Dec . 03, 2024 21:55 Back to list

best flanged diaphragm pressure gauge

The Best Flanged Diaphragm Pressure Gauge A Comprehensive Guide

In the world of industrial instrumentation, accuracy and reliability are paramount. One of the most critical components in measuring pressure is the diaphragm pressure gauge, particularly the flanged type. This article aims to provide an overview of the best flanged diaphragm pressure gauges, highlighting their features, applications, and benefits.

Understanding Flanged Diaphragm Pressure Gauges

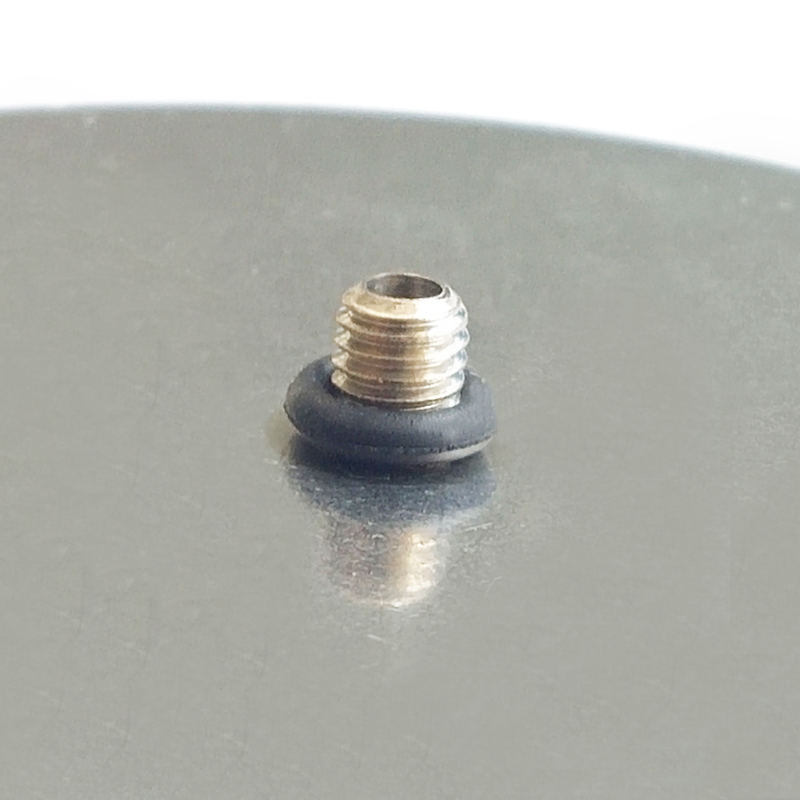

A flanged diaphragm pressure gauge is a device that utilizes a flexible membrane, known as a diaphragm, to convert pressure changes in fluids or gases into a mechanical displacement, which is then translated into a readable pressure measurement. The flanged design allows for easy installation and secure connection to pipelines, making it a preferred choice in many industrial applications.

Key Features of Flanged Diaphragm Pressure Gauges

1. Material Construction The materials used in the construction of diaphragm gauges are critical for their performance and durability. Common materials include stainless steel, which offers excellent corrosion resistance, and special alloys designed to withstand harsh environments.

2. Pressure Ranges Flanged diaphragm pressure gauges come in various pressure ranges, suitable for different applications—from vacuum pressure to high-pressure systems. The choice of pressure range depends on the specific requirements of the process they monitor.

3. Size and Flange Standardization These gauges often adhere to standard flange sizes such as ANSI, DIN, or JIS, which facilitates their integration into existing piping systems. The correct size and standardization ensure optimal performance and minimize leakage risks.

4. Accuracy and Calibration Accuracy is crucial in pressure measurement. High-quality flanged diaphragm gauges provide precision within a specified range, often with a stated accuracy class. Regular calibration helps maintain this accuracy over time.

5. Temperature Resistance In many applications, the operational temperature can vary significantly. Choosing a diaphragm gauge that can withstand temperature fluctuations is essential, especially in processes involving steam or hot liquids.

Applications of Flanged Diaphragm Pressure Gauges

Flanged diaphragm pressure gauges are utilized across various industries due to their versatility and reliability

. Some common applications includebest flanged diaphragm pressure gauge

- Chemical Processing These gauges help monitor pressures in reactors, pipelines, and pumps, ensuring safety and optimal operation.

- Oil and Gas Industry In this sector, accurate pressure measurement is critical for drilling operations, refining, and distribution processes.

- Food and Beverage Hygiene and accuracy are essential in this industry. Flanged diaphragm pressure gauges are often used in brewing processes and other food manufacturing applications to maintain quality control.

- Water Treatment Monitoring pressure in filtration and treatment processes ensures the efficient operation of water systems.

Benefits of Using Flanged Diaphragm Pressure Gauges

1. Enhanced Safety By providing accurate pressure readings, these gauges help prevent overpressure situations that could lead to equipment failure or hazardous conditions.

2. Durability Constructed to withstand harsh environments, flanged diaphragm pressure gauges have a long service life, reducing the need for frequent replacements.

3. Versatility Their ability to gauge a wide range of pressures and compatibility with various fluids makes these devices suitable for diverse industrial applications.

4. Ease of Maintenance The design of these pressure gauges allows for straightforward maintenance and calibration, ensuring they continue to operate effectively.

Conclusion

When selecting the best flanged diaphragm pressure gauge for your application, consider the specific requirements, such as pressure range, material compatibility, and environmental factors. By investing in a high-quality gauge, you can enhance the safety and efficiency of your operations. With their robust construction and reliable performance, flanged diaphragm pressure gauges are an invaluable tool in any industrial setting, ensuring accurate pressure measurements and contributing to better decision-making in process management.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025