Nov . 22, 2024 05:01 Back to list

bellow differential pressure gauge factory

Understanding Below Differential Pressure Gauge A Comprehensive Overview

In the world of industrial measurement and monitoring, the below differential pressure gauge serves as an essential tool in ensuring system efficiency and operational safety. These devices are designed to measure the difference in pressure between two points within a system, which is crucial for a variety of applications, including HVAC systems, liquid and gas transmission, and filtration processes.

What is a Below Differential Pressure Gauge?

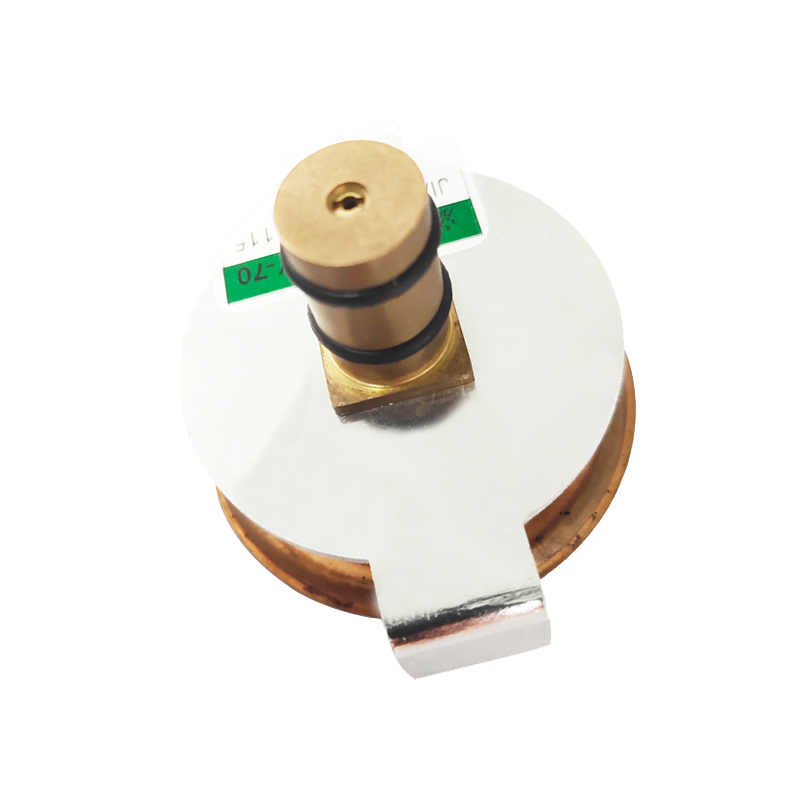

A below differential pressure gauge is specifically designed to measure the pressure drop across components such as filters, orifices, and valves. It provides valuable information about the performance of these components by indicating how much resistance they are imposing on the flow of the fluid or gas. This type of gauge is often specified for applications where monitoring the pressure difference is critical to ensure optimal operations.

The construction of below differential pressure gauges typically includes two pressure ports one for the inlet side (high pressure) and the other for the outlet side (low pressure). They are connected to a sensing mechanism that translates the pressure difference into a readable output, usually displayed on a dial or a digital screen.

Applications of Below Differential Pressure Gauges

The versatility of below differential pressure gauges makes them suitable for a wide array of applications

1. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these gauges are vital for monitoring air filters and ductwork systems. By assessing the differential pressure, technicians can determine when filters need replacing and ensure optimal air flow.

2. Fluid and Gas Transmission In pipelines that transport oil, gas, or water, maintaining the correct pressure differential is crucial for safe and efficient operations. Below differential pressure gauges can help detect leaks or blockages by monitoring the pressure changes.

3. Filtration Processes In various industries, including pharmaceuticals and food processing, maintaining the appropriate differential pressure across filters is vital for quality control. A sudden rise in pressure differential could indicate clogging, prompting timely maintenance actions.

4. Lab and Research Applications Many laboratory setups utilize below differential pressure gauges for monitoring pressure in experimental setups, ensuring precise control over environmental conditions.

bellow differential pressure gauge factory

Benefits of Using Below Differential Pressure Gauges

Investing in a reliable below differential pressure gauge comes with several advantages

- Real-Time Monitoring These gauges provide immediate feedback about the pressure conditions in a system, enabling maintenance personnel to act quickly if pressure abnormalities occur.

- Improved Efficiency By monitoring the pressure drop across various components, facilities can make informed decisions about maintenance and replacements, ultimately leading to improved efficiency and reduced downtime.

- Enhanced Safety Accurate pressure readings are crucial for ensuring the safety of industrial processes. By keeping track of pressure differentials, organizations can prevent failures and mitigate risks associated with operational hazards.

Choosing the Right Manufacturer

When selecting a below differential pressure gauge, it's essential to focus on quality and reliability. Various manufacturers specialize in pressure measurement devices, and it’s crucial to choose one that meets industry standards and possesses a strong reputation for accuracy. A reputable manufacturer will offer a range of products tailored to specific applications, along with robust customer support and service options.

Conclusion

In summary, below differential pressure gauges play a pivotal role in various sectors by providing critical information about pressure differences within systems. Their ability to ensure operational efficiency and safety makes them indispensable tools in industrial environments. As technology continues to advance, the design and functionality of these gauges are also likely to improve, offering even greater precision and ease of use for operators.

Investing in high-quality tools from a reliable manufacturer can significantly enhance system performance and safety, making below differential pressure gauges a worthwhile consideration for any industrial setup. Whether it’s for monitoring HVAC systems, fluid transmission, or filtration processes, these gauges will provide the necessary insights for effective management and maintenance. By understanding their function and applications, businesses can harness the power of this technology to optimize their operations and safeguard their processes.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025