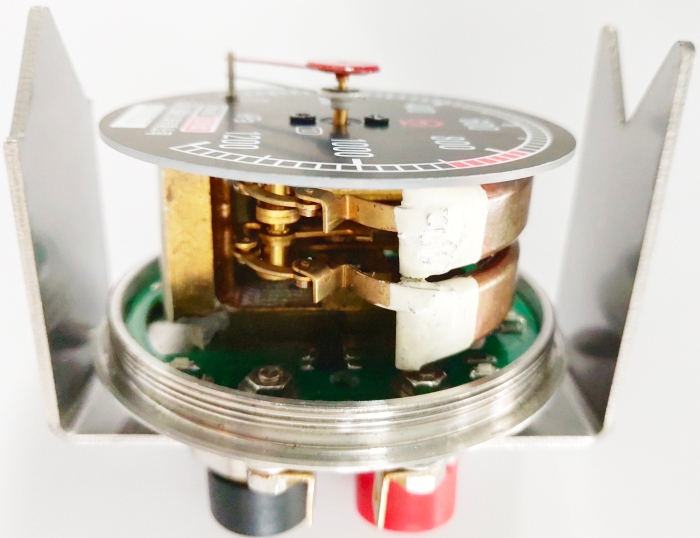

Differential pressure gauges measure the difference in pressure between two points, making them essential in processes such as filtration, flow measurement, and liquid level detection. The diaphragm mechanism allows these gauges to respond to pressure changes effectively. A flexible diaphragm, usually made from materials such as stainless steel or fluoropolymers, separates two chambers. When pressure is applied, the diaphragm bends, causing a movement that can be translated into a readable output on the gauge.

When considering the purchase of a diaphragm-type differential pressure gauge, accuracy is a primary factor. It's vital to choose a gauge that can provide precise measurements relevant to your specific application. Check the manufacturer's specifications for the device's accuracy rating, typically expressed as a percentage of the full scale. For critical processes, investing in a high-accuracy gauge ensures better control and minimizes risks.

buy differential pressure gauge diaphragm type

Another essential aspect is the gauge’s pressure range. Different applications require different ranges of pressure measurements. Understanding the pressure requirements of your system is crucial for selecting the right gauge. Additionally, consider the gauge's temperature rating, as extreme temperatures can impact the performance and longevity of the gauge.

Material compatibility is also important to ensure the gauge withstands the conditions of your environment. For instance, the presence of corrosive substances or extreme temperatures may necessitate specific materials for both the diaphragm and the casing. Always consult with the manufacturer or a knowledgeable supplier to ensure the chosen materials will perform well in your application.

Finally, installation and maintenance ease should also influence your decision. Look for gauges designed for straightforward installation and those that require minimal maintenance to keep downtime to a minimum.

In conclusion, the diaphragm-type differential pressure gauge is a vital tool for effective pressure monitoring in various industries. By considering factors such as accuracy, pressure range, material compatibility, and maintenance, you can make an informed decision and invest in a reliable gauge that meets your operational needs.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025