Sep . 07, 2024 22:13 Back to list

Buy Customized Diaphragm Seal Pressure Gauge - Precision Instruments for Reliable Measurements

The Importance of Buying Customized Diaphragm Seal Pressure Gauges

When it comes to measuring pressure in various industrial applications, precision is key. Among the various types of pressure gauges available, diaphragm seal pressure gauges have emerged as a popular choice for many industries. These gauges provide accurate readings while protecting sensitive measuring components from harsh environments. However, the need for customization should not be overlooked. In this article, we explore the benefits of buying customized diaphragm seal pressure gauges.

What is a Diaphragm Seal Pressure Gauge?

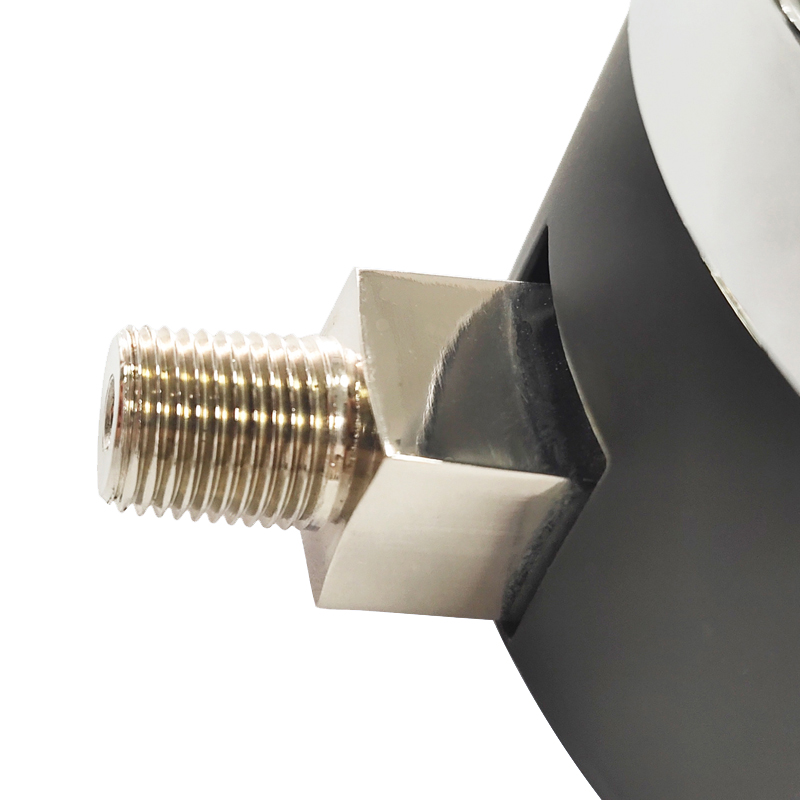

Diaphragm seal pressure gauges consist of a pressure sensing element (usually a diaphragm) which separates the process fluid from the measuring instrument. This design is particularly useful for applications involving high temperatures, corrosive substances, or viscous fluids, as it prevents these elements from contaminating the gauge and affecting accuracy. By isolating the measurement system, diaphragm seal gauges can enhance durability, ensuring longevity and reliable performance.

Why Opt for Customization?

1. Tailored Fit for Specific Applications Every industry has its unique set of conditions and requirements. Buying customized diaphragm seal pressure gauges means you can get a product designed specifically for your application. Whether you need to measure the pressure of a corrosive chemical or a high-temperature gas, customization ensures that the materials and design align perfectly with the operational demands.

buy customized diaphragm seal pressure gauge

2. Enhanced Accuracy and Performance Standard diaphragm seal gauges might not provide the precision required in specialized applications. Customized gauges can be engineered to minimize error and maximize performance, allowing for more accurate readings. This is particularly crucial in industries such as pharmaceuticals or petrochemicals, where precise measurements are essential for safety and compliance.

3. Improved Resistance to Environmental Factors Customized gauges can be designed to withstand specific environmental factors such as extreme temperatures, vibrations, or pressures that standard models may not endure. By considering these factors upfront, you can ensure that your pressure gauge operates reliably over its intended lifespan.

4. Compatibility with Existing Systems In many cases, industrial plants and facilities have existing systems and equipment in place. Customized diaphragm seal pressure gauges can be made to fit seamlessly with these existing setups, thereby reducing installation complications and maintenance costs.

5. Cost-Effectiveness in the Long Run While custom products may carry a higher initial price, their durability, accuracy, and suitability can lead to lower repair and replacement costs over time. Investing in a quality, customized pressure gauge can alleviate operational downtime and enhance overall productivity.

Conclusion

In summary, the advantages of purchasing customized diaphragm seal pressure gauges cannot be overstated. They offer tailored solutions that meet the specific demands of various industries and applications. Investing in customized gauges not only enhances measurement accuracy but also promotes longevity and compatibility within existing systems. Whether you are in the pharmaceutical, food, or chemical industry, considering customized diaphragm seal pressure gauges could be one of the best decisions for your operational efficiency and success.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025