Oct . 06, 2024 19:18 Back to list

best precision pressure gauges india

Best Precision Pressure Gauges in India A Comprehensive Overview

Precision pressure gauges play a critical role in various industrial applications, ensuring accurate measurement and monitoring of pressure in fluids and gases. In India, the demand for high-quality precision pressure gauges has surged, driven by the growth of industries such as manufacturing, oil and gas, pharmaceuticals, and food processing. This article aims to highlight some of the best precision pressure gauges available in India, focusing on their features, applications, and the factors to consider when selecting the right one.

Importance of Precision Pressure Gauges

Precision pressure gauges are essential for various reasons. They help maintain safety standards by ensuring that the pressure levels in systems do not exceed safe limits, thus preventing potential accidents. Additionally, accurate measurements enhance process control, leading to improved efficiency and reduced operational costs. In industries like pharmaceuticals, where processes must meet stringent regulatory standards, precision pressure gauges are critical for maintaining product quality and safety.

Types of Precision Pressure Gauges

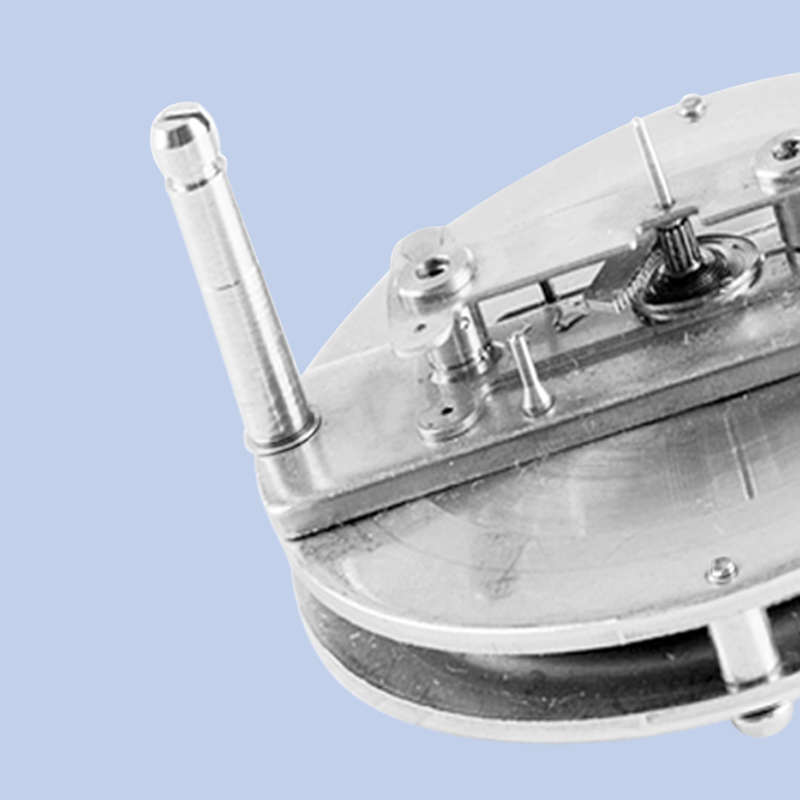

1. Bourdon Tube Pressure Gauges These are the most common types of mechanical pressure gauges, widely used for their simplicity and reliability. They operate on the principle of a Bourdon tube, which deforms under pressure and drives a pointer on a dial to indicate the pressure level. These gauges are available in various sizes and pressure ranges, making them suitable for numerous applications.

2. Digital Pressure Gauges Increasingly popular due to their accuracy and ease of use, digital pressure gauges employ electronic sensors to provide precise measurements. They often feature digital displays, which offer clear readings and can include additional functionalities such as data logging, alarms, and connectivity options for integration into automated systems.

3. Capacitive Pressure Gauges Used primarily in applications that require high accuracy, capacitive gauges detect pressure through changes in capacitance caused by the deformation of a diaphragm under pressure. These gauges are suitable for laboratory and research environments where precise measurements are crucial.

4. Piezoelectric Pressure Gauges These gauges are well-suited for dynamic pressure measurements, such as in hydraulic systems or during impact testing. They use piezoelectric materials that generate an electrical charge in response to applied pressure, allowing for rapid and accurate readings.

Top Brands and Models in India

best precision pressure gauges india

Several brands are recognized for their quality pressure gauges in India. Here are a few notable mentions

1. Ashcroft Known for its exceptional engineering, Ashcroft offers a variety of Bourdon tube and digital pressure gauges suitable for industrial applications. Their products are known for durability and accuracy.

2. WIKA A global leader in pressure measurement technology, WIKA provides an extensive range of pressure gauges, including mechanical and electronic options. Their gauges are often praised for their robustness and precision.

3. Sensonics This Indian brand specializes in manufacturing high-quality pressure gauges tailored for specific industrial needs. They offer both analog and digital gauges that meet international standards.

4. Omega Engineering Omega is renowned for its innovative measurement solutions. Their pressure gauges are equipped with advanced features like USB connectivity and data logging capabilities, making them a popular choice for tech-savvy industries.

Factors to Consider When Choosing Precision Pressure Gauges

When selecting a precision pressure gauge, several factors should be considered to ensure optimal performance

- Accuracy Look for gauges with high accuracy specifications, typically expressed as a percentage of full-scale reading. - Range Ensure the gauge can measure the pressure range relevant to your application. - Medium Compatibility Check if the materials of the gauge are compatible with the fluids or gases being measured to prevent corrosion or damage. - Environmental Conditions Consider the operational environment—temperature, humidity, and potential exposure to harsh conditions can affect the gauge's performance. - Calibration and Maintenance Choose gauges that are easy to calibrate and maintain to ensure long-term reliability and accuracy.

Conclusion

The market for precision pressure gauges in India is diverse, with numerous options available to suit various industrial needs. By understanding the types of gauges, recognizing trusted brands, and considering critical selection factors, businesses can make informed choices that enhance operational efficiency and safety. As industries continue to evolve, the demand for precise measurement tools will remain paramount, making high-quality pressure gauges an indispensable component of modern industrial processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025