Nov . 07, 2024 23:56 Back to list

Optimal Diaphragm Pressure Gauge for Accurate Differential Pressure Measurement

Understanding the Best Differential Pressure Gauge Diaphragm

In various industrial applications, precise measurement of pressure differences is crucial for maintaining operational efficiency and safety. One of the devices that excels in this role is the differential pressure gauge diaphragm. This article will delve into what makes a differential pressure gauge diaphragm effective, its applications, advantages, and considerations for selecting the best one for your needs.

What is a Differential Pressure Gauge Diaphragm?

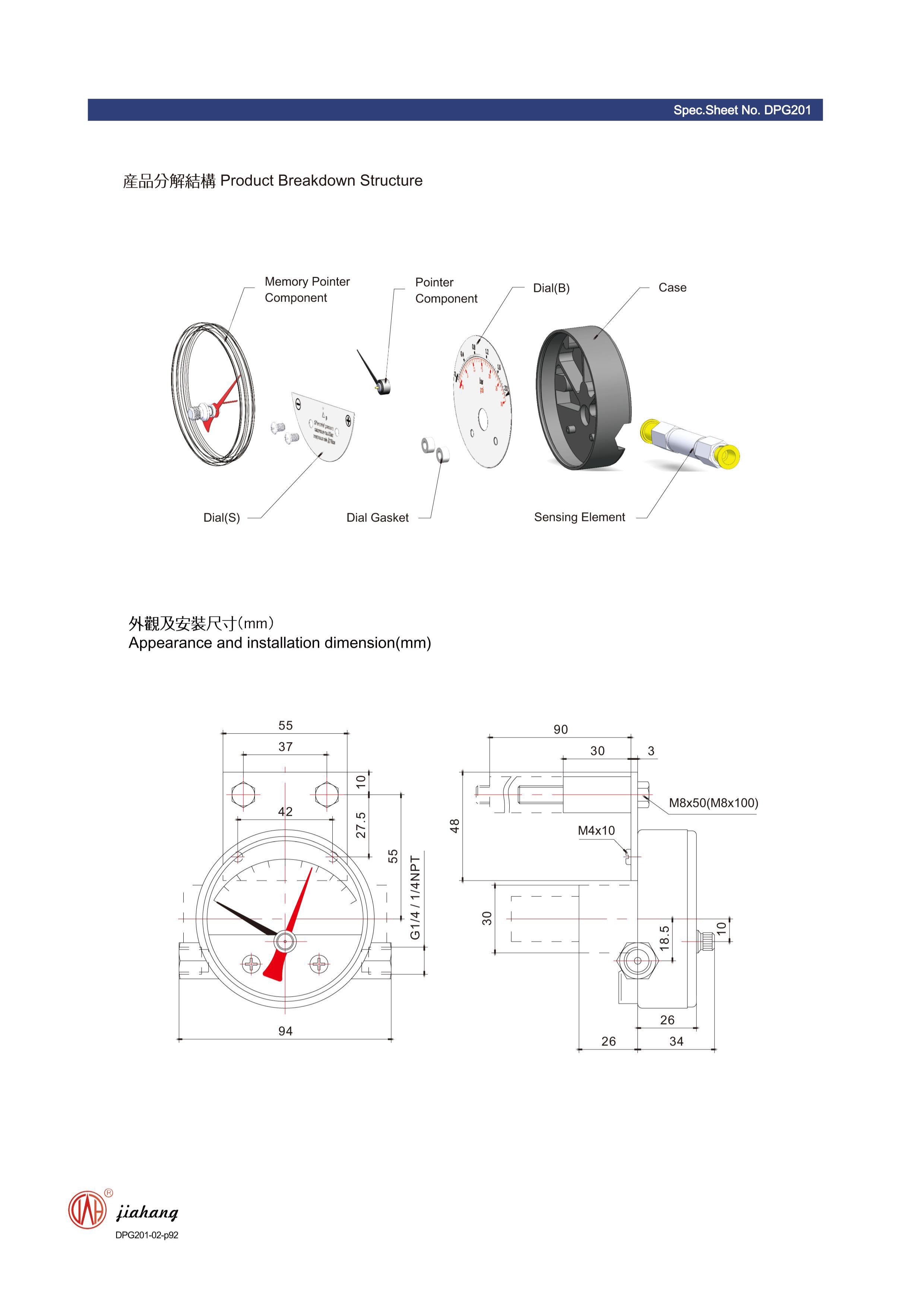

A differential pressure gauge is an instrument that measures the difference in pressure between two points within a system. The diaphragm is a key component of this gauge, typically made from flexible materials designed to deform under pressure. This deformation is translated into a visual reading on a dial or digital display, providing real-time data about the pressure levels.

Key Applications

Differential pressure gauges are used across a range of industries, including

1. Oil and Gas To monitor pressure drops in pipelines and ensure safe operation. 2. HVAC Systems In heating and cooling systems, they help measure filter pressure drops, indicating when maintenance is required. 3. Pharmaceuticals Maintaining the correct differential pressure is vital for clean room environments. 4. Water and Wastewater Treatment They are instrumental in monitoring pressure in filtration systems and ensuring compliance with regulatory standards.

best differential pressure gauge diaphragm

Advantages of Diaphragm-based Gauges

1. Accuracy Diaphragm gauges are known for their accuracy, allowing for reliable measurements which are critical in sensitive environments. 2. Sensitivity They can detect small changes in pressure, making them ideal for applications requiring precise control. 3. Durability High-quality diaphragms made from materials like stainless steel or synthetic composites can withstand harsh conditions, making them suitable for both high and low-pressure environments. 4. Responsive The flexible nature of diaphragms enables quick response times to pressure changes, providing timely information for operators.

Selecting the Best Differential Pressure Gauge Diaphragm

When looking for the best differential pressure gauge diaphragm, several factors make a difference

1. Material Compatibility Ensure that the diaphragm material is compatible with the media it will be measuring. For example, corrosive substances may require a specialized diaphragm. 2. Pressure Range Choose a gauge that can measure the relevant pressure ranges for your application. Gauges are available in different ranges, and using one outside its capability may yield inaccurate results or damage the device. 3. Temperature Ratings Some applications involve extreme temperatures that can affect gauge performance. It’s essential to select a diaphragm that can withstand the operational temperatures without losing accuracy. 4. Size and Installation Consider the space available in your system for installation. Some applications may require compact gauges while others can accommodate larger options. 5. Calibration Options Look for gauges that offer easy calibration procedures to keep measurements accurate over time.

Conclusion

The differential pressure gauge diaphragm is a vital instrument in various industries, ensuring efficient operations and compliance with safety standards. By understanding the advantages of these devices and carefully considering the factors that affect their performance, businesses can select the best options tailored to their specific needs. Investing in high-quality differential pressure gauges is not only a step towards optimizing processes but also a commitment to operational safety and reliability. Whether you're managing an HVAC system, monitoring oil pipelines, or ensuring the integrity of a clean room, the right diaphragm pressure gauge will prove indispensable.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025