Nov . 17, 2024 23:13 Back to list

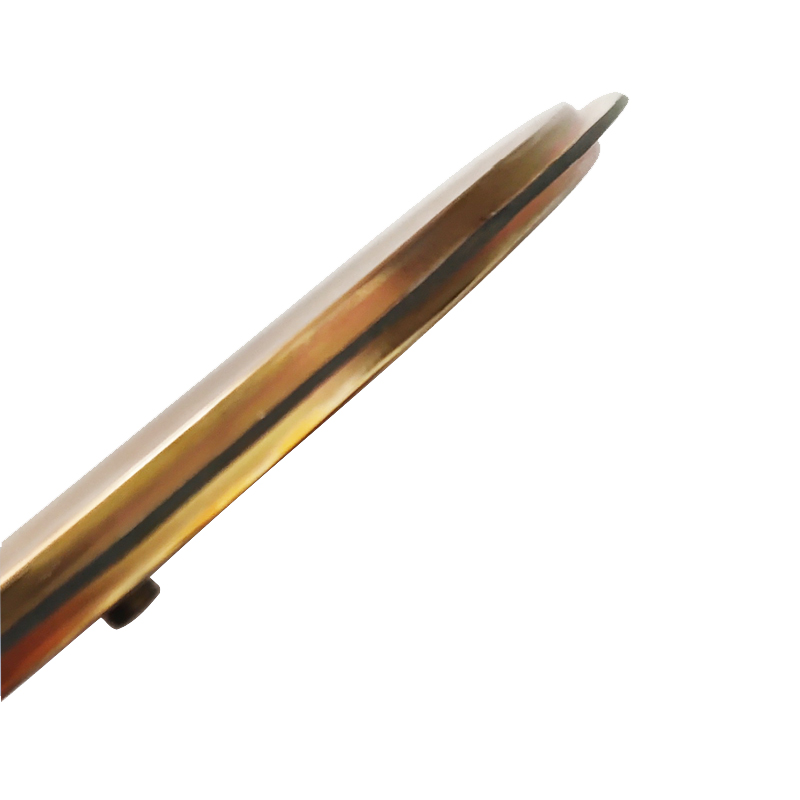

best dry chemical fire extinguisher pressure gauge

Understanding the Importance of the Pressure Gauge in Dry Chemical Fire Extinguishers

When it comes to fire safety, having the right equipment and ensuring its proper functionality can make all the difference. Among the various types of fire extinguishers, dry chemical fire extinguishers are widely recognized for their effectiveness against a range of fires, particularly Class A, B, and C fires. One crucial component of these extinguishers is the pressure gauge, which plays an indispensable role in the overall reliability and performance of the device.

What is a Dry Chemical Fire Extinguisher?

A dry chemical fire extinguisher contains a dry chemical agent, typically either monoammonium phosphate or sodium bicarbonate. These agents work by interrupting the combustion process and can extinguish fires caused by ordinary combustibles, flammable liquids, and electrical equipment. Featuring a nozzle and a pressure gauge, these extinguishers are designed to be easy to use and highly effective.

The Role of the Pressure Gauge

The pressure gauge on a dry chemical fire extinguisher indicates whether the unit is properly charged and ready for use. It typically features a color-coded dial, with a green zone indicating that the extinguisher is fully charged, a red zone indicating overpressure or underpressure, and sometimes a yellow zone representing a caution area. This visual representation is critical for quick assessment in emergency situations where every second counts.

Why is a Functional Pressure Gauge Essential?

1. Readiness for Use The foremost reason to check the pressure gauge regularly is to ensure that the extinguisher is ready to operate at a moment's notice. If the gauge indicates that the pressure is too low or too high, the extinguisher may not work effectively or could potentially fail altogether. Regular maintenance and inspections of the pressure gauge can help identify potential issues long before an emergency arises.

best dry chemical fire extinguisher pressure gauge

2. Safety Compliance Many regulatory standards and safety codes require businesses and homeowners alike to maintain operational fire extinguishers, including checking the pressure gauges. Regular inspections not only safeguard people and property but also ensure compliance with local fire codes and insurance requirements.

3. User Confidence Having a functioning pressure gauge instills confidence in users. In high-pressure situations, knowing that your equipment is reliable can make a significant difference in calmly executing remedial actions against a fire.

Maintenance Tips for the Pressure Gauge

Proper maintenance of your dry chemical fire extinguisher and its pressure gauge is essential for its longevity and efficacy. Here are some maintenance tips

- Regular Inspections Check the pressure gauge monthly. If it’s not in the green zone, replace or service the extinguisher immediately. - Professional Servicing Fire extinguishers should undergo professional servicing at least once a year. Technicians can ensure that all components, including the pressure gauge, are functioning adequately. - Keep it Accessible Ensure that extinguishers are kept in known and easily accessible locations. If a fire starts, you won't have time to search for your equipment.

Conclusion

In summary, the pressure gauge of a dry chemical fire extinguisher is more than just a dial; it is a vital component that ensures the extinguisher is ready for use when needed. With the ability to combat various types of fires, a functioning fire extinguisher can be the difference between a small containment of flames and a disastrous fire outbreak. By regularly checking the pressure gauge and ensuring that it is within the safe operating range, individuals and businesses can maintain a higher level of safety and preparedness. The investment in understanding and maintaining fire extinguishers ultimately contributes to a safer environment for everyone.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025