Sep . 03, 2024 04:46 Back to list

buy micro type differential pressure gauge

Understanding Micro Type Differential Pressure Gauges

In various industries, precision and accuracy are paramount, especially when it comes to monitoring and controlling pressure levels. One essential tool that plays a significant role in this process is the micro type differential pressure gauge. This instrument is designed to measure the difference in pressure between two points, offering valuable insights for various applications ranging from HVAC systems to cleanroom environments.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the pressure difference between two locations. In simple terms, it consists of two pressure sensing ports one for the high-pressure side and another for the low-pressure side. The gauge displays the difference in pressure, which can be crucial for maintaining optimal conditions in a system. For instance, in HVAC applications, it helps in monitoring filter performance and ensuring efficient airflow.

Features of Micro Type Differential Pressure Gauges

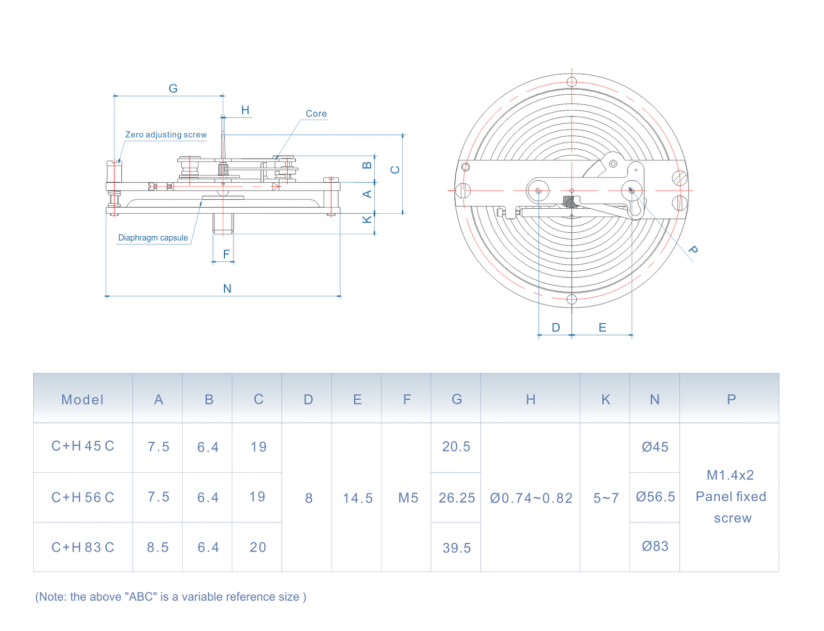

Micro type differential pressure gauges are specifically designed for applications where space is a constraint but precision remains a priority. These gauges are typically smaller and more compact than traditional designs, making them ideal for installation in tight environments. Despite their small size, they feature advanced technology that ensures accurate readings and reliable performance.

1. High Precision Micro type differential pressure gauges often come with high-resolution displays, providing users with clear and precise measurements of pressure differences.

2. Compact Design The smaller form factor of these gauges allows for installation in confined spaces, making them suitable for a variety of applications, including laboratories, cleanrooms, and other sensitive environments.

buy micro type differential pressure gauge

4. Wide Measuring Range Even in their compact form, these gauges can measure a wide range of differential pressures, catering to various industrial needs.

Applications

Micro type differential pressure gauges find applications in numerous industries, including

- Pharmaceuticals Ensuring that cleanroom environments maintain the required pressure differentials to prevent contamination. - HVAC Monitoring air filter pressure drops to optimize system performance and energy efficiency. - Food and Beverage Managing pressure differences in processes that require stringent hygiene and safety standards.

Buying Considerations

When purchasing a micro type differential pressure gauge, it’s essential to consider factors like accuracy, range, and compatibility with your existing systems. Additionally, assessing the gauge's certification and compliance with industry standards can ensure that you select a reliable device.

Conclusion

In summary, micro type differential pressure gauges are invaluable tools that enhance monitoring and control in various industrial applications. Their compactness, precision, and versatility make them favorable choices for environments where space is limited but accuracy is crucial. By investing in a quality differential pressure gauge, businesses can ensure optimal performance, compliance, and operational efficiency. As industries continue to evolve, these gauges will remain instrumental in the accurate assessment of pressure differentials across diverse applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025