Nov . 19, 2024 13:44 Back to list

best differential pressure gauge types

Best Differential Pressure Gauge Types A Comprehensive Guide

Differential pressure gauges are critical instruments in various industries, including oil and gas, water and wastewater management, pharmaceuticals, and HVAC systems. These gauges measure the difference in pressure between two points, providing valuable information for monitoring system performance, ensuring safety, and optimizing processes. With numerous types available, selecting the best differential pressure gauge for your application can significantly impact operational efficiency and safety. In this article, we will explore the various types of differential pressure gauges, their advantages, and considerations for choosing the right one.

Types of Differential Pressure Gauges

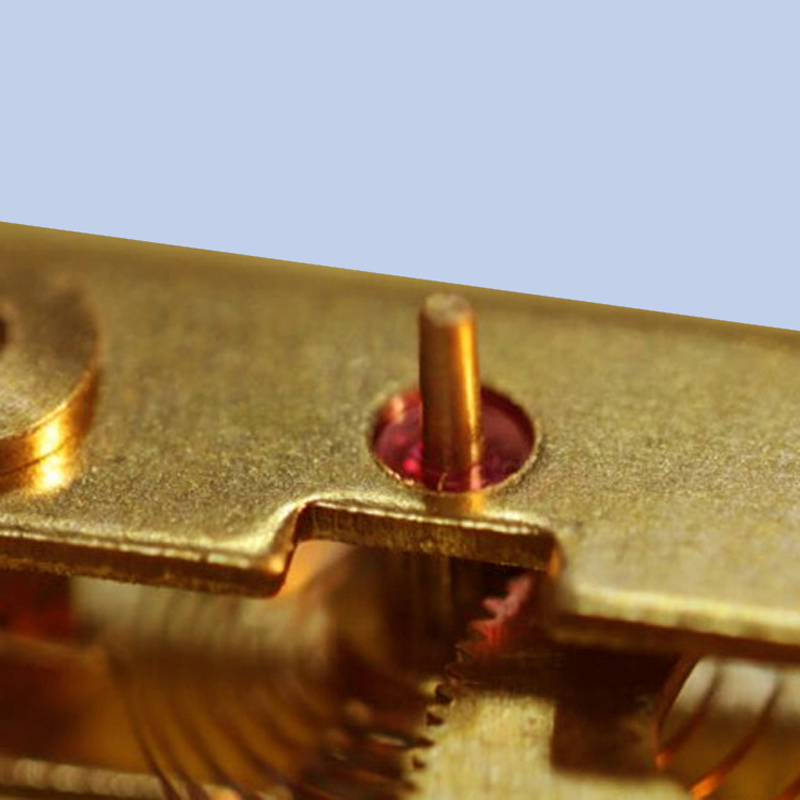

1. Mechanical Differential Pressure Gauges Mechanical differential pressure gauges are the most conventional type, utilizing mechanical components to indicate pressure differences. They often work based on Bourdon tubes, diaphragm sensors, or capsule-type mechanisms. These gauges are simple to use, require minimal maintenance, and are typically cost-effective. However, they might not be as accurate as electronic versions, especially at very low-pressure differentials.

2. Electronic Differential Pressure Gauges Electronic gauges utilize transducers to convert pressure values into electrical signals, offering higher accuracy and advanced features. They can provide digital readings, data logging, and connectivity options for integration with control systems. While they tend to be more expensive than mechanical gauges, their precision and versatility make them ideal for applications requiring stringent monitoring.

3. Capacitive Differential Pressure Gauges Capacitive gauges measure pressure differences by detecting changes in capacitance caused by diaphragm movement. These gauges are highly sensitive and can measure very low differential pressures, making them suitable for applications like cleanroom environments and research laboratories. Their accuracy and quick response time are significant advantages; however, they may be affected by temperature fluctuations and require careful calibration.

4. Piezoelectric Differential Pressure Gauges Utilizing piezoelectric sensors, these gauges can detect rapid changes in pressure and are suitable for dynamic measurement applications. They are often used in aerospace, automotive, and industrial processes where real-time feedback is crucial. However, they may require specialized wiring and signal conditioning, which could complicate installation.

5. Ultrasonic Differential Pressure Gauges This type relies on ultrasonic waves to measure flow rates and pressure differences. Ultrasonic gauges are particularly useful in applications involving gases or aggressive fluids, as they do not have moving parts that could wear out. They offer high accuracy and low maintenance, but their initial setup cost can be significant, and their effective range may be limited.

Considerations for Selecting a Differential Pressure Gauge

best differential pressure gauge types

When selecting a differential pressure gauge, several factors must be considered to ensure optimal performance for your application

- Measurement Range Determine the required measurement range for your specific application

. This will help narrow down the choices, as different types of gauges excel in particular ranges.- Media Compatibility Ensure the selected gauge materials are compatible with the fluids or gases being measured. Corrosive or viscous media may necessitate specific materials or designs.

- Accuracy Requirements Evaluate the tolerance levels for your application. High-precision processes may require electronic or capacitive gauges, while less stringent environments may work well with mechanical gauges.

- Environmental Conditions Consider the operating environment, including temperature fluctuations, pressure extremes, and potential exposure to dust, moisture, or chemicals. Some gauges are designed to withstand harsher conditions than others.

- Installation and Maintenance Think about ease of installation and any ongoing maintenance requirements. Mechanical gauges are usually easier to install and maintain compared to electronic options.

- Budget Lastly, establish a budget for the purchase. While more advanced gauges offer higher accuracy and features, they may also come with a higher price tag.

Conclusion

Differential pressure gauges are vital tools across various industries, providing critical measurements that impact system efficiency and safety. By understanding the different types of gauges available and considering factors specific to your application, you can choose the best differential pressure gauge that meets your needs. Whether you opt for a simple mechanical gauge or a sophisticated electronic version, ensuring proper selection and installation will lead to enhanced performance and reliability in your operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025