Nov . 08, 2024 06:26 Back to list

Aerosense Differential Pressure Measurement Device for Accurate Environmental Monitoring

Understanding Aerosense Differential Pressure Gauge A Comprehensive Overview

In the modern world of industrial applications and process control, precise measurements are paramount. One of the key instruments used for this purpose is the differential pressure gauge. Among the many brands and models available in the market, the Aerosense differential pressure gauge stands out for its reliability and accuracy. This article delves into the functionality, applications, and advantages of the Aerosense differential pressure gauge, highlighting its significance in various industries.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points in a system. This device is crucial in applications where pressure differences are indicative of flow rates, filter conditions, and system efficiencies. The gauge displays the pressure difference in units such as pounds per square inch (PSI) or bar, allowing operators to monitor processes effectively.

The Aerosense Differential Pressure Gauge

Aerosense is known for manufacturing high-quality sensing equipment, and its differential pressure gauges are designed to meet the needs of various industries including HVAC (Heating, Ventilation, and Air Conditioning), pharmaceuticals, food and beverage, and petrochemicals. These gauges utilize advanced technology to provide accurate, real-time measurements, ensuring that operations run smoothly and efficiently.

Key Features

1. High Accuracy Aerosense differential pressure gauges are engineered for precision. Their design minimizes errors that can arise from environmental factors, making them suitable for critical monitoring and control.

2. Durability Built with robust materials, these gauges can withstand harsh industrial environments. This durability ensures long-term performance without frequent need for replacement.

3. User-Friendly Display Many models come equipped with easy-to-read digital displays or analog dial readings, providing immediate visibility of pressure readings. This feature is especially vital in high-paced environments where quick decision-making is crucial.

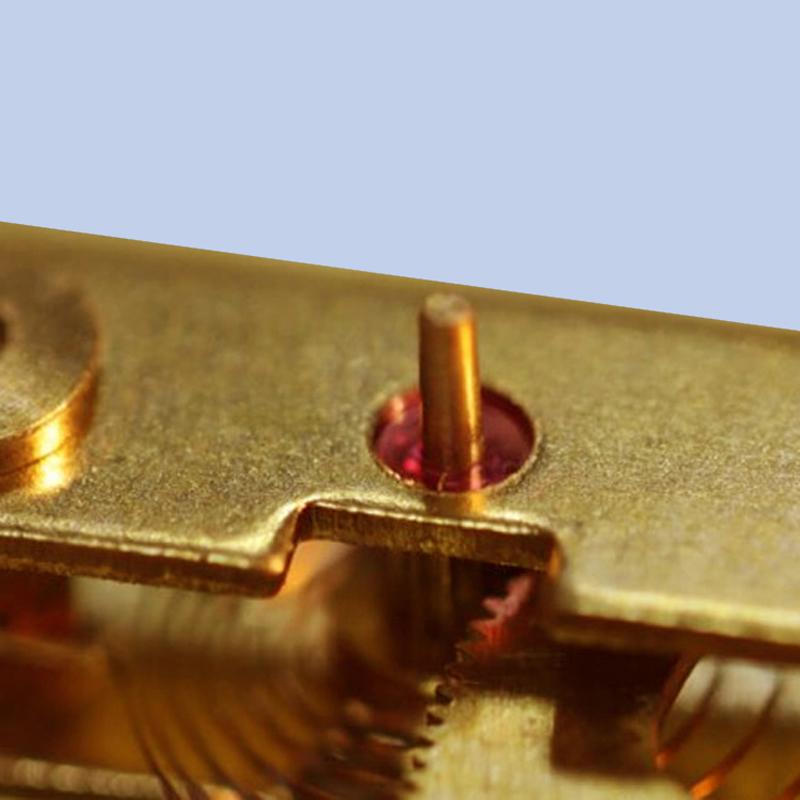

aerosense differential pressure gauge jah

4. Versatile Applications Aerosense gauges are versatile and can be used for various applications, including monitoring air filters, liquid level detection, and in safety systems where monitoring pressure differentials is essential to prevent system failures.

5. Customizability Aerosense understands that one size does not fit all. Their products can often be customized to meet the specific requirements of different applications, including various pressure ranges and sensor types.

Applications

The applications of Aerosense differential pressure gauges are wide-ranging

- HVAC Systems In HVAC systems, differential pressure gauges are used to monitor filter conditions. By measuring the pressure difference across a filter, technicians can determine when the filter is clogged and needs replacement, thus maintaining system efficiency.

- Pharmaceuticals In the pharmaceutical industry, maintaining sterile environments is critical. Differential pressure gauges help monitor air pressure differences between clean rooms and less clean areas, ensuring compliance with safety standards.

- Food and Beverage In food processing, these gauges measure the pressures involved in pneumatic systems that handle ingredients. Precise control helps ensure the safety and quality of food products.

- Petrochemicals In the petrochemical sector, differential pressure gauges are crucial for monitoring the flow and pressure of liquid hydrocarbons, ensuring optimal operation of equipment and processes.

Conclusion

The Aerosense differential pressure gauge is an indispensable tool in various industrial applications. Its ability to provide accurate readings in a user-friendly format ensures that operators can make informed decisions quickly. With its robust build, versatility, and advanced technology, the Aerosense gauge helps industries maintain efficiency, safety, and compliance. As technology continues to advance, instruments like the Aerosense differential pressure gauge are likely to evolve, further enhancing their performance and applications in the ever-demanding industrial landscape. Investing in high-quality measurement tools is essential for any organization aiming to optimize their processes and achieve operational excellence.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025