Oct . 22, 2024 10:05 Back to list

Budenberg Diaphragm Seal Pressure Gauge Maintenance and Service Solutions

Understanding the Budenberg Diaphragm Seal Pressure Gauge A Guide to Service and Maintenance

In the world of industrial measurement and monitoring, precision is paramount. One of the critical components in this realm is the diaphragm seal pressure gauge, a device favored for its durability and ability to handle harsh environments. Manufacturers such as Budenberg have established a notable reputation in this field, known for their high-quality pressure gauges equipped with diaphragm seals. In this article, we will explore the functionality, advantages, and essential service practices of Budenberg diaphragm seal pressure gauges.

What is a Diaphragm Seal Pressure Gauge?

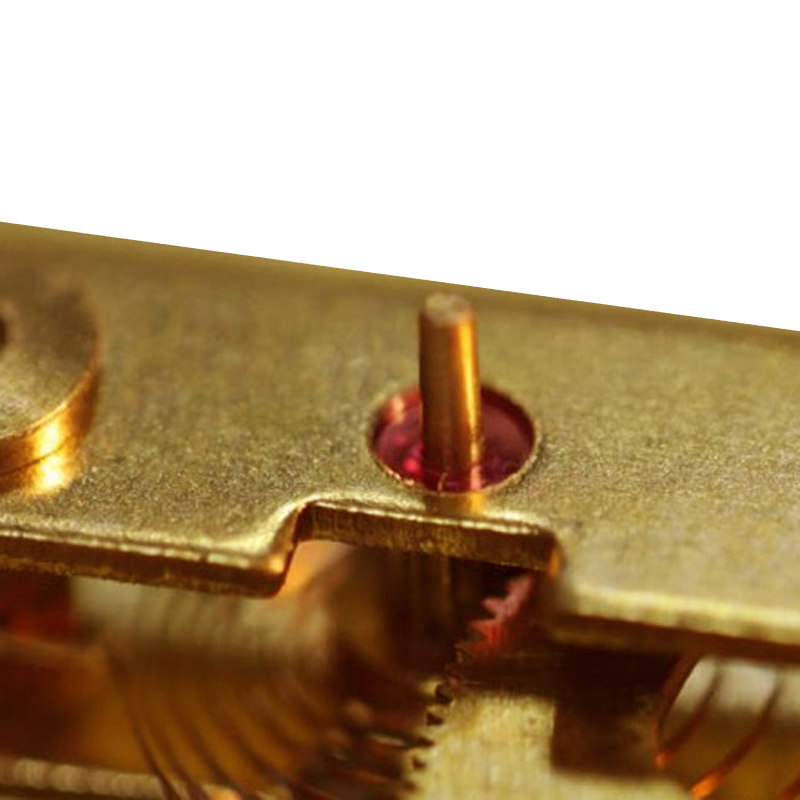

A diaphragm seal pressure gauge consists of a Bourdon tube pressure gauge coupled with a diaphragm seal. The diaphragm seal is essentially a barrier that prevents process media from entering the gauge. This design is particularly beneficial in environments where the process media is corrosive, viscous, or contains solid particles that could damage the gauge internals. By isolating the measuring instrument from the process fluid, the diaphragm seal ensures accurate readings and prolongs the lifespan of the gauge.

Advantages of Budenberg Diaphragm Seal Pressure Gauges

Budenberg diaphragm seal pressure gauges offer several advantages, making them a preferred choice in many industrial applications

1. Corrosion Resistance With materials that can withstand aggressive chemicals and high temperatures, Budenberg gauges are ideal for use in chemical processing industries.

2. Low Maintenance The robust design of diaphragm seals minimizes wear and tear, reducing the need for frequent maintenance. This is crucial in environments where downtime can be costly.

3. Accurate Readings The isolation mechanism not only protects the gauge but also ensures that the readings are accurate, even in fluctuating process conditions.

budenberg diaphragm seal pressure gauge service

Service and Maintenance of Budenberg Diaphragm Seal Pressure Gauges

To keep a Budenberg diaphragm seal pressure gauge functioning optimally, regular service and maintenance are essential. Here are some service tips to consider

1. Routine Inspections Regularly inspect the gauge for any signs of damage or corrosion. Look for leaks around the diaphragm seal and ensure that the casing is intact.

2. Calibration Periodically calibrate the pressure gauge to ensure its readings remain accurate. Budenberg typically provides guidelines for calibration intervals based on the specific application and environment.

3. Cleaning If the diaphragm seal has been exposed to process media, ensure it is cleaned according to the manufacturer's specifications. This is particularly important for viscous or sticky substances that can affect the performance of the gauge.

4. Record Keeping Maintain detailed records of inspections, maintenance, and calibration activities. This documentation can help in identifying patterns or recurring issues, aiding in predictive maintenance strategies.

5. Consulting Manufacturers For any repairs or replacements, consult Budenberg or authorized service centers. They can provide valuable support and ensure that any replacement parts meet the original specifications for quality and performance.

Conclusion

Budenberg diaphragm seal pressure gauges are an indispensable tool in various industries, providing reliable and accurate measurements under challenging conditions. Understanding how these gauges work and implementing proper service and maintenance protocols can significantly enhance their performance and longevity. For industries that prioritize precision and durability, investing in Budenberg products and adhering to recommended service practices is a decision that pays off in operational efficiency and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025